Nano heavy calcium carbonate grinding aid dispersion polymerization inhibitor and its preparation method and application

A technology of heavy calcium carbonate and polymerization inhibitor, which is applied in the direction of fiber dispersant addition, textile and papermaking, pigmented coating, etc. It can solve the problems that cannot meet the demand, reduce energy consumption and deposition problems, and reduce energy consumption and dielectric loss, the effect of low particle surface free energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

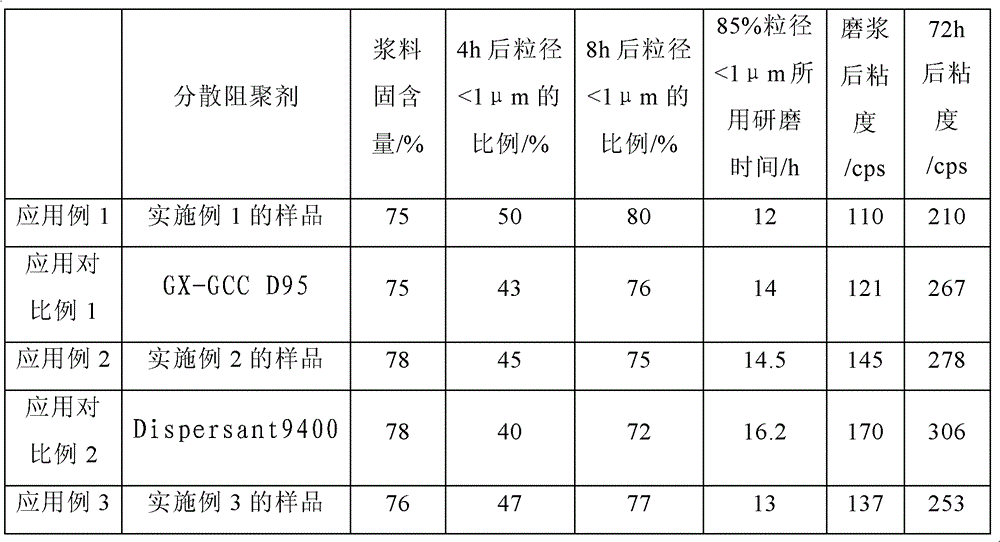

Examples

Embodiment 1

[0029] Preparation of polyepoxysuccinic acid monomer: Add 10kg of maleic anhydride to 3.5kg of sodium hydroxide and 15kg of deionized water to hydrolyze the maleic anhydride into sodium maleate, then add 0.2 kg sodium tungstate and 3kg hydrogen peroxide (30% by weight concentration) dropwise at the same time, the dropwise addition is completed within 60 minutes, and the temperature is lowered to normal temperature after 30 minutes of heat preservation, and diluted with water until the weight percent concentration of polyepoxysuccinic acid monomer is 10% .

[0030] Preparation of nano heavy calcium carbonate grinding aid dispersion polymerization inhibitor: 300kg acrylic acid monomer, 30kg prepared polyepoxysuccinic acid monomer and deionized water are mixed to form a reactant whose concentration is 30% by weight of acrylic acid monomer Monomer solution A; mix 8kg sodium persulfate, 4kg ammonium persulfate and 20kg deionized water to make oxidizing agent solution B, mix 48kg so...

Embodiment 2

[0032] Preparation of polyepoxysuccinic acid monomer: Add 22.5kg of maleic anhydride to 11.25kg of sodium hydroxide and 37kg of deionized water to hydrolyze the maleic anhydride into sodium maleate, then heat up to 80°C and add to the resulting mixture 0.9kg of sodium tungstate and 9kg of hydrogen peroxide (30% by weight concentration) are added dropwise at the same time, the dropwise addition is completed within 120 minutes, and the temperature is lowered to normal temperature after 30 minutes of heat preservation, and diluted with water until the concentration of polyepoxysuccinic acid monomer is 15% by weight. %.

[0033] Preparation of nano heavy calcium carbonate grinding aid dispersion polymerization inhibitor: 250kg acrylic acid monomer, 75kg prepared polyepoxysuccinic acid monomer and deionized water are mixed to form a reactant whose concentration is 21% by weight of acrylic acid monomer Monomer solution A; mix 6kg sodium persulfate, 3kg ammonium persulfate and 20kg d...

Embodiment 3

[0035]Preparation of polyepoxysuccinic acid monomer: Add 15kg of maleic anhydride to 6kg of sodium hydroxide and 24kg of deionized water to hydrolyze maleic anhydride into sodium maleate, then add 0.45kg to the resulting mixture after heating up to 70°C Sodium tungstate is added dropwise with 6kg hydrogen peroxide (30% by weight concentration) at the same time. The dropwise addition is completed within 100 minutes. After 30 minutes of heat preservation, it is lowered to normal temperature, and diluted with water until the concentration of polyepoxysuccinic acid monomer is 30% by weight.

[0036] Preparation of nano heavy calcium carbonate grinding aid dispersion polymerization inhibitor: 250kg acrylic acid monomer, 50kg prepared polyepoxysuccinic acid monomer and deionized water are mixed to form a reactant whose concentration is 12% by weight of acrylic acid monomer Monomer solution A; mix 6kg sodium persulfate, 3kg ammonium persulfate and 10kg deionized water to make oxidant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com