Control valve having a variable nozzle cross-section for automatic compressed-air brakes

A technology of compressed air and control valves, which is applied in the direction of brakes, automatic starting devices, control valves and air release valves, etc., which can solve the problems of dangerous longitudinal force of trains and ineffective acceleration of signal transmission, so as to achieve high operation safety and realize operation Safety, avoiding the effect of dangerous longitudinal forces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

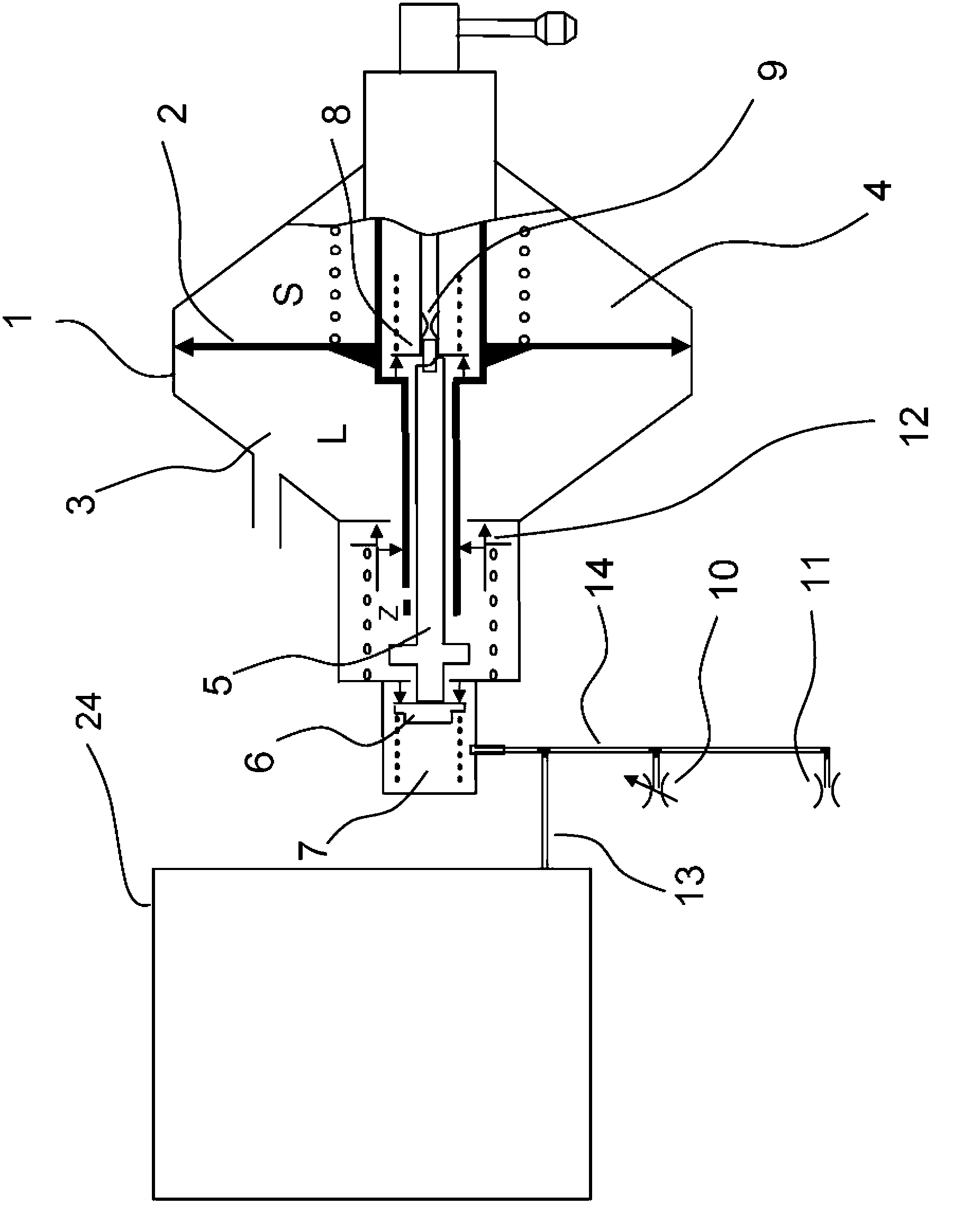

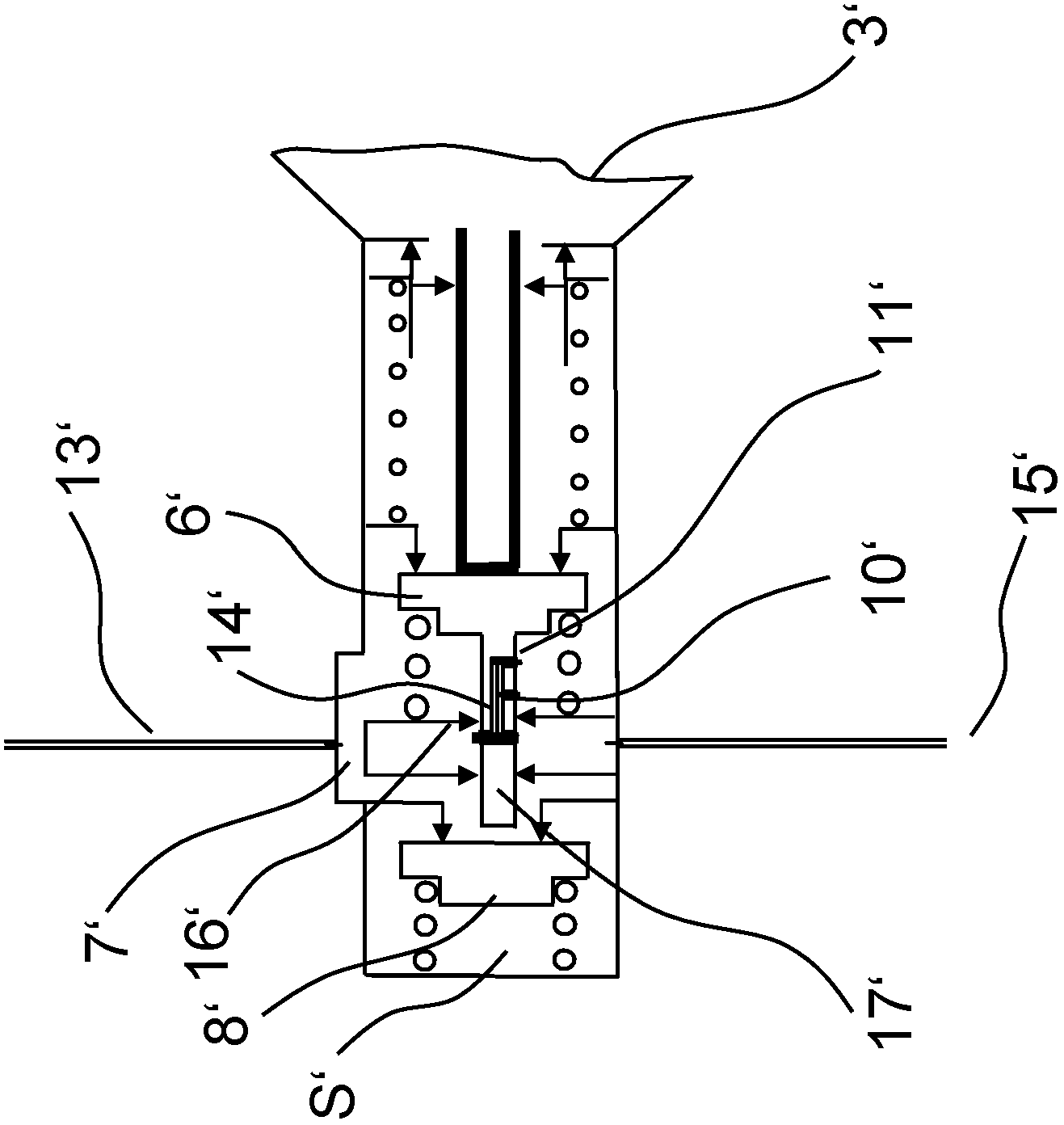

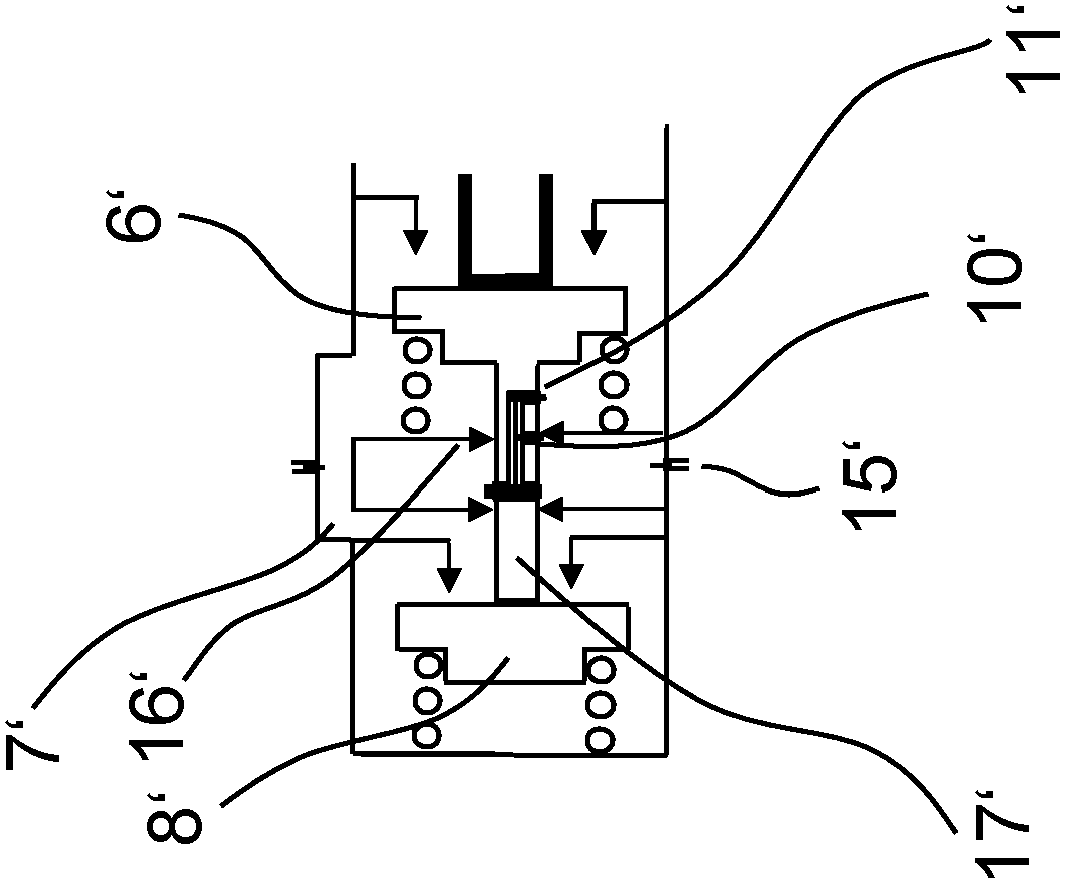

[0037] according to figure 1 The dual pressure unit 1 shown here, also called line valve, of the pneumatic control valve has a control piston 2 which is acted upon from one side with main air line pressure L via a first control chamber 3 . The reference pressure S present in the associated second control chamber 4 acts on the control piston 2 from the opposite side. Protruding from the control piston 2 is a rod 5 which actuates an accelerator valve 6 with its end.

[0038] The rod 5 is supported here on a vent valve 8 for the reference pressure S, which is held closed by a compression spring. This stage clip is stronger than the stage clip of accelerator valve 6, so accelerator valve is opened at first. By opening the accelerator valve 6 with the rod 5 of the control piston 2, braking acceleration takes place by additionally compressing air from the main air line L via the non-return valve 12 and the channel KZE7 integrated in the line part 1 (additional row air passage) in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com