Method and device for generating power through low-temperature waste gas waste in industrial furnace production technology

A production process and waste heat power generation technology, which is used in steam engine installations, machines/engines, mechanical equipment, etc. to reduce operating costs, improve utilization, and achieve significant energy-saving effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

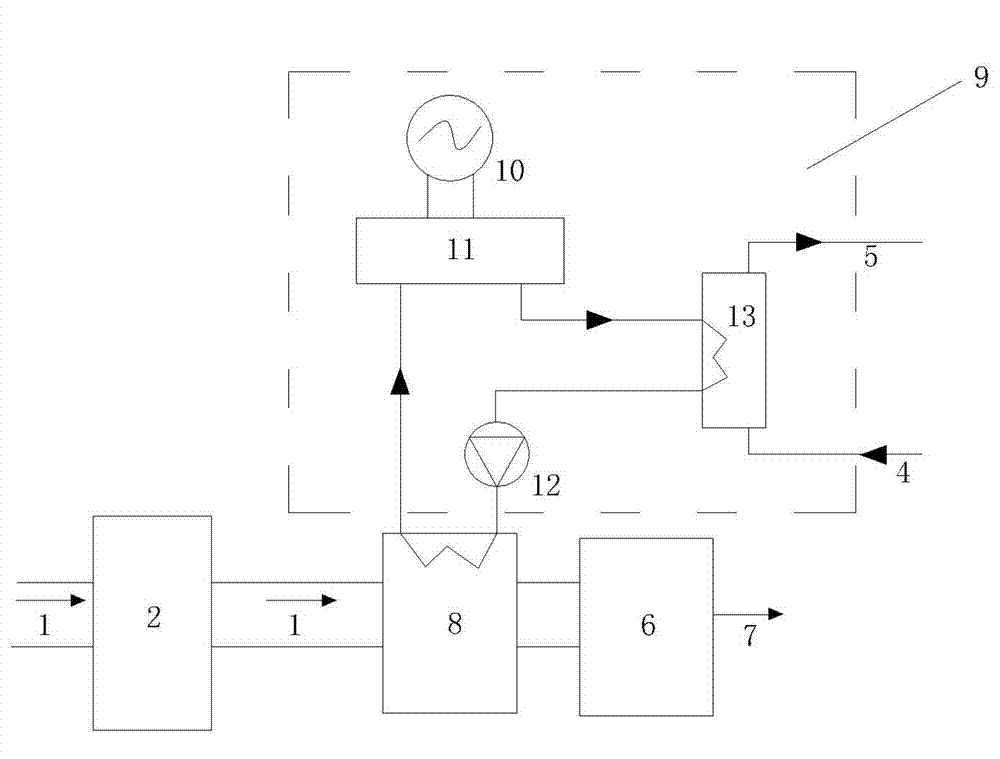

[0014] The device and method of the present invention will be further described below in conjunction with the accompanying drawings.

[0015] Such as figure 1 The shown low-temperature waste gas waste heat power generation device in the industrial kiln production process includes a preliminary industrial kiln waste gas utilization device 2, heat extraction equipment and material recovery or flue gas purification device 6 connected in sequence through the exhaust gas pipeline, and heat extraction equipment 8 Connect with generator set 9 on the top. The generator set 8 is composed of a low-temperature thermal double-cycle generator 10, an expander 11, a heat release device 13 and a high-pressure working medium pump 12, wherein the expander 11, the heat release device 13, the high-pressure working medium pump 12 and the heat extraction device 8 are jointly formed The circulation circuit for the flow of power generation medium, the output end of the heat extraction device 8 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com