Hard coat film and front surface protective plate

A technology of hard coating and substrate film, which is applied in the direction of coating, layered products, and layered product processing, etc. Good effect with excellent surface hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

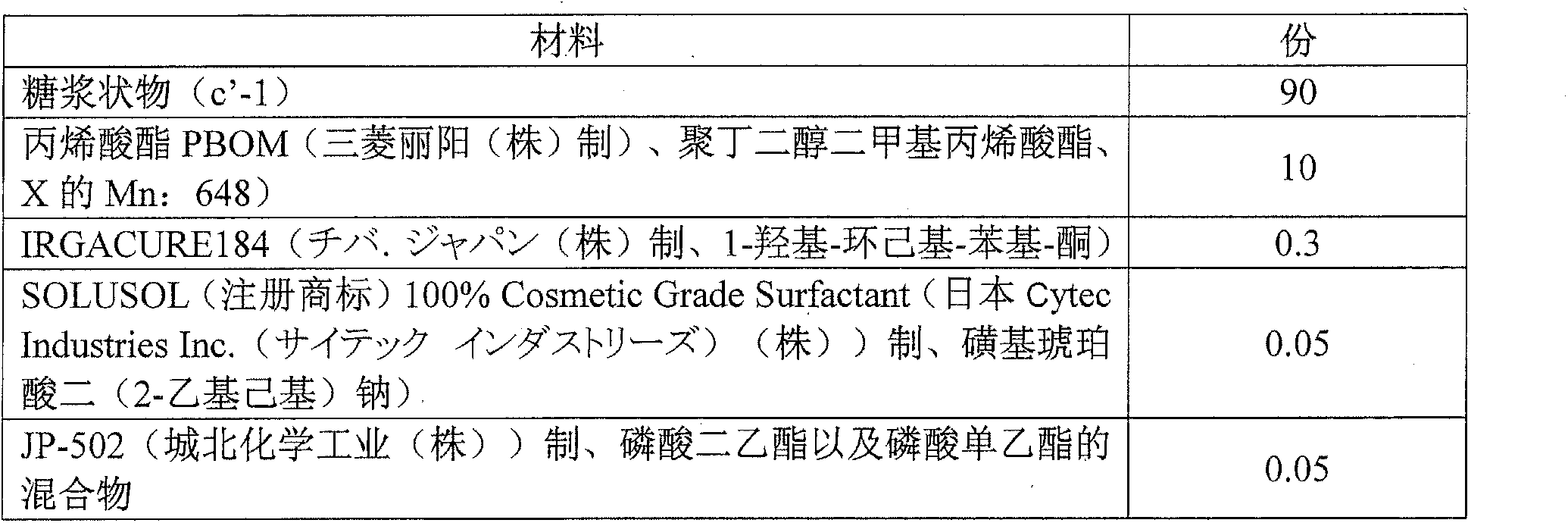

Embodiment 1

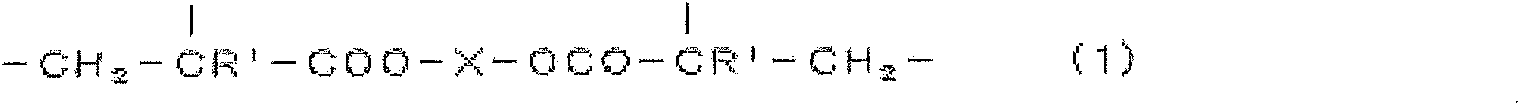

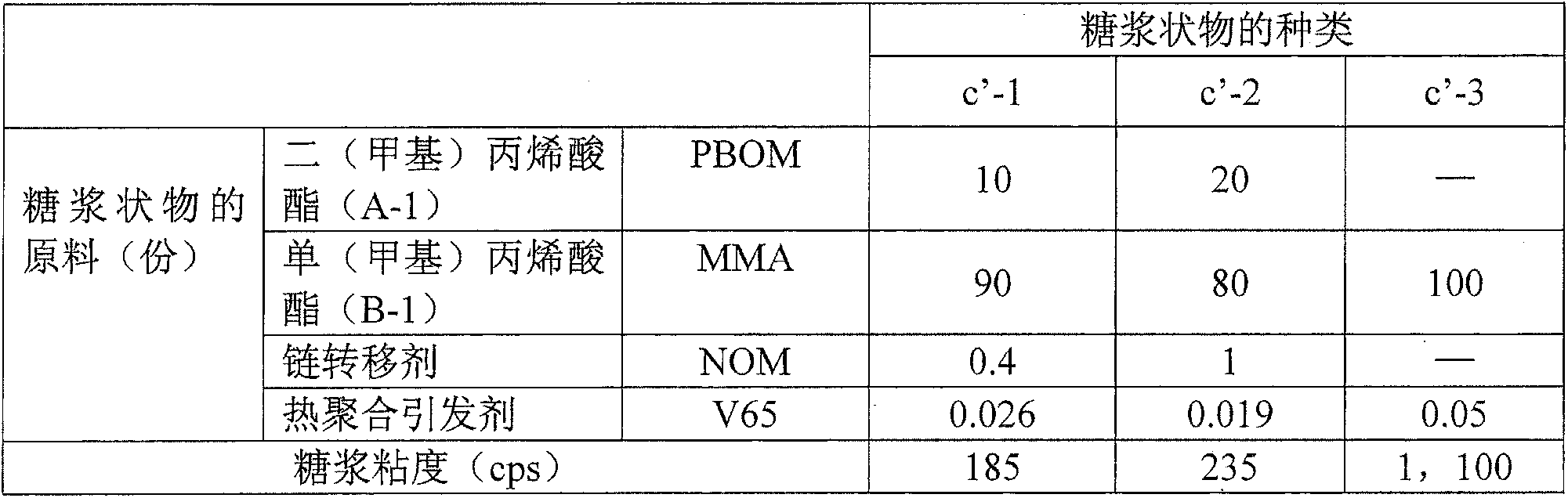

[0108] (1) Preparation of monomer raw materials for base film

[0109] In a reactor equipped with a condenser, a thermometer, and a stirrer, polytetramethylene glycol dimethacrylate (manufactured by Mitsubishi Rayon Co., Ltd., Acrylate PBOM) 10 parts, 90 parts of methyl methacrylate (manufactured by Mitsubishi Rayon Co., Ltd., acrylate M) as mono(meth)acrylate (B-1), and n-octyl sulfide as chain transfer agent 0.4 part of alcohol (manufactured by Elphatochem Japan Co., Ltd., NOM) was stirred, and heating was started.

[0110] When the temperature in the reactor reached 70°C, 2,2'-azobis(2,4-dimethylvaleronitrile) (manufactured by Wako Pure Chemical Industries, Ltd., V65) 0.026 Next, after raising the temperature in the reactor to 80° C. and maintaining it for 60 minutes, the temperature in the reactor was rapidly cooled to room temperature using a large amount of ice water to obtain a syrup (c′-1). The viscosity of the syrup (c'-1) at 25°C was 185 cps. The results are sho...

Embodiment 2~5 and comparative example 1

[0128] A syrup (c'-2) was produced in the same manner as in Example 1 except that the raw material of the syrup was changed to the conditions shown in Table 1. Using the syrup shown in Table 1, the composition of the monomer raw material for the base film and the thickness of the hard coat layer were changed to the conditions shown in Table 4. In Comparative Example 1, a hard coat layer could not be formed. Except for these conditions, it carried out similarly to Example 1, and obtained the hard coat film, respectively. Table 4 shows the evaluation results of each hard coat film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com