Rapid subsidence thermoforming mold and thermoforming method of aluminum alloy sections

A technology of aluminum alloy profiles and hot forming, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of low efficiency of production process, difficult heating, low heating efficiency, etc., to improve energy utilization rate and shorten the forming cycle , Heating efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

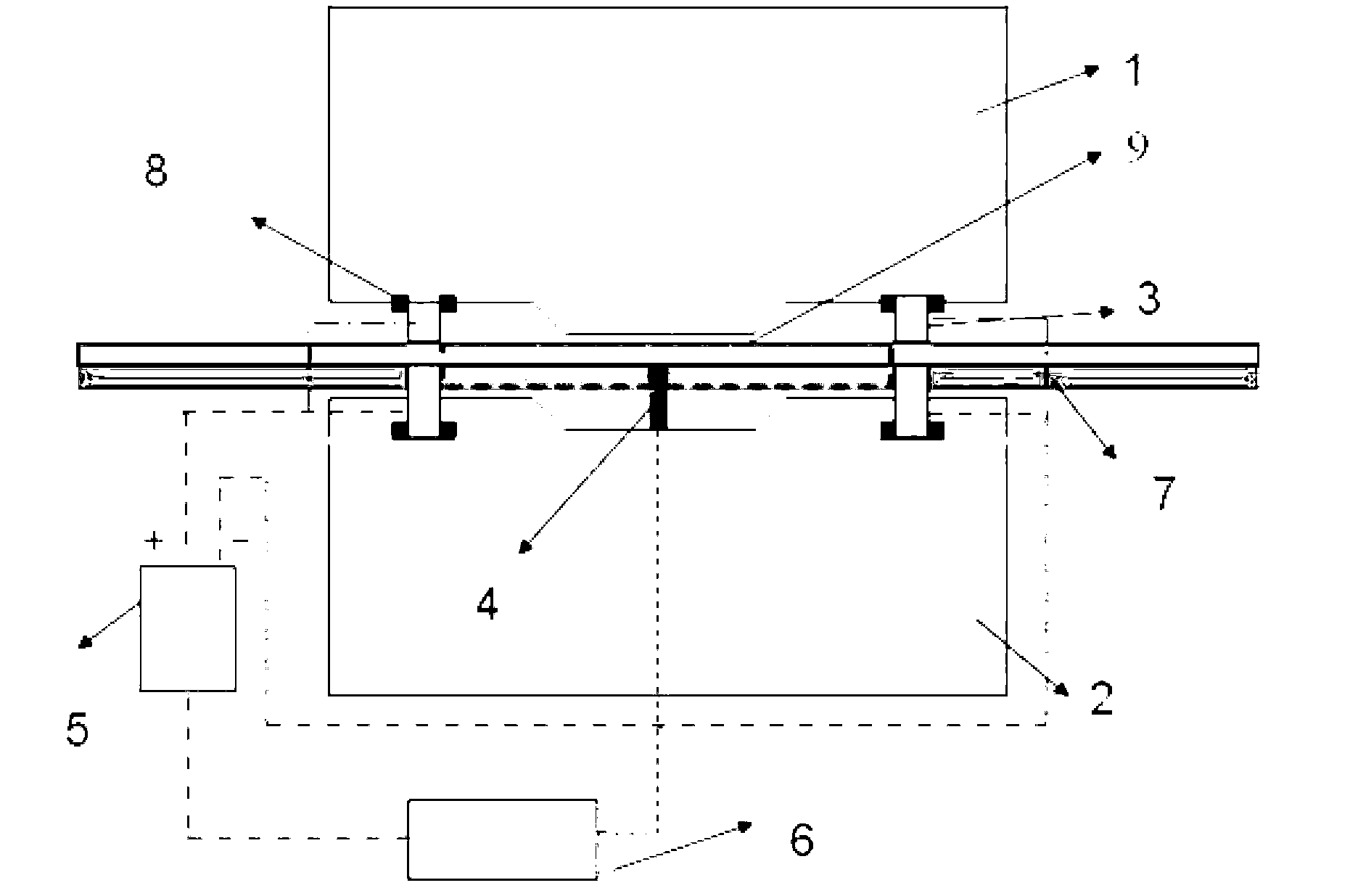

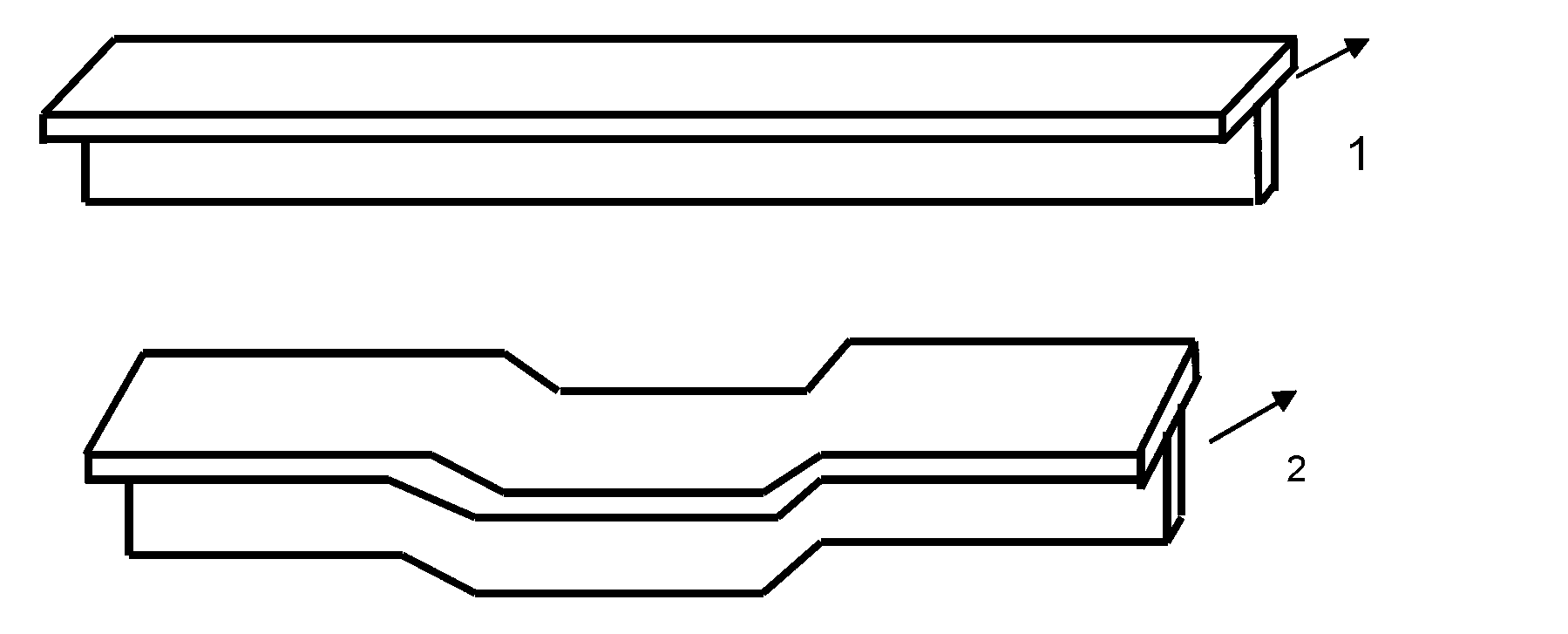

[0018] Embodiment 1: The current-assisted rapid sag thermoforming mold for aluminum alloy profiles in this embodiment includes a punch 1, a die 2, two contact electrodes 3, a contact thermocouple 4, a pulse power supply 5 and a PID control system 6. The middle part of the punch 1 protrudes, and the part of the die 2 corresponding to the protrusion of the middle part of the punch 1 has a depression. One contact electrode 3 is fixed on the die 2 through an insulating structure 8, and the other contact electrode 3 is fixed on the die 2 through the insulating structure 8, and the two contact electrodes 3 are symmetrically arranged relative to the depression, the signal input end of the PID control system 6 is connected to the signal output end of the contact thermocouple 4, and the output end is connected to the pulse power supply 5 The controlled end is to control the output current value, the positive pole and the negative pole of the pulse power supply 5 are respectively connect...

specific Embodiment approach 2

[0021] Embodiment 2: This embodiment differs from Embodiment 1 in that: the punch 1 and the die 2 are T-shaped, Z-shaped, ∟-shaped or I-shaped. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0022] Specific implementation mode three: The rapid sag thermoforming of aluminum alloy profiles in this implementation mode is carried out according to the following steps:

[0023] 1. Put the area to be processed of the profile blank 7 into the processing area 9 of the aluminum alloy profile current-assisted rapid sinking thermoforming mold; 2. Control the contact electrode 3 with a current of 3000-100000A and a voltage of 3-7V through the pulse power supply 5 Under certain conditions, the area to be processed of the profile blank 7 is heated and pressed. During the heating and pressure process, the temperature of the processing area 9 is controlled by the PID control system 6 and the contact thermocouple 4, so that the temperature of the processing area 9 is maintained at 100 ℃~350℃, carry out the mold closing of the concave mold 2 and the convex mold 1 to realize the local deformation of the profile, that is to complete the rapid sag thermoforming of the aluminum alloy pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com