Wear-resistant cast steel bucket tooth and production method thereof

A technology of cast steel and bucket teeth, which is applied in the field of wear-resistant steel, can solve the problems of high cost, achieve the effects of low production cost, simple preparation method, and improved wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

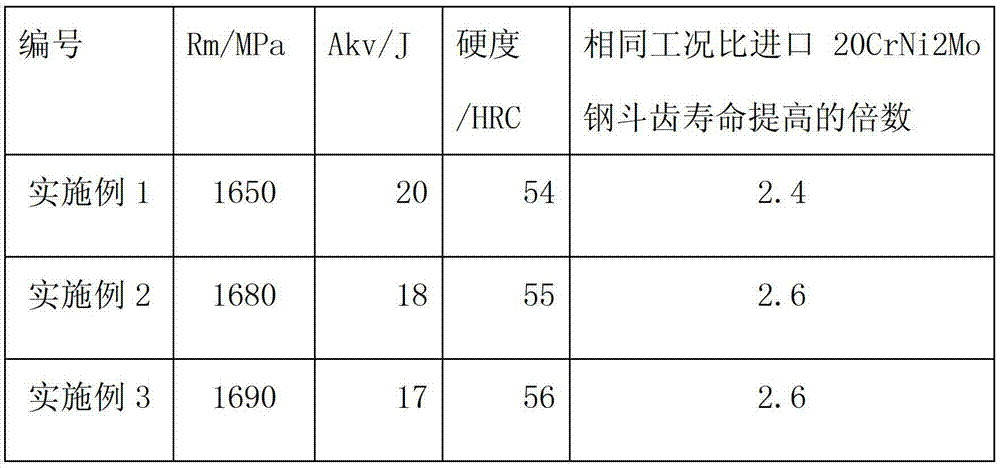

