Sterilizing method and special microwave sterilization device for liquid food

A liquid food and microwave sterilization technology, which is applied in food preservation, preparation and application of alcoholic beverages, etc., can solve the problems of reducing operating costs and management costs, and achieve the effects of less difficult management, convenient use and safe process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

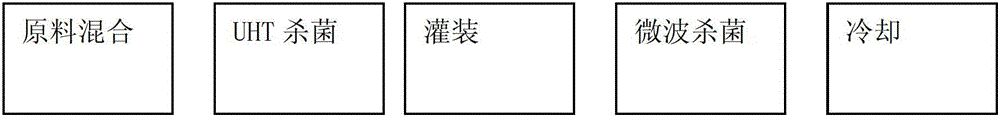

Image

Examples

Embodiment 1

[0020] Example 1: Orange juice is sterilized by UHT at 135°C, kept warm for 4-15 seconds, and finally cooled to 30-35°C for filling. After microwave sterilization for 3-5 minutes, it can be stored at room temperature, and the shelf life can reach more than 6 months.

Embodiment 2

[0022] The processing method of green tea: the temperature is 130-135 ℃ by ultra-high temperature instantaneous sterilization, heat preservation for more than 4 seconds, and finally cooled to 55-60 ℃ for filling; sterilized by microwave for 2-3 minutes, can be stored at room temperature, The shelf life can reach more than 6 months.

[0023] Special sterilization equipment for liquid food, including UHT or high temperature sterilization equipment, filling equipment and special tunnel microwave sterilization equipment. The microwave treatment box of the tunnel microwave sterilization equipment is equipped with a conveyor chain speed control device. The microwave generation power of the magnetron in the microwave processing box is controlled by the temperature control system; the microwave processing box is equipped with a magnetron power control switch, an observation window, a magnetron and a feed port. The microwave processing box is equipped with an observation window and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com