Micro-surfacing mixing material doped with rock asphalt and preparation method thereof

A technology of micro-surfacing mixture and rock asphalt, which is applied in the field of pavement micro-surfacing materials, can solve problems such as surface functional diseases, and achieve the effects of enhanced water damage resistance, increased durability, and good water sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

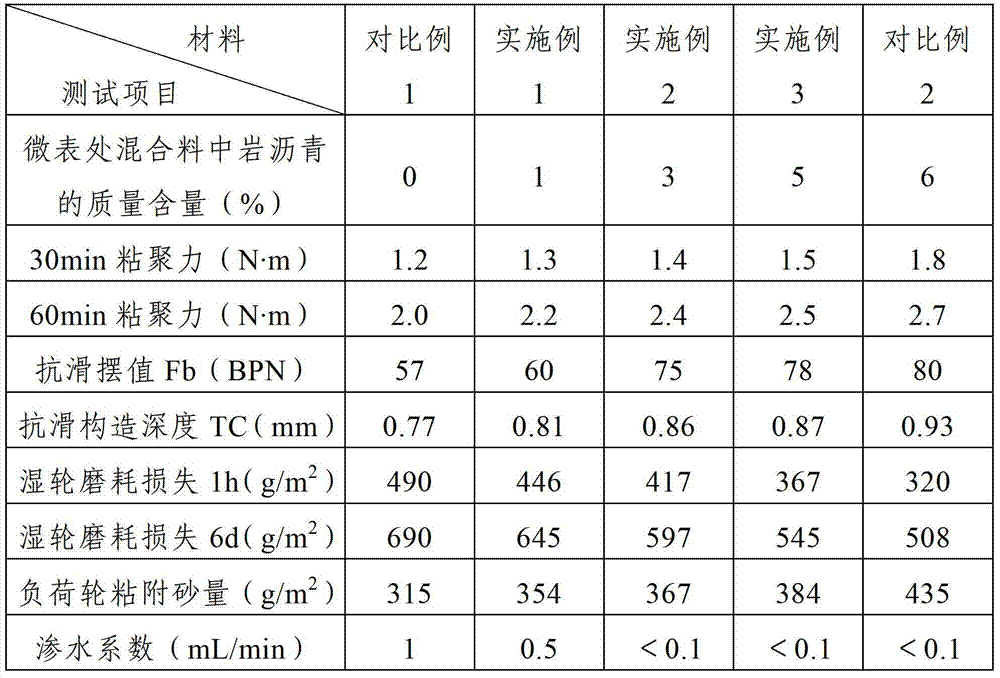

[0027] In this embodiment, the micro-surface mixture mixed with rock asphalt is made of the following raw materials in mass percentage: 76.8% of aggregate, 5% of mineral powder, 1.2% of cement, 1% of rock asphalt, 8% of water, and 8% of modified asphalt , the modified asphalt is SBR modified emulsified asphalt;

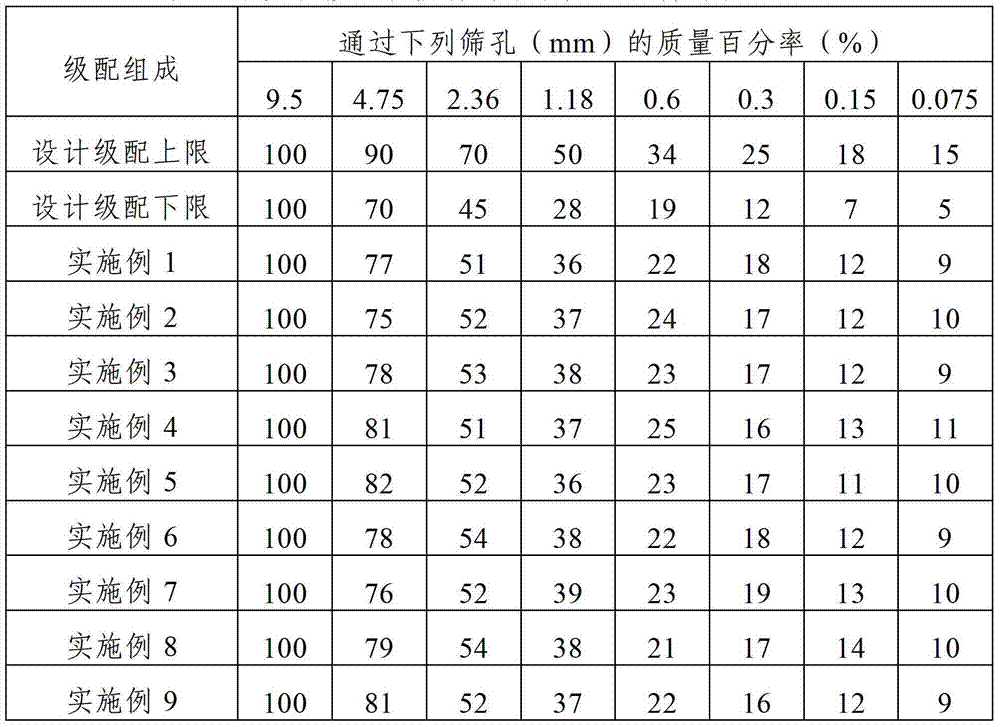

[0028] The aggregate, mineral powder, cement and SBR modified emulsified asphalt all meet the relevant technical requirements of the Ministry of Communications Ministry of Communications standard JTG F40-2004 "Technical Specifications for Construction of Highway Asphalt Pavement". The gradation type of the mixture is MS-3 type, and the specific gradation composition is shown in Table 1;

[0029] In the present embodiment, rock asphalt is preferably Indonesian Buton rock asphalt with asphalt mass content of 25%; SBR modified emulsified asphalt is preferably composed of base asphalt, SBR latex modifier, cationic asphalt emulsifier and water in a mass ratio of 64: 4:2:3...

Embodiment 2

[0036] In this embodiment, the micro-surface mixture mixed with rock asphalt is made of the following raw materials in mass percentage: 74.8% aggregate, 5% mineral powder, 1.2% cement, 3% rock asphalt, 8% water, and 8% modified asphalt , the modified asphalt is SBR modified emulsified asphalt;

[0037] The aggregate, mineral powder, cement and SBR modified emulsified asphalt all meet the relevant technical requirements of the Ministry of Communications Ministry of Communications standard JTG F40-2004 "Technical Specifications for Construction of Highway Asphalt Pavement". The gradation type of the mixture is MS-3 type, and the specific gradation composition is shown in Table 1;

[0038] In this embodiment, rock asphalt is preferably Indonesian Buton rock asphalt with a mass content of 25% asphalt; SBR modified emulsified asphalt is preferably composed of base asphalt, SBR latex, cationic asphalt emulsifier and water in a mass ratio of 64:4:2 : 30 mixed evenly; among them, the...

Embodiment 3

[0045] In this embodiment, the micro-surface mixture mixed with rock asphalt is made of the following raw materials in mass percentage: 72.8% of aggregate, 5% of mineral powder, 1.2% of cement, 5% of rock asphalt, 8% of water, and 8% of modified asphalt , the modified asphalt is SBR modified emulsified asphalt;

[0046] The aggregate, mineral powder, cement and SBR modified emulsified asphalt all meet the relevant technical requirements of the Ministry of Communications Ministry of Communications standard JTG F40-2004 "Technical Specifications for Construction of Highway Asphalt Pavement". The gradation type of the mixture is MS-3 type, and the specific gradation composition is shown in Table 1;

[0047] In the present embodiment, rock asphalt is preferably Indonesian Buton rock asphalt with asphalt mass content of 25%; SBR modified emulsified asphalt is preferably composed of base asphalt, SBR latex modifier, cationic asphalt emulsifier and water in a mass ratio of 64: 4:2:3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com