Floating roll device for film production device

A kind of production equipment and floating roller technology, which is applied in the direction of thin material processing, transportation and packaging, winding strips, etc., can solve the problems of difficult implementation and use, difficult adjustment, complex structure, etc., and achieve simple structure, improved production efficiency, film Roll up smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

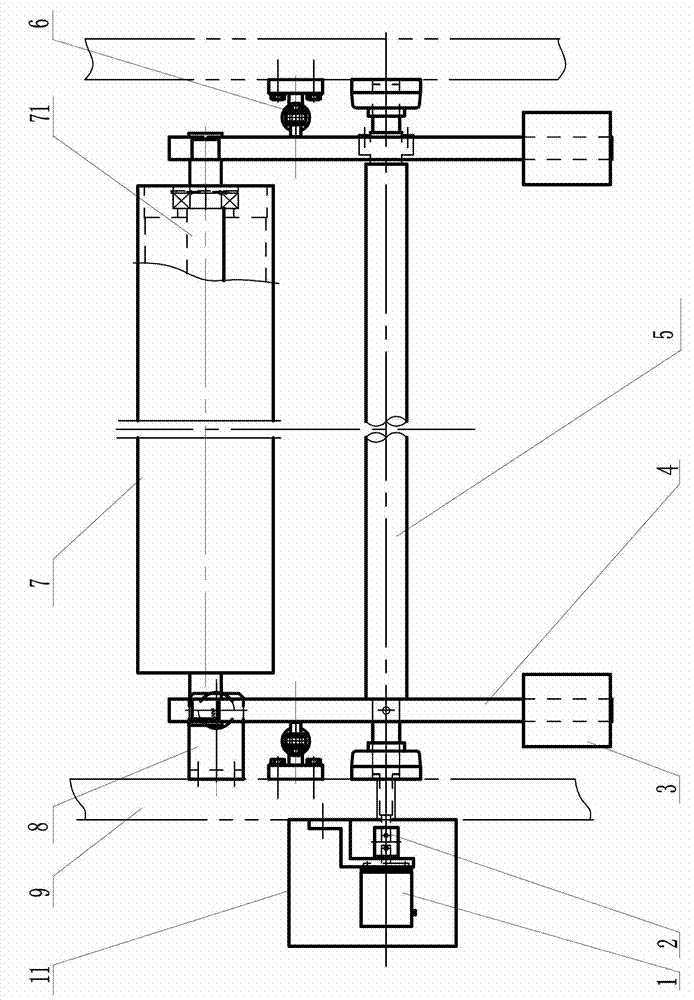

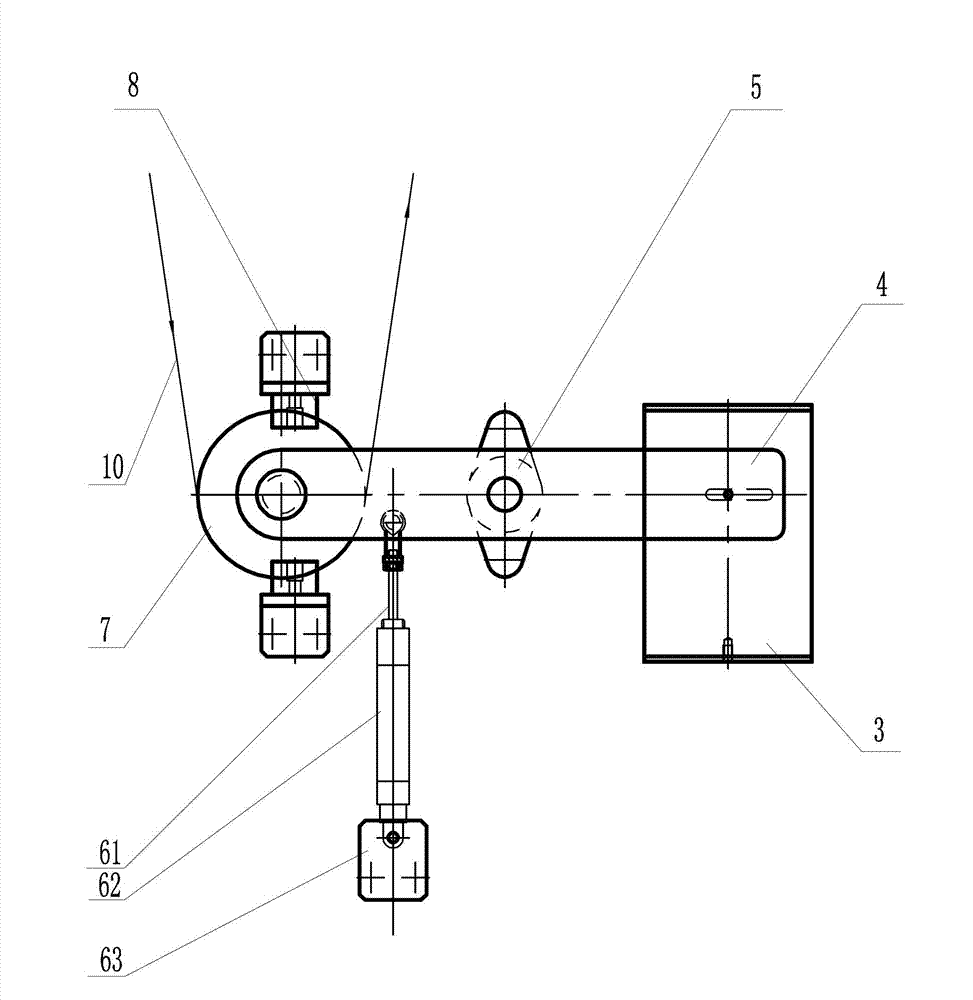

[0026] Examples of the floating roller device of this film production equipment figure 1 and 2 As shown, the floating roller 7 is a hollow roller, and a rolling bearing is embedded at each end of the floating roller. The ring and the roller are fixed as one, and the two ends of the mandrel 71 are fixed in the corresponding holes of the left and right swing arms 4 . The floating roller 7 is lower than the guide roller, and the film 10 goes downward from the front guide roller, bypasses the bottom of the floating roller 7, and is wound up on the reel by the rear guide roller to form a film roll.

[0027] There are steps at both ends of the rotating rod 5, and the left end of the rotating rod 5 passes through the relative hole of the rotating arm 4 on the left side and is fixedly connected with the rotating arm 4 on the left side; the right end of the rotating rod 5 passes through the corresponding hole of the rotating arm 4 on the right side and is connected with The right rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com