Equipment and process method for manufacturing EL luminous signboards by water-flowing type array jet printing

A flow-type, signage technology, applied to illuminated signs, instruments, display devices, etc., can solve the problem that the effect cannot meet the process requirements, and achieve the effects of environmental protection, rich colors and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

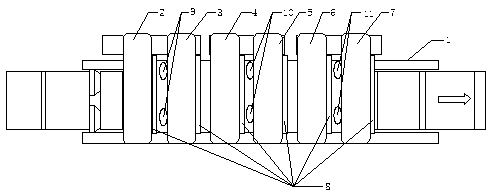

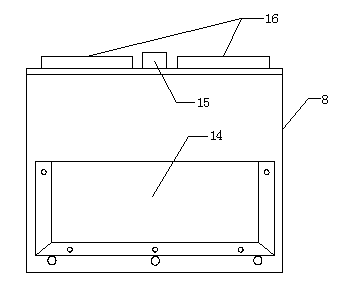

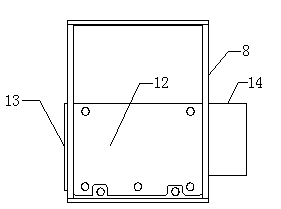

[0033] Such as figure 1 As shown, the equipment for producing EL light-emitting signs by flow-type array jet printing in this embodiment includes a belt conveying platform mechanism 1, a first group of jet printing nozzle arrays 2, a second group of jet printing nozzle arrays 3, and a third group of jet printing nozzle arrays 4. There are UV LED devices 8 behind the 4th group of jet printing nozzle array 5, the 5th group of jet printing nozzle array 6 and the 6th group of jet printing nozzle array 7; the second group of jet printing nozzle array 3, the The front of the 4 groups of jet printing nozzle arrays 5 and the 2nd group of jet printing nozzle arrays 7 are respectively provided with the first group of positioning cameras 9, the second group of positioning cameras 10 and the third group of positioning cameras 11; the first group of jet printing nozzles Array 2, the second group of jet printing head array 3, the third group of jet printing head array 4, the fourth group of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap