Heat source working hot air engine

A hot gas engine and work technology, which is applied in hot gas variable capacity engine installations, closed gas positive displacement engine plants, mechanical equipment, etc., can solve problems such as affecting the efficiency of Stirling engines, low compression ratio, and affecting the scope of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

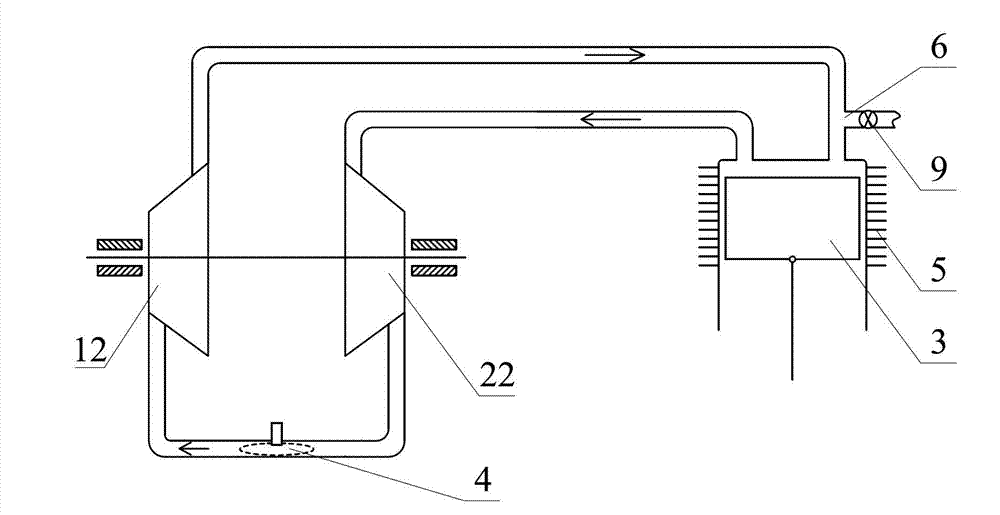

[0086] Such as figure 1 The shown heat source work heat engine includes a gas work mechanism, a gas compression mechanism, a cylinder-piston mechanism 3, an internal combustion combustion chamber 4, a working medium outlet 6 and a cooler 5, the gas work mechanism, the gas compression mechanism, the The cylinder-piston mechanism 3 is connected to form a working medium closed circuit through a communication channel, the gas working mechanism is set as a turbine power mechanism 12, and the gas compression mechanism is set as an impeller compressor 22, and the turbine power mechanism 12 and the impeller compressor The engine 22 is arranged coaxially and outputs power to the impeller compressor 22. The turbine power mechanism 12, the cylinder-piston mechanism 3 and the impeller compressor 22 are connected in turn through a communication channel, and the cooler 5 is arranged on the On the cylinder of the cylinder-piston mechanism 3, the internal combustion combustion chamber 4 is a...

Embodiment 2

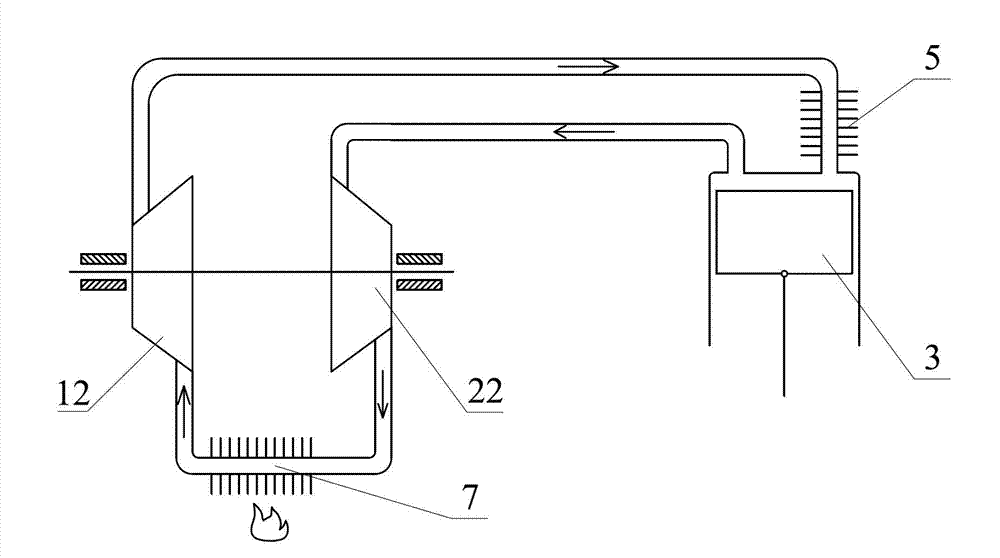

[0091] Such as figure 2 The shown heat source working heat engine includes a gas working mechanism, a gas compression mechanism, a cylinder-piston mechanism 3, a heater 7 and a cooler 5; The working medium inlet is connected, the working medium outlet of the cylinder-piston mechanism 3 is connected with the working medium inlet of the gas compression mechanism through the communication channel, and the working medium outlet of the gas compression mechanism is connected with the working medium of the gas work mechanism through the communication channel. The inlet of the substance is connected to form a closed circuit of the working medium; the gas working mechanism is set as a turbine power mechanism 12, and the gas compression mechanism is set as an impeller compressor 22, and the turbine power mechanism 12 and the impeller compressor 22 are coaxially arranged And output power to the impeller compressor 22, the cooler 5 is arranged on the communication channel between the wor...

Embodiment 3

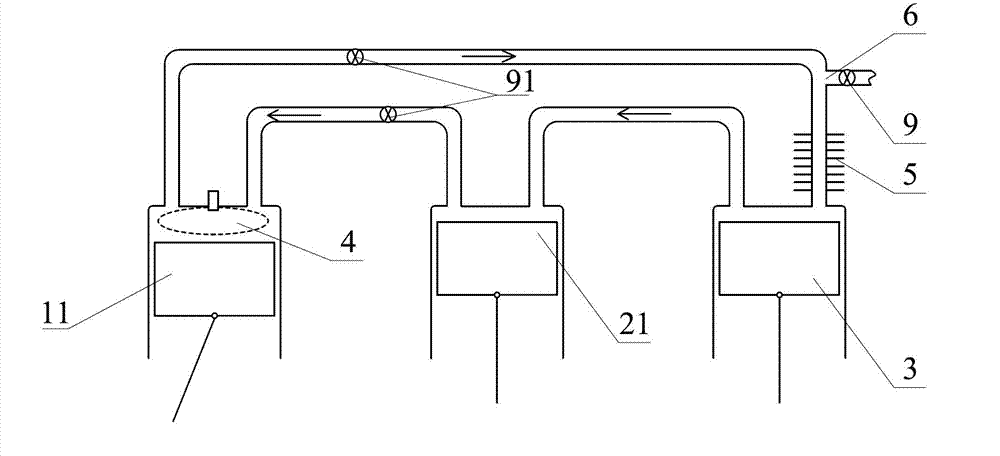

[0094] Such as image 3 The difference between the shown heat source work heater and Embodiment 1 is that the gas work mechanism is changed to a piston type gas work mechanism 11, the gas compression mechanism is changed to a piston type gas compression mechanism 21, and the internal combustion The combustion chamber 4 is relocated in the cylinder of the piston type gas work mechanism 11, and the cooler 5 is relocated on the communication channel between the working medium outlet 6 and the working medium inlet of the cylinder-piston mechanism 3, A timing control valve 91 is set on the communication passage between the working medium outlet of the piston type gas working mechanism 11 and the working medium inlet of the cylinder-piston mechanism 3, and a timing control valve 91 is set at the working medium outlet of the piston type gas compression mechanism 21. Another timing control valve 91 is provided on the communicating channel with the working medium inlet of the piston ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com