Guide bearing structure of hot water circulation pump

A technology of hot water circulation pump and guide bearing, which is applied to parts, pumps, and pump components of pumping devices used for elastic fluids. It can solve the problems of guide bearings being impacted and easily damaged, and achieve energy saving and reliable performance. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

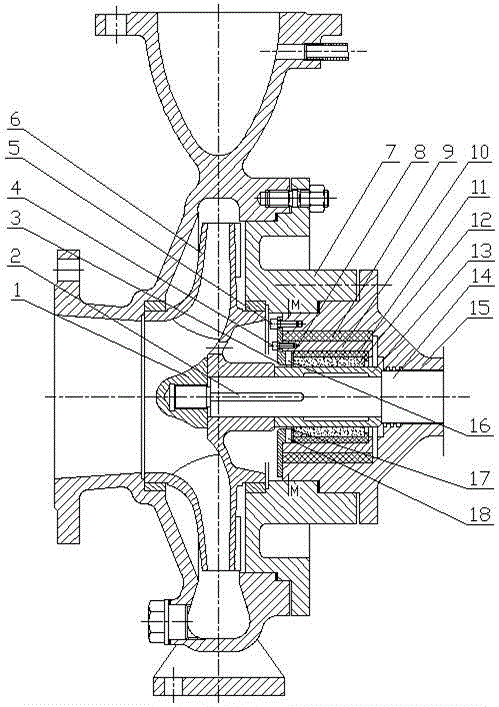

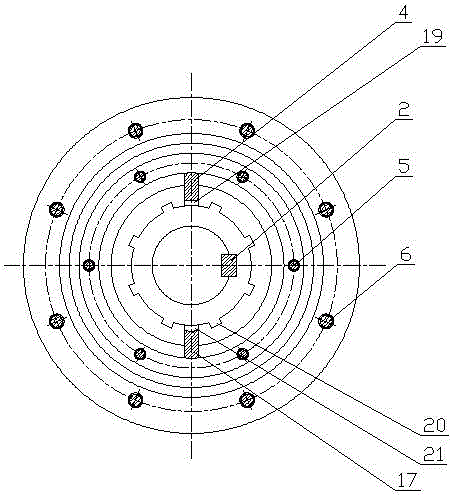

[0009] Referring to the accompanying drawings, its structure includes a shaft sleeve 13, a main shaft 14, an impeller nut 1, a key 2, an anti-rotation plate 3, an impeller 6, a pump cover 7, A rubber plate 8, a rubber damper 9, a protective bracket 10, and a protective cover 11. Ceramic sleeve 12, shaft sleeve 13, bearing seat 15, A card slot 19, B card slot 21, B rubber plate 17, wherein the shaft sleeve 13 is set on the main shaft 14 through the key 2 for circumferential fixing, and the impeller nut 1 Rotate on the main shaft 14, press the shaft sleeve 13 on the main shaft 14 through the impeller 6, and fix it axially. The ceramic sleeve 12 is installed in the protective sleeve 11, and the protective sleeve 11 is pressed into the protective bracket 10, and the protective bracket 10 is installed in the Inside the rubber damping body 9, the rubber damping body 9 is pressed into the bearing seat 15, A rubber plate 8 is placed in the A card slot 19, B rubber plate 17 is placed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com