Transparent conducting solution and preparation method thereof, color film substrate and manufacturing method

A technology of transparent conduction and production method, which is applied in the direction of conductive materials, conductive materials, conductive coatings, etc., can solve the problem of high production cost, achieve good hardness and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

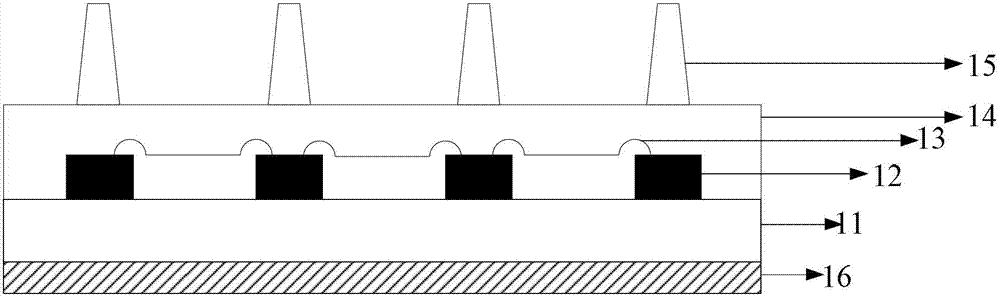

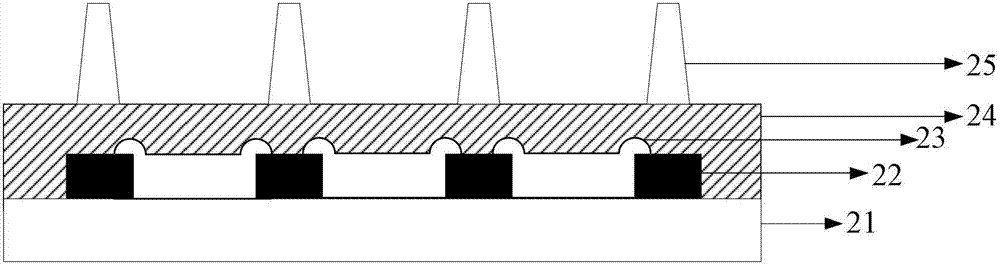

[0030] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them.

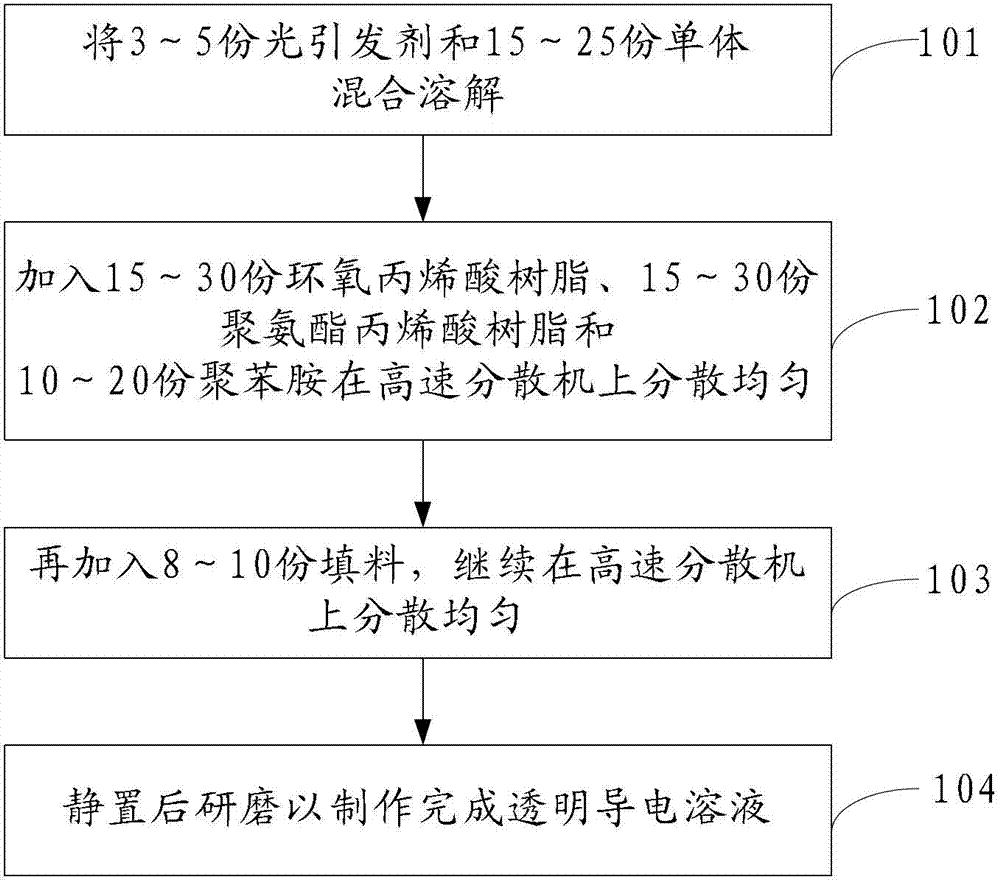

[0031] The embodiment of the present invention provides a transparent conductive solution. According to the weight ratio, the transparent conductive solution includes: 15-30 parts of epoxy acrylic resin, 15-30 parts of polyurethane acrylic resin, 10-20 parts of polyaniline, photoinitiated 3-5 parts of agent, 15-25 parts of monomer, 8-10 parts of filler.

[0032] In the embodiment of the present invention, the main resin used to make the transparent conductive solution is acrylic ester, including epoxy acrylic resin and polyurethane acrylic resin. The polyaniline is a conductive resin, so that the transparent conductive solution has a conductive function. The photoinitiator can initiate the polyme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com