Continuous stamping forming die for large-area metal bipolar plate of fuel battery

A large-area metal, stamping and forming technology, applied in the field of manufacturing molds, can solve the problem of inconsistent forming height of runner grooves, and achieve the effects of improving transportation stability, preventing slippage, and high processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

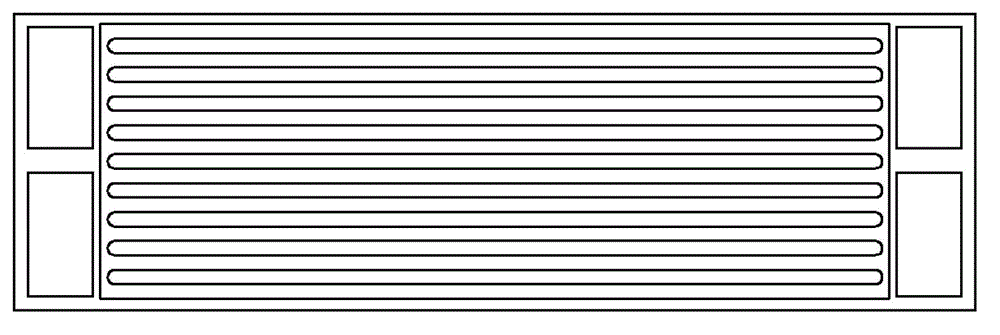

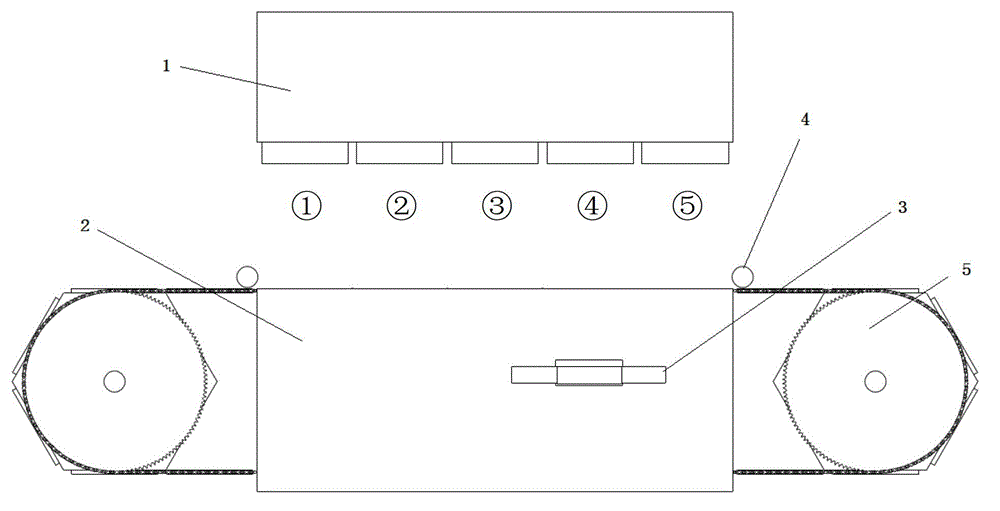

[0045] A fuel cell large-area metal bipolar plate continuous stamping die, including a progressive die composed of 5 stations, station ① is to first punch four positioning pin holes, and then insert the positioning pins through the manipulator, and punch the positioning pin holes The cutting die is set on the slider; station ② is to form the parallel groove of the flow channel with compensation; station ③ is to punch special-shaped holes; station ④ is to trim and blank; station ⑤ is to pull out the positioning pin; After the plate passes through the stations ①, ②, and ③ in sequence, it goes to the station ④ to trim and blank the material to form a bipolar plate, and the station ⑤ takes the scrap after trimming out of the stamping die.

