Method and apparatus for pressure testing a pipe joint

A pressure test and equipment technology, which is applied in the direction of using liquid/vacuum for liquid tightness measurement, pipe/pipe joint/pipe fitting, mechanical equipment, etc., can solve the problems of high consumption, large energy consumption, large pipeline volume, etc. Achieving good protection and low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

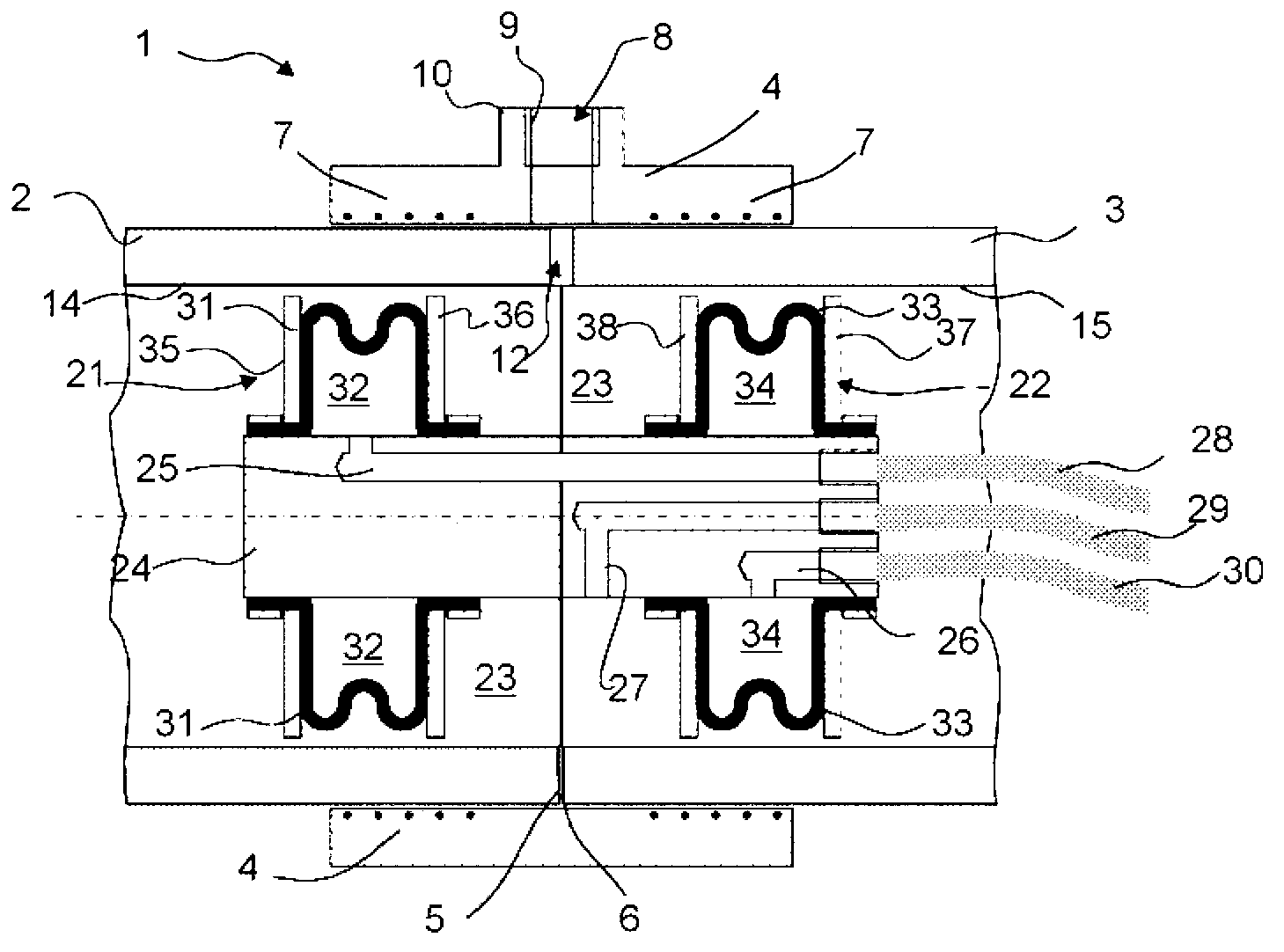

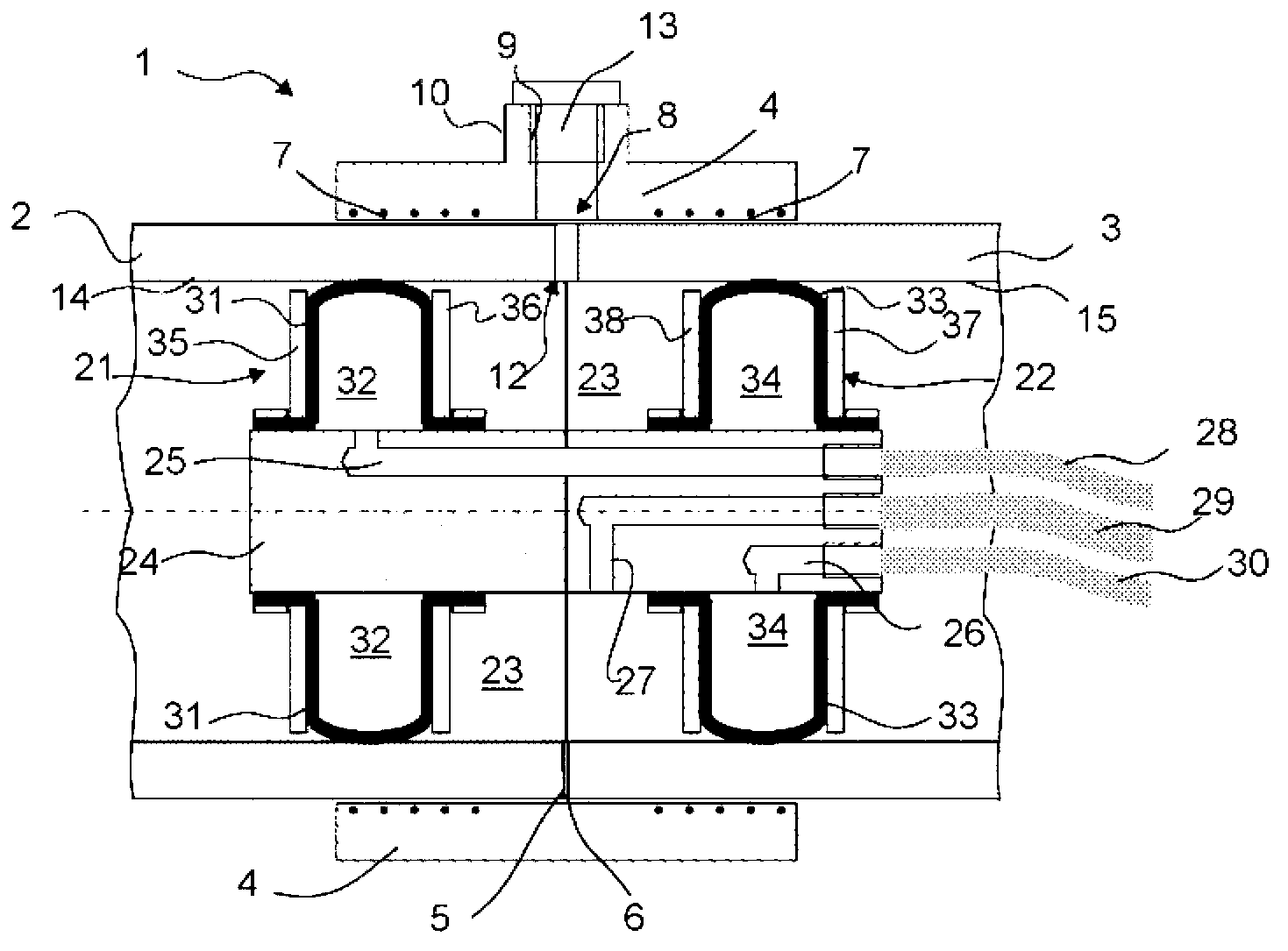

