Cold-rolled wire online automatic rebar butt welding device

An automatic, steel bar technology, applied in the field of steel bar cold rolling, can solve the problems of inconvenient butt welding process, affecting cold rolling production line rolling of wire rods, and welding quality not meeting the requirements, achieving simple structure, good welding quality, and saving effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

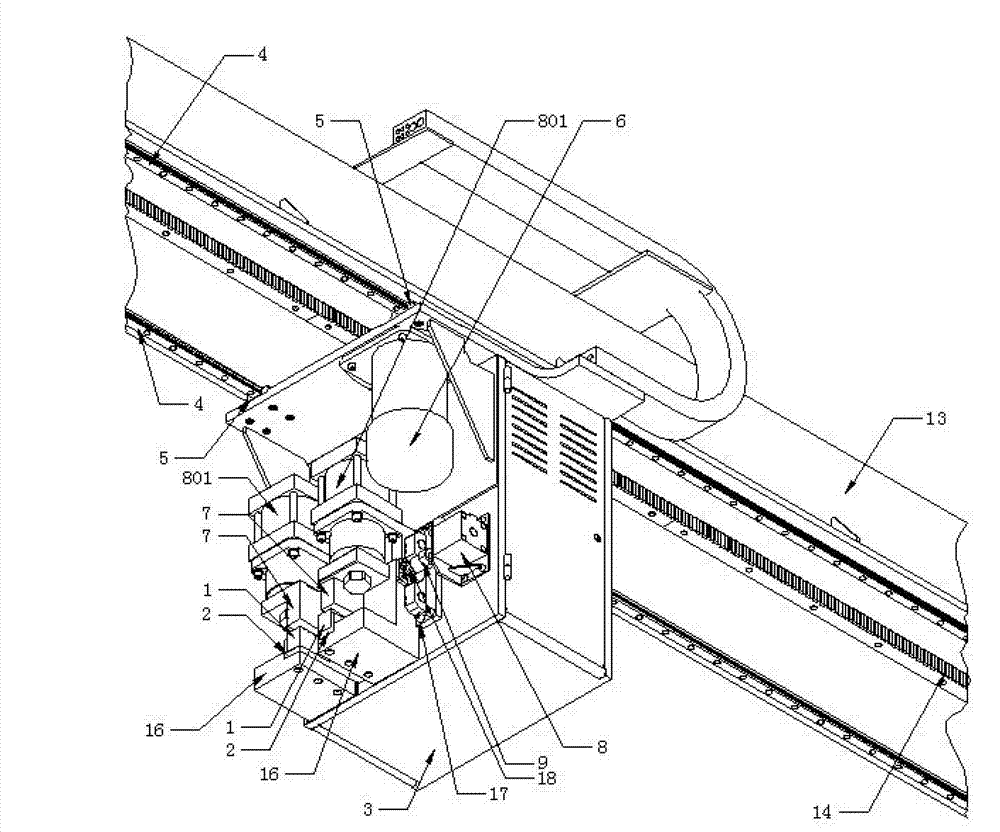

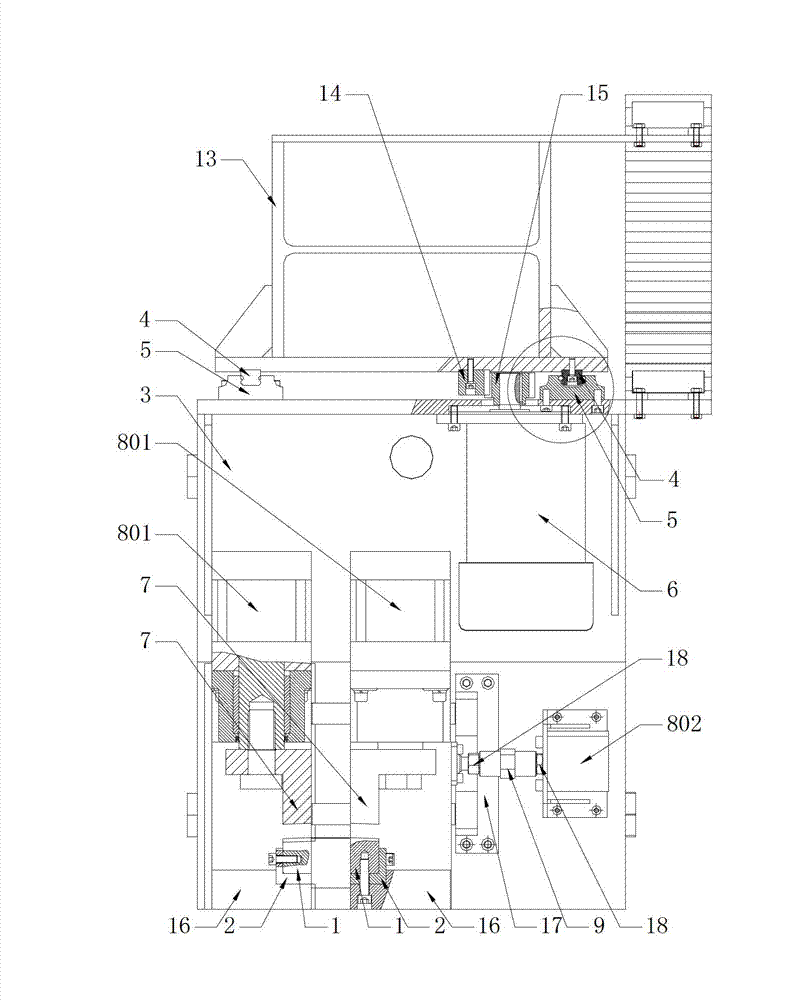

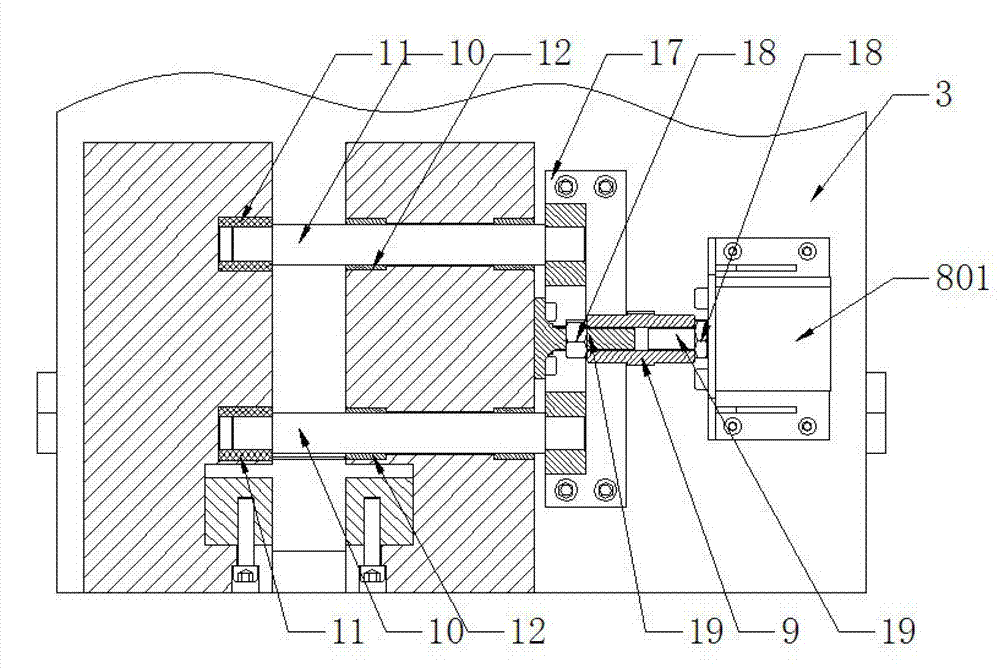

[0021] The present invention will be further described in conjunction with accompanying drawing:

[0022] On-line automatic steel bar butt welding device for cold-rolled wire rods, including a pressing mechanism and an upsetting mechanism installed on the frame, the pressing mechanism includes a fixed end and a moving end, and the moving end is connected with the upsetting mechanism to drive The moving end moves toward or away from the fixed end. combine figure 1 , figure 2 and image 3 As shown, both the fixed end and the moving end are composed of an anvil 1 and a pressing piece above the anvil, and there is an arc-shaped groove on the anvil 1, and the anvil 1 is a chrome-lead-copper electrode, and the arc-shaped groove Multiple grooves with different radians can be used to embed the steel bars to realize accurate positioning and alignment of the ends of the two welded steel bars, and can be matched for different types of steel bars. The chrome-zirconium copper electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com