Suspension type hydraulic profiling flower and fruit thinning machine and usage method thereof

A technology of flower thinning and fruit thinning, hydraulic profiling, applied in the directions of botanical equipment and methods, applications, agricultural machinery and implements, etc. To achieve the effect of saving operation labor and artificial adjustment time of position, reducing labor intensity and labor demand, and compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

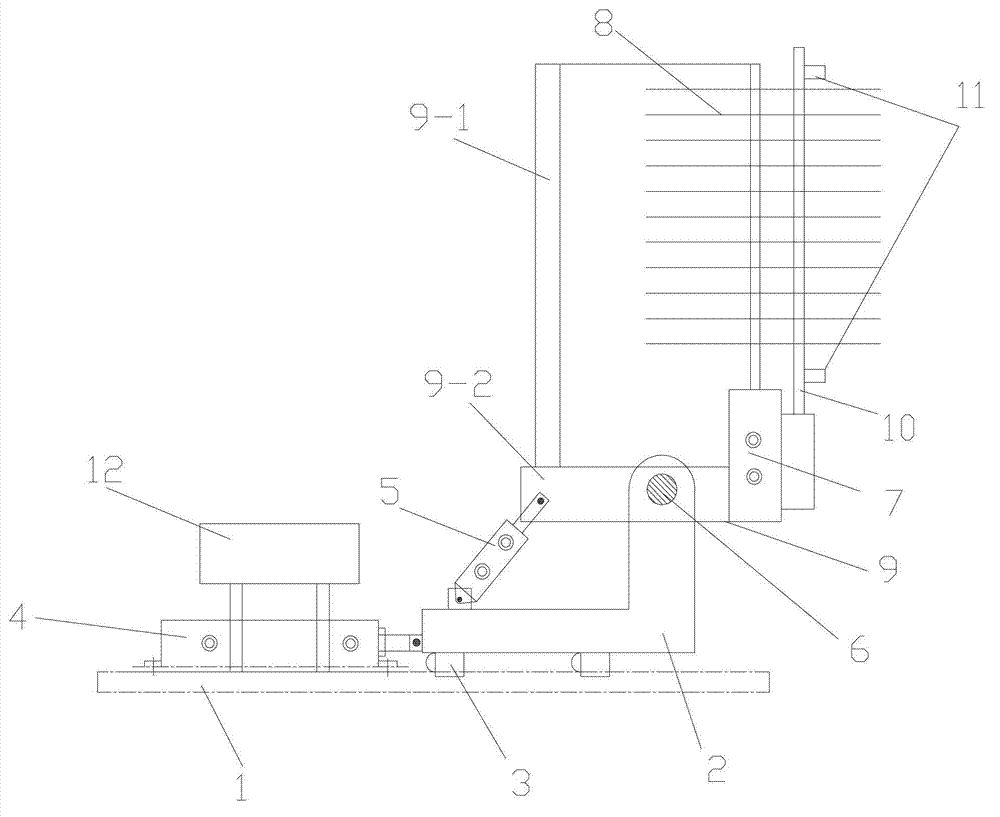

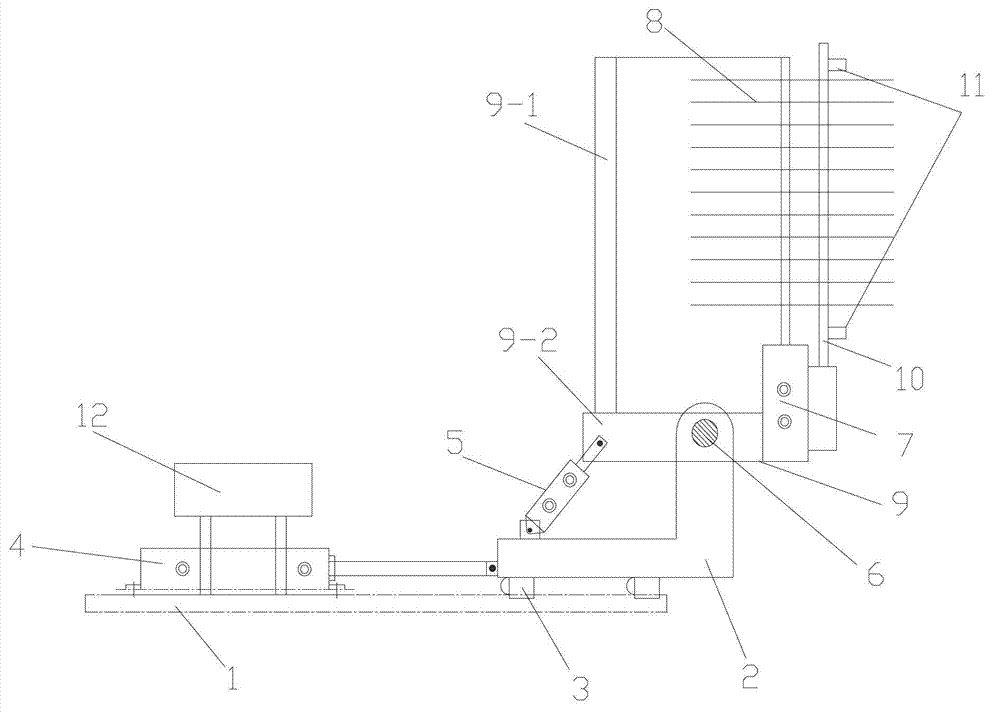

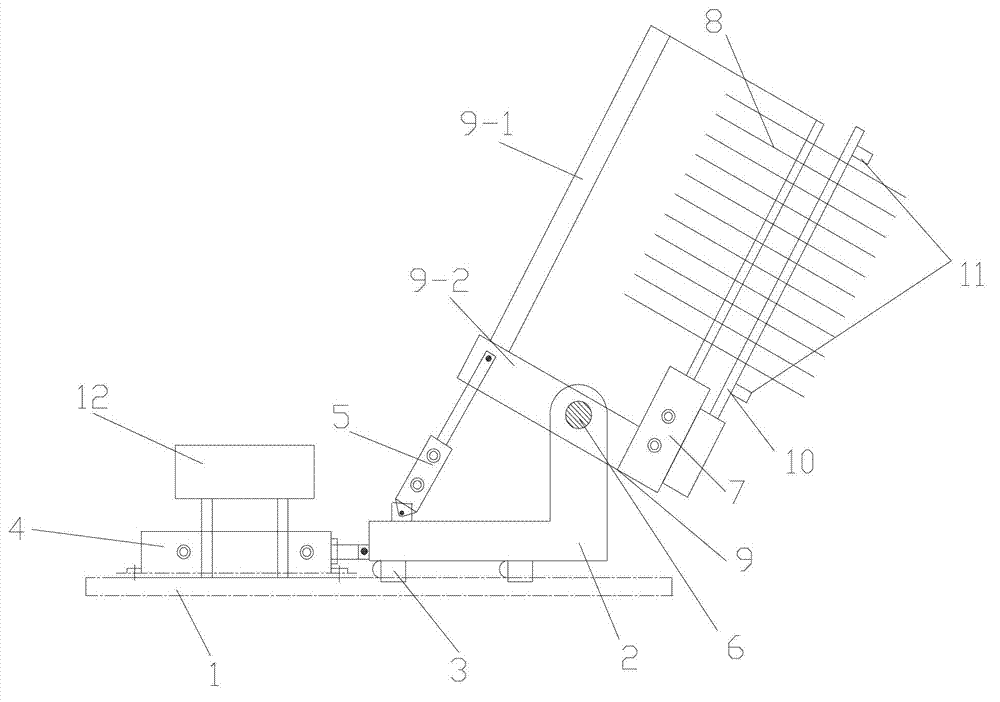

[0033] This embodiment is a kind of suspended hydraulic profiling flower thinning and fruit thinning machine, its structure is as follows: figure 1 As shown, it includes a suspension frame 1, a movable frame 2, a push-out hydraulic cylinder 4, a profiling hydraulic cylinder 5, a flower and fruit thinning mechanism, a hydraulic control device 12 and a detection rod assembly; the movable frame 2 is arranged on the suspension frame 4 through a guide rail 3 , the push-out hydraulic cylinder is set on the suspension frame and connected with the movable frame, the profiling hydraulic cylinder is set on the movable frame and connected with the flower and fruit thinning mechanism, and the flower and fruit thinning mechanism is also connected with the movable frame through the rotating shaft 6, and the detection rod assembly It is located on the side of the flower and fruit thinning mechanism; the push-out hydraulic cylinder, the profiling hydraulic cylinder and the flower and fruit thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com