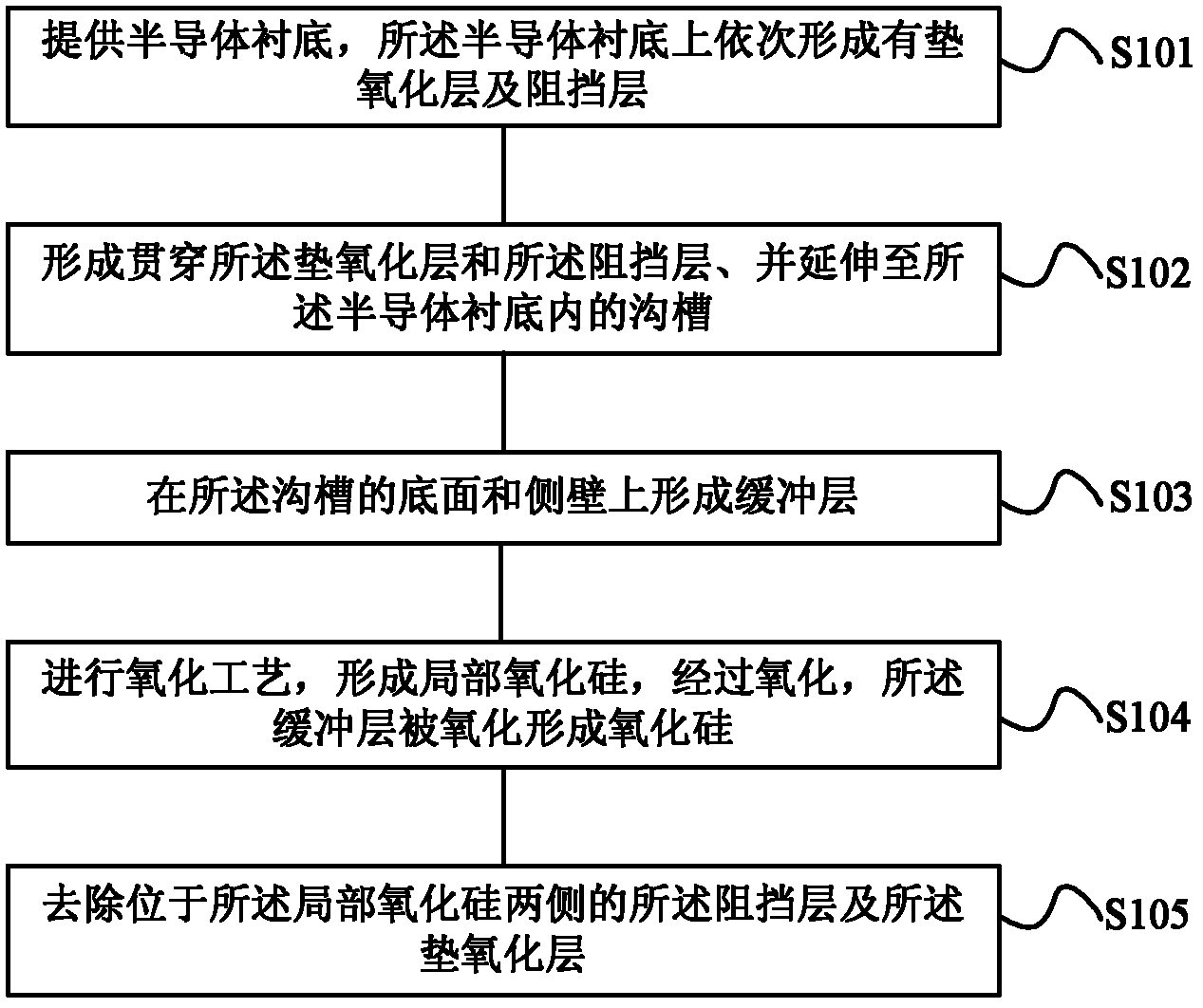

Forming method of locally oxidized silicon isolation

A technology of local silicon oxide and pad oxide layer, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problem of large bird's beak effect, and achieve the effect of reducing consumption and reducing bird's beak effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In the embodiments of the present invention, by forming a buffer layer covering the sidewall of the trench, the lateral intrusion of oxygen atoms is prevented and the bird's beak effect is reduced. Moreover, the buffer layer can provide a certain amount of silicon material for the formation of local silicon oxide. During the oxidation process, the consumption of the substrate is reduced, thereby further reducing the bird's beak effect.

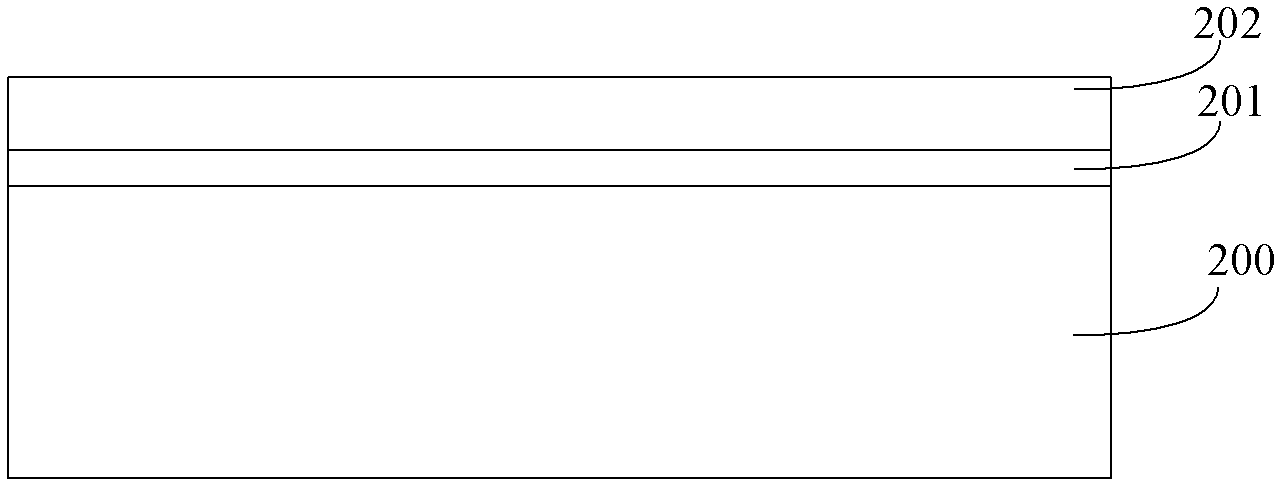

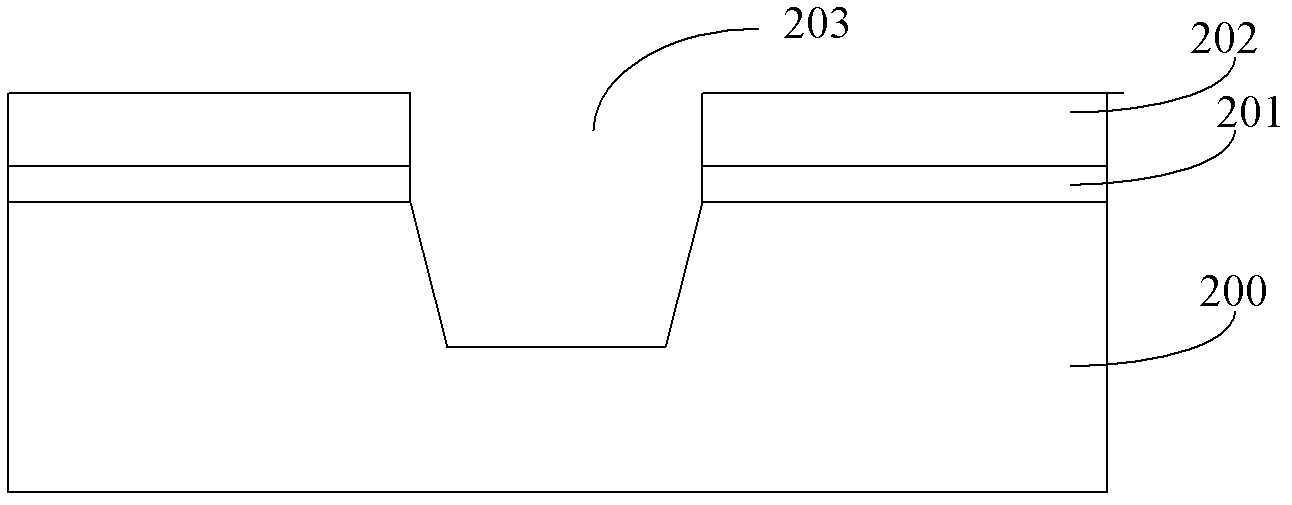

[0026] In order to make the above objects, features and advantages of the present invention more clearly understood, the embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The following description sets forth numerous specific details in order to provide a thorough understanding of the present invention. However, the present invention can be implemented in many other ways different from those described herein, and those skilled in the art can make similar promotions withou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com