Production method for anti-counterfeiting paper

The technology of one paper and the other side, applied in papermaking, paper coatings, textiles and papermaking, etc., can solve the problems of slow production speed, difference in paper transparency, difficult UV curing, etc., and achieve the effect of excellent anti-counterfeiting effect and uniform thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

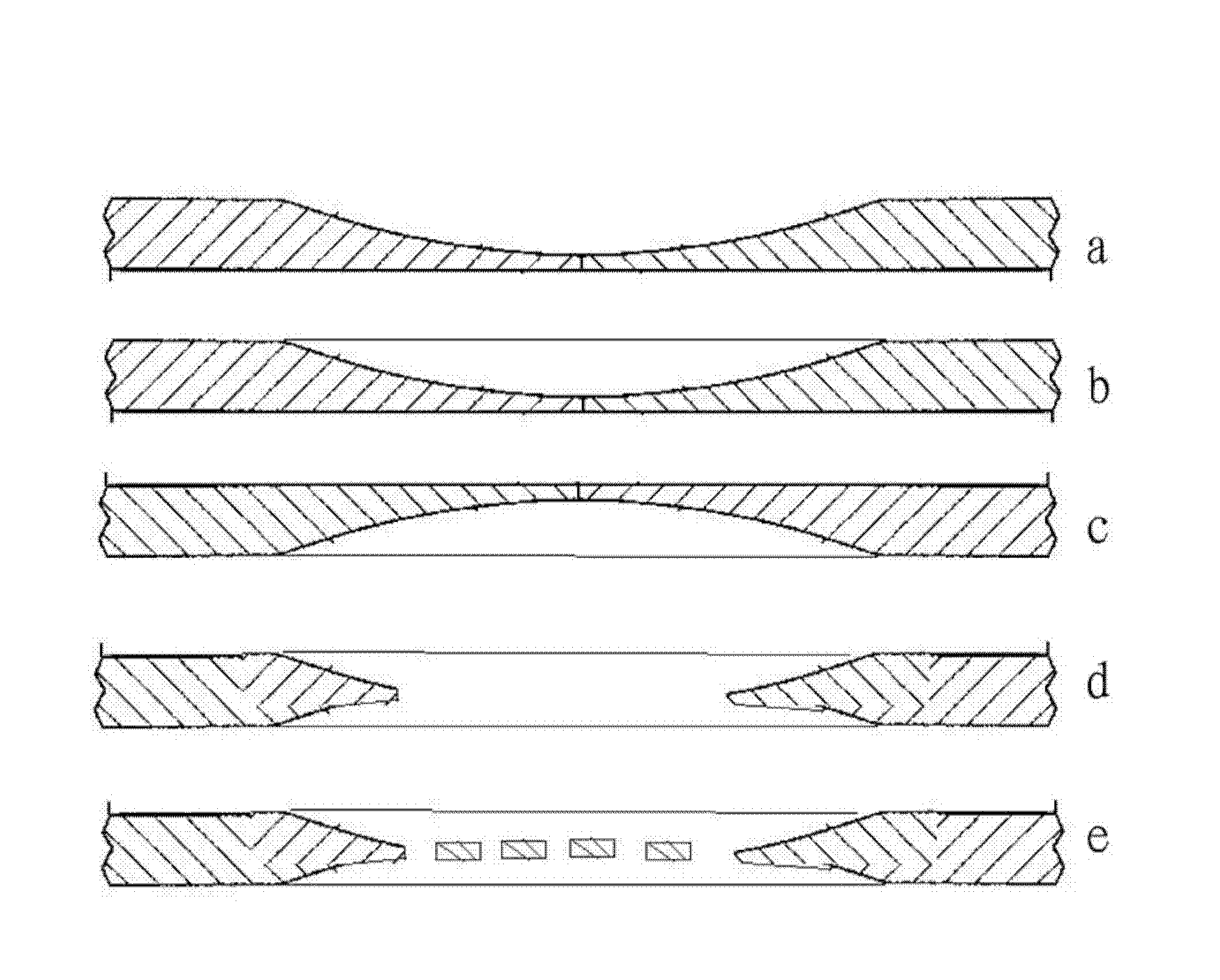

[0081] Below, refer to figure 1 This Example 1 will be described.

[0082] First, the commercially available paper is thinned by using the thinning step of US4814043, so as to obtain the paper with the structure shown in a. Then, a first coating material is applied to the thinned paper by screen printing to obtain a paper having a structure as shown in b. Turn the paper over to get the paper shown in c. Repeating the thinning step (to expose the first coating material) and the application step with this inverted sheet results in a sheet with a security window as shown in d. The specific composition of the first coating material described here is shown in Table 1, and the content percentage is in weight, the same below.

[0083] The composition of the first coating material in table 1 embodiment 1 (suitable for UV curing screen printing)

[0084] Material

Embodiment 2

[0086] Basically the same as Example 1, but the difference is that, by controlling the depth of thinning or applying the coating material, to have a window containing a hollow paper image as shown in e (the specific steps are carried out with reference to US4814043, no longer here Repeat), so as to obtain a transparent or translucent window effect.

Embodiment 3

[0088] It is basically the same as in Example 1, but the difference is that the coating material is applied by means of blade coating (see Table 2 for its composition), and the first and second coating materials are the same, and the paper with the anti-counterfeit window shown in d is still obtained .

[0089] The composition of coating material among the table 2. embodiment 3 (applicable to UV curing blade coating process)

[0090] Material

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com