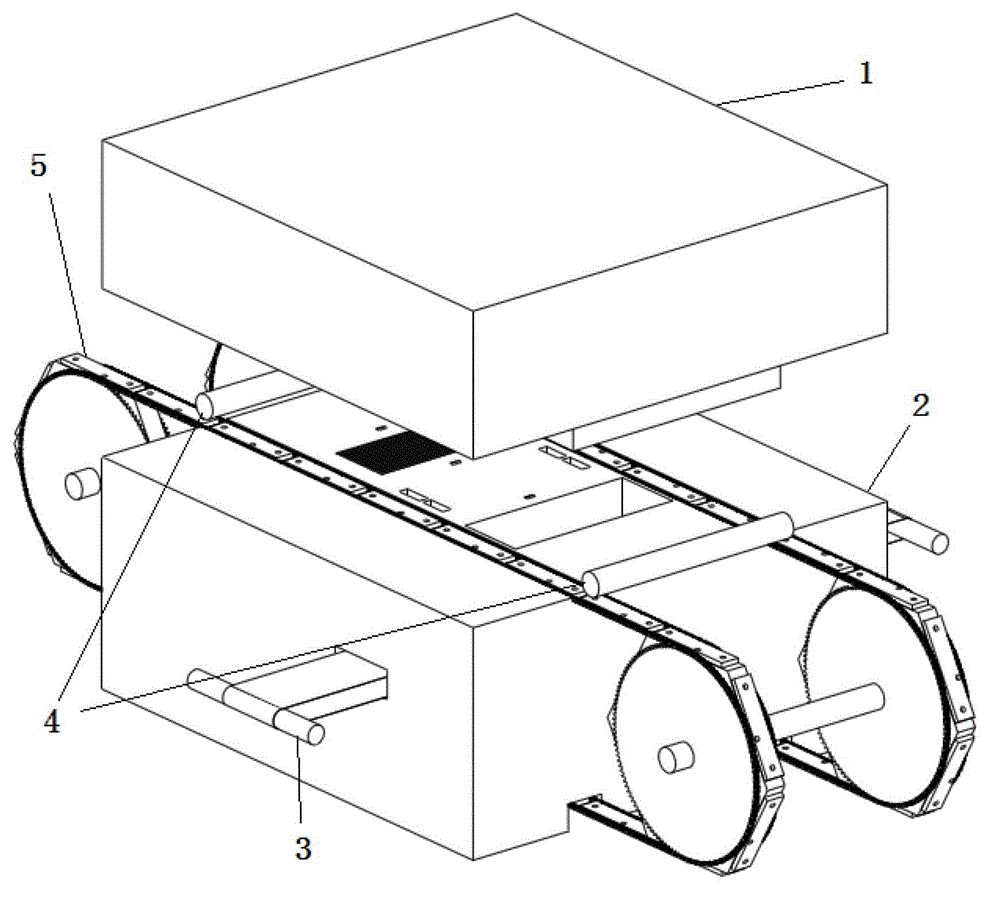

[0046] like Figure 2-Figure 3 As shown, the progressive die includes an upper die 1, a lower die 2, a transmission assembly, a roller 4 and a blanking conveyor belt 3, the upper die 1 is set opposite to the lower die 2, and the transmission as...

Embodiment 2

[0057] This embodiment is implemented under the following conditions of implementation and technical requirements:

[0058] The stamping force is 250 tons, the speed of the sprocket is 3° / sec, and the intermittent time is 10 seconds. The plate material is 316 stainless steel, and the thickness of the material is 0.1mm. The length of the slider is 250mm, the width is 50mm, the distance between the sliders on both sides is 440mm; the width of the material is 500mm, the positioning pin hole is a Φ10 round hole, the positioning pin is a Φ10 cylindrical pin, the distance between the positioning pin holes on the same side is 180mm, and the distance between the positioning pin holes on the opposite side 450mm; the station ⑤ of this embodiment is an empty station, and no manipulator for pulling out the positioning pin is installed.

[0059] The compensation mode of the stamping mold with parallel grooves selected in this embodiment is parabolic compensation with more in the middle and...

Embodiment 3

[0062] This embodiment is implemented under the following conditions of implementation and technical requirements:

[0063] The stamping force is 250 tons, the speed of the sprocket is 10° / sec, and the intermittent time is 20 seconds. The plate material is 316 stainless steel, and the thickness of the material is 0.1mm. The length of the slider is 220mm, the width is 50mm, the distance between the sliders on both sides is 430mm; the width of the material is 500mm, the positioning pin hole is a Φ10 round hole, the positioning pin is a Φ10 cylindrical pin, the distance between the positioning pin holes on the same side is 170mm, and the distance between the positioning pin holes on the opposite side 450mm.

[0064] The compensation method of the stamping die with parallel grooves selected in this embodiment is a parabolic and linear mixed compensation with more in the middle and less at both ends, which is a mixed application form of Embodiment 1 and Embodiment 2. The compensatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com