Glass electric kettle and method thereof

A technology for glass electric appliances and kettles, which is applied to cooking utensils, household utensils, applications, etc. It can solve the problems of high cost, difficult assembly, and poor sealing, and achieve the effects of improving quality, low cost, and preventing loose sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

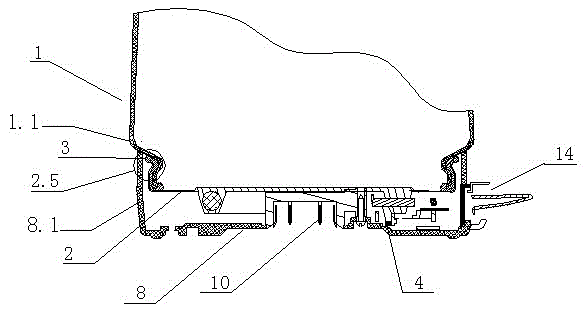

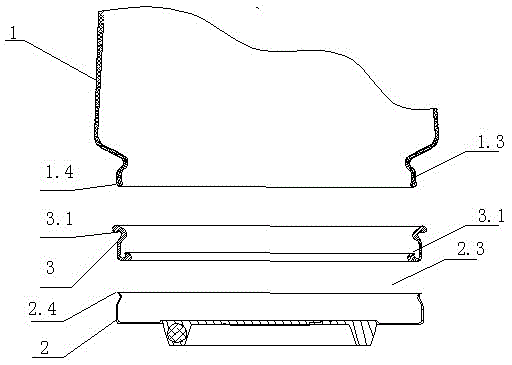

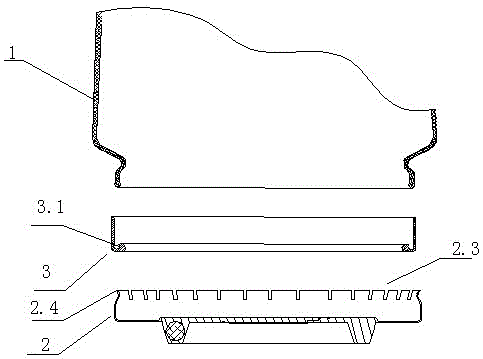

[0035] see Figure 1-Figure 8 , the glass electric kettle comprises a body 1, a heating plate 2, a silicone sealing ring 3, a coupler 10 and a bottom cover 8 thereof, and the body 1 is made of glass. The main body opening 2.1 at the lower part of the main body 1 is provided with a heating plate 2 and a silicone sealing ring 3 for sealing connection. It is arranged around the periphery of the heating plate, and the annular opening 2.3 is provided with an annular opening flange 2.4, and the annular opening flange 2.4 is arranged around the periphery of the heating plate. Slit legs; the slit legs are squeezed inward by the contraction member 6, the annular inner diameter of the slit legs is smaller than the outer diameter of the silicone sealing ring 3 after extrusion, the slit legs are evenly arranged on the annular opening flange 2.4, and the silicone seal ring 3 is set between the heating plate 2 and the opening 2.1 of the main body, and the fixed position 3.1 is positioned i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com