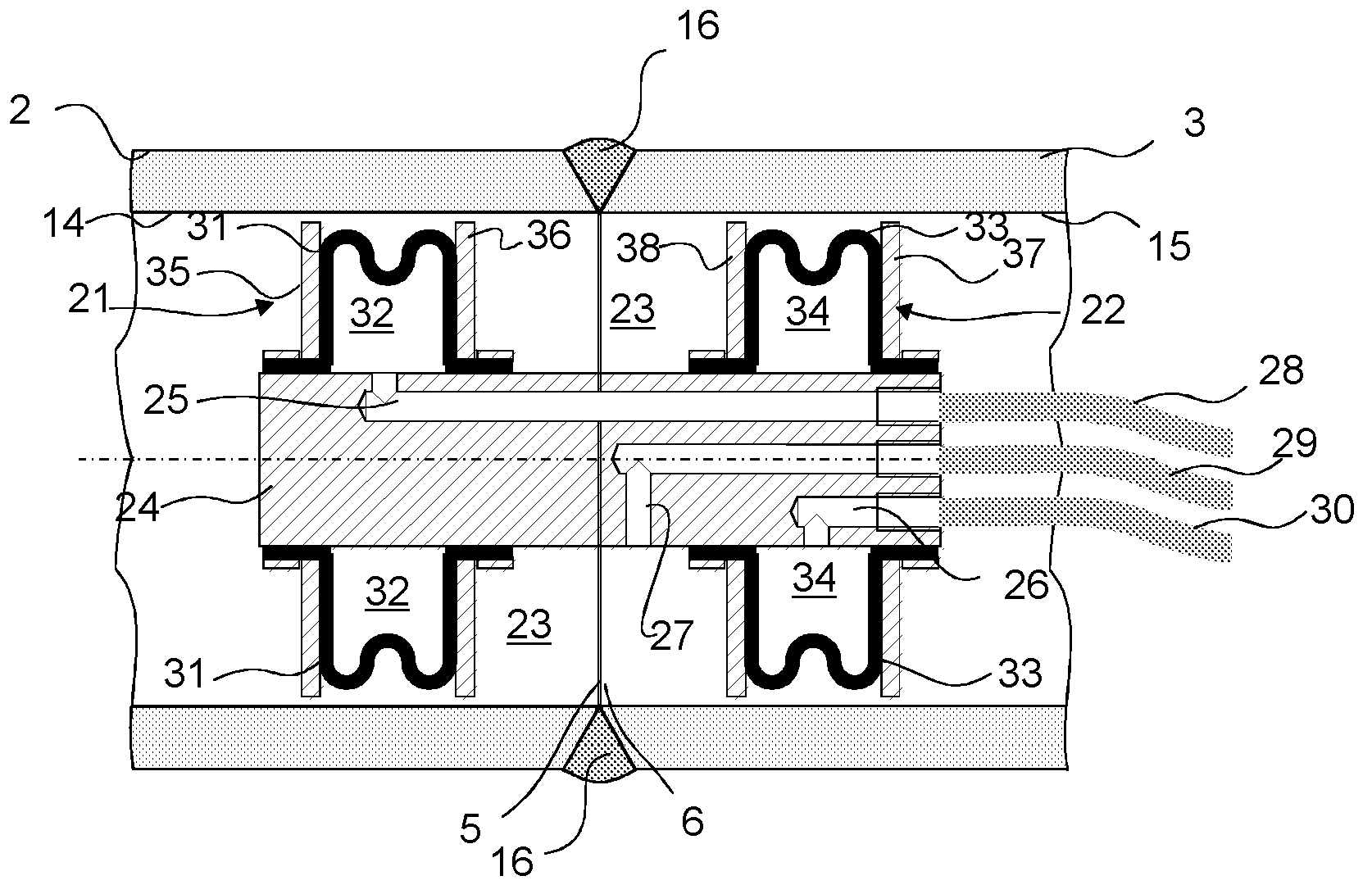

[0015] figure 1 and 2 A cutaway portion of the pipe joint 1 to which the sleeve portion 4 is applied is shown. In this joint two pipe parts 2 and 3 are joined together end-to-end, in which case the abutting end 5 of the first pipe part 2 abuts against the abutting end 6 of the second pipe part 3 . Adjacent end sections of the pipe parts 2 , 3 are arranged in bushings, ie in the sleeve part 4 . The bushing portion 4 includes heating means 7, such as thermal resistance wires 7, which become heated when electric current is conducted to them. A connection point (not shown) per se belonging to the state of the art may be arranged in the bushing part 4 , said connection point being connected to a thermal resistance wire and to which connection point the current is communicated. Due to the heating by the heating means 7 , typically a resistance wire, a joint is formed between the sleeve part 4 and the tube parts 2 , 3 in a manner known per se from the prior art. In the connection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com