Steel ball conveyor

A steel ball conveyor and conveying box technology, applied in furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve the problems of ineffective conveying devices, technical difficulties, large height differences, etc., and achieve the effect of reasonable structure and reliable transmission coordination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

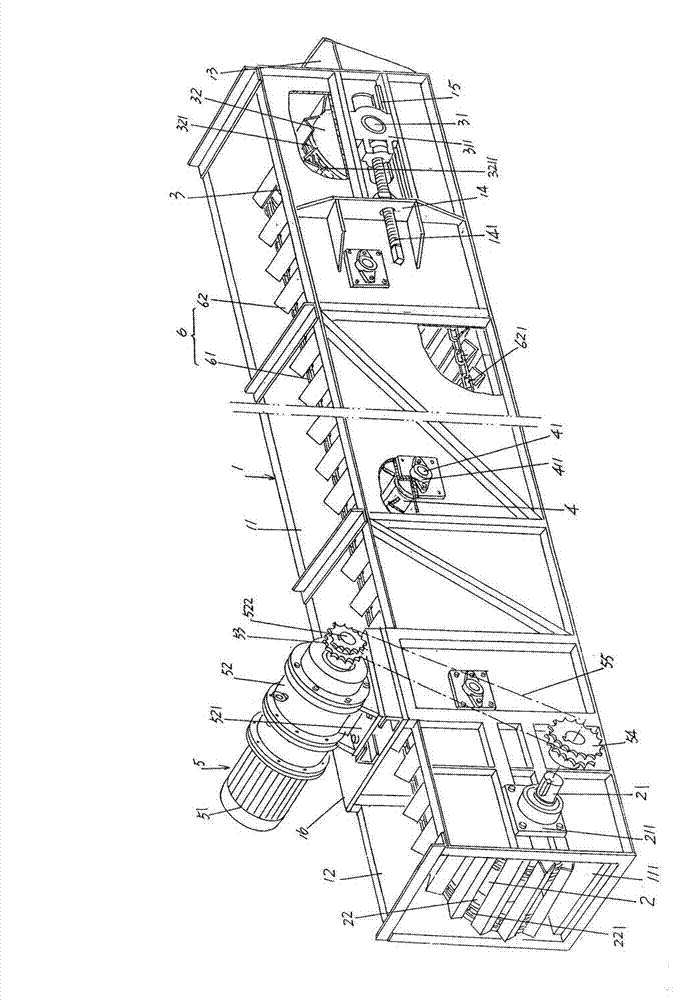

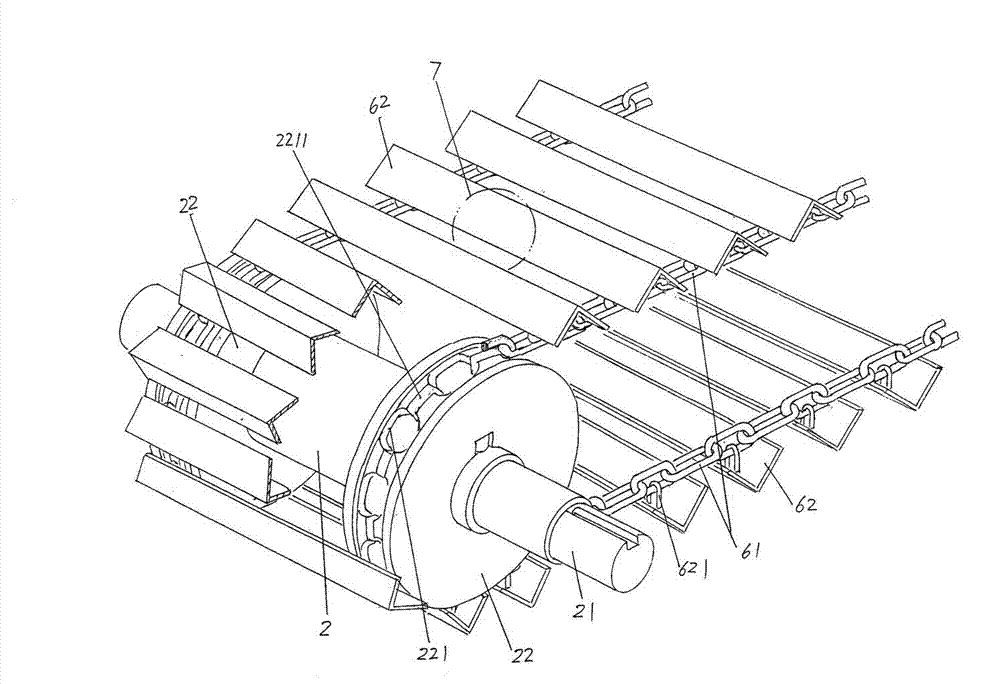

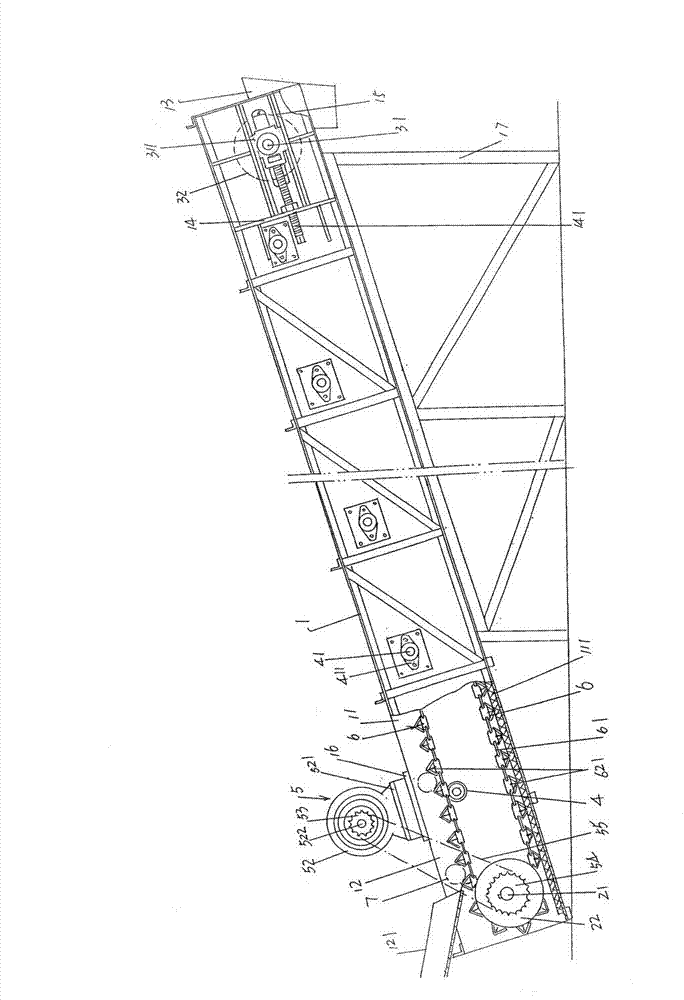

[0015] See figure 1 and figure 2 ,exist figure 1 Among them, a delivery box 1 is provided, the upper part of the longitudinal direction of the delivery box 1 is preferably not closed, and the upper part of one end of the delivery box 1 is formed as a ball entry port 12, and the ball entry port 12 is equipped with Set guide ball groove 121 ( image 3 shown) the quenched steel ball 7 from the quenching mechanism ( image 3 Shown) introduce the steel ball carrying mechanism 6 that also will be described in detail below. A ball unloading bucket 13 is configured at the end face position of the other end of the delivery box 1, and a wear-resistant plate 111 is laid on the bottom of the delivery box cavity 11 of the delivery box 1. The wear-resistant plate 111 preferably uses stone, that is, uses a stone slab.

[0016] A main drive roller 2 is provided, and one end of the main drive roller 2 and the main drive roller shaft head 21 at the other end are rotatably supported on one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com