Plate-type wet air cooler

An air cooler and plate-type technology, which is applied in the direction of water shower coolers, direct contact heat exchangers, heat exchanger types, etc., can solve the problems of spray pipeline nozzle clogging and entering the water tank, etc., to achieve enhanced heat transfer performance and reduce The effect of small power loss and convenient assembly

Inactive Publication Date: 2013-07-03

GANSU LANPEC TECH +3

View PDF9 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

On the contrary, small particle-sized and needle-shaped impurities, including dead branches and rotten leaves, sand, gravel, soil, and welding slag and iron chips generated during the production process, may enter the water tank. These impurity particles will cause spray pipelines and nozzle clogging

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

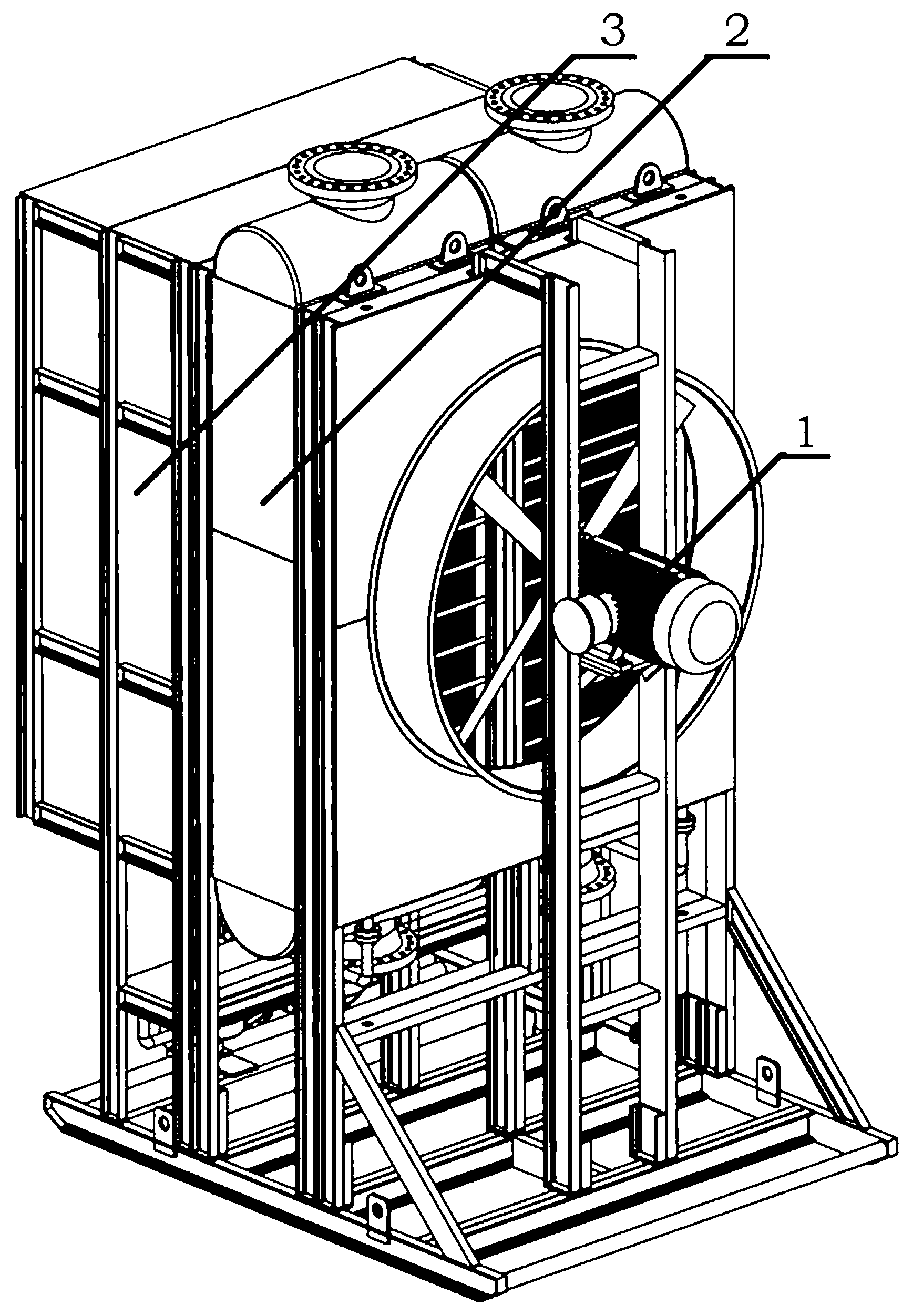

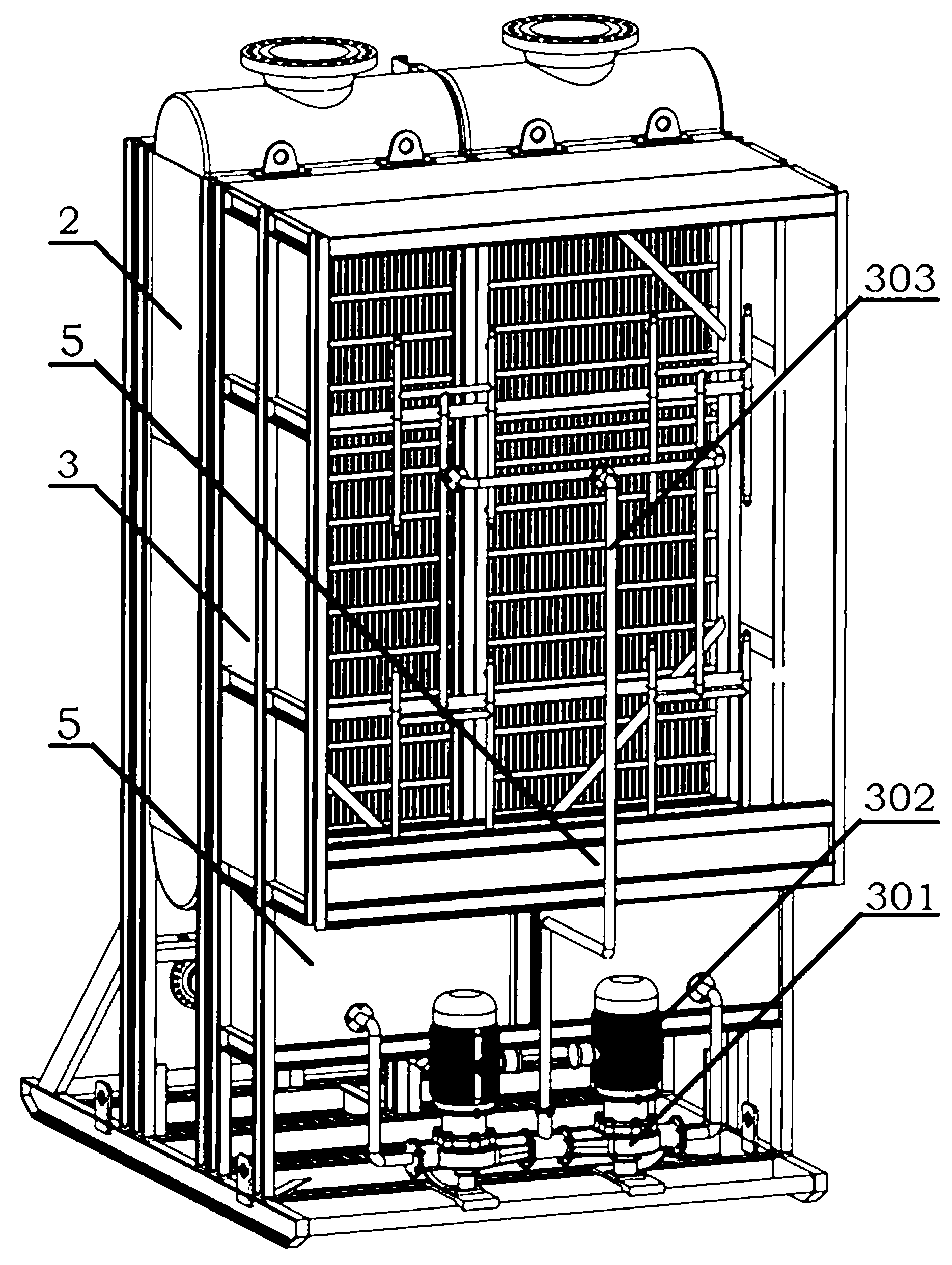

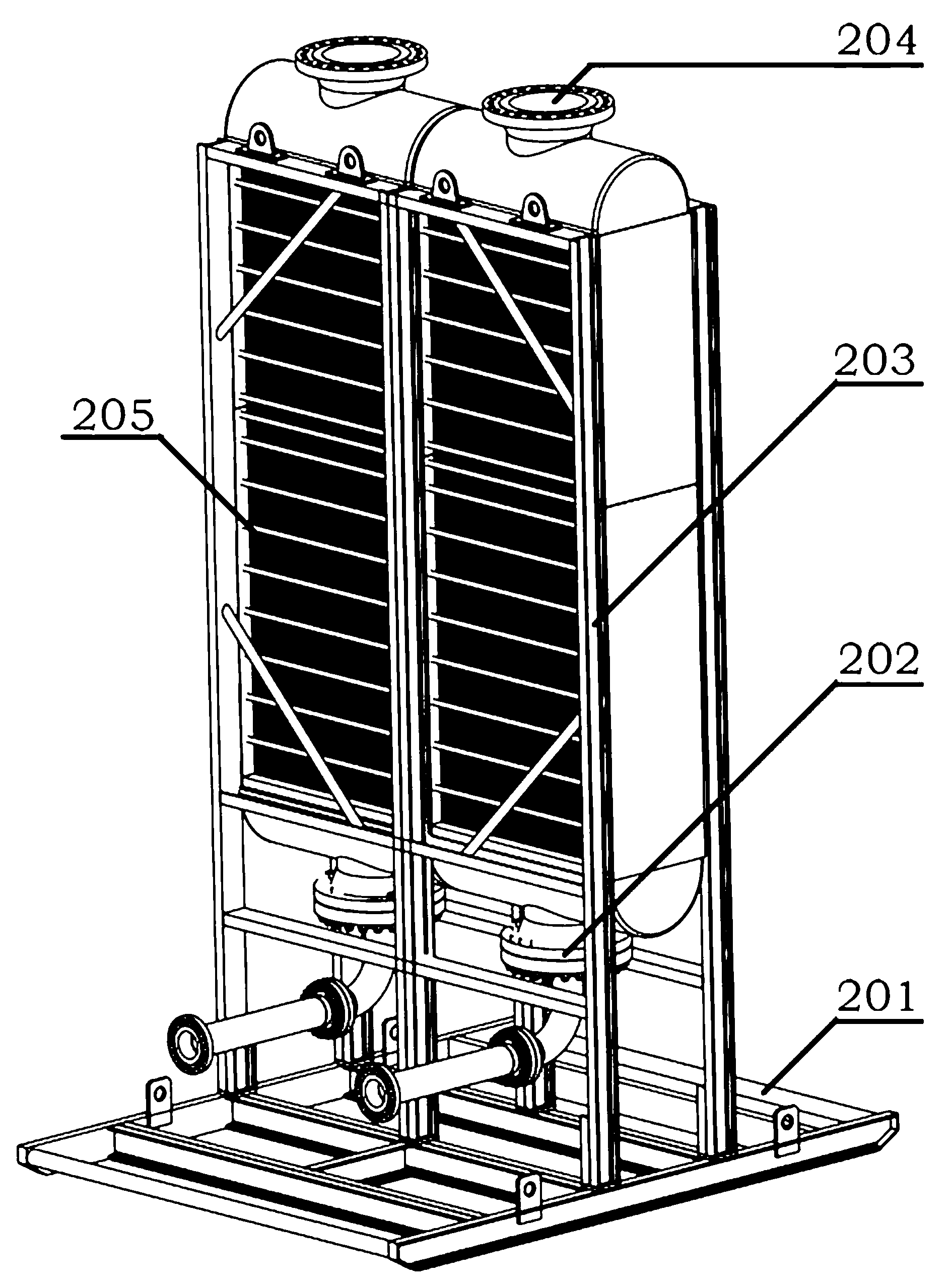

The invention discloses a plate-type wet air cooler which comprises an air conditioning system, a heat exchange system and a spray system, wherein the plate bundle of the heat exchange system is mainly formed by stepped corrugated plates and inserts. Every two stepped corrugated plates are interlocked; the long edges of the stepped corrugated plates are welded and formed plate cavities or plate pipes form a channel for the circulation of thermal media. Every two plate pipes are superposed, the two adjacent short edges of the two plate pipes are welded and the inserts are welded at the corner angles; and the formed plate cavities form a channel for the circulation of air. According to the plate-type wet air cooler, the heat transfer plate bundle is formed by the stepped corrugated plates which are made of materials such as stainless steel, titanium plate and the like, so that the heat exchange performance of the air cooler is strengthened; and the plate-type wet air cooler has excellent using properties such as corrosion resistance, high temperature resistance and high pressure resistance.

Description

technical field [0001] The invention belongs to the technical field of equipment manufacturing, and in particular relates to a heat exchanger, in particular to a plate type wet air cooler. Background technique [0002] The plate type wet air cooler is an advanced air cooling product in the world at present, and is widely used in the cooling of low-temperature end media in petroleum, petrochemical and other industries. Patent CN01201689.6 is the first plate-type air cooler in the world, which has epoch-making significance. Based on the limitations of primary products, this patent also has problems such as easy water accumulation on the workbench, easy blockage of nozzles, insufficient atomization of spray water droplets, poor air humidification performance, poor heat transfer performance, plate bundles are not resistant to high temperature and high pressure, etc. Many defects bring inconvenience to the use and maintenance of the air cooler. What is particularly prominent is...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): F28D9/00F28F25/02F28F25/10

Inventor 张延丰常春梅陈韶范胡国栋

Owner GANSU LANPEC TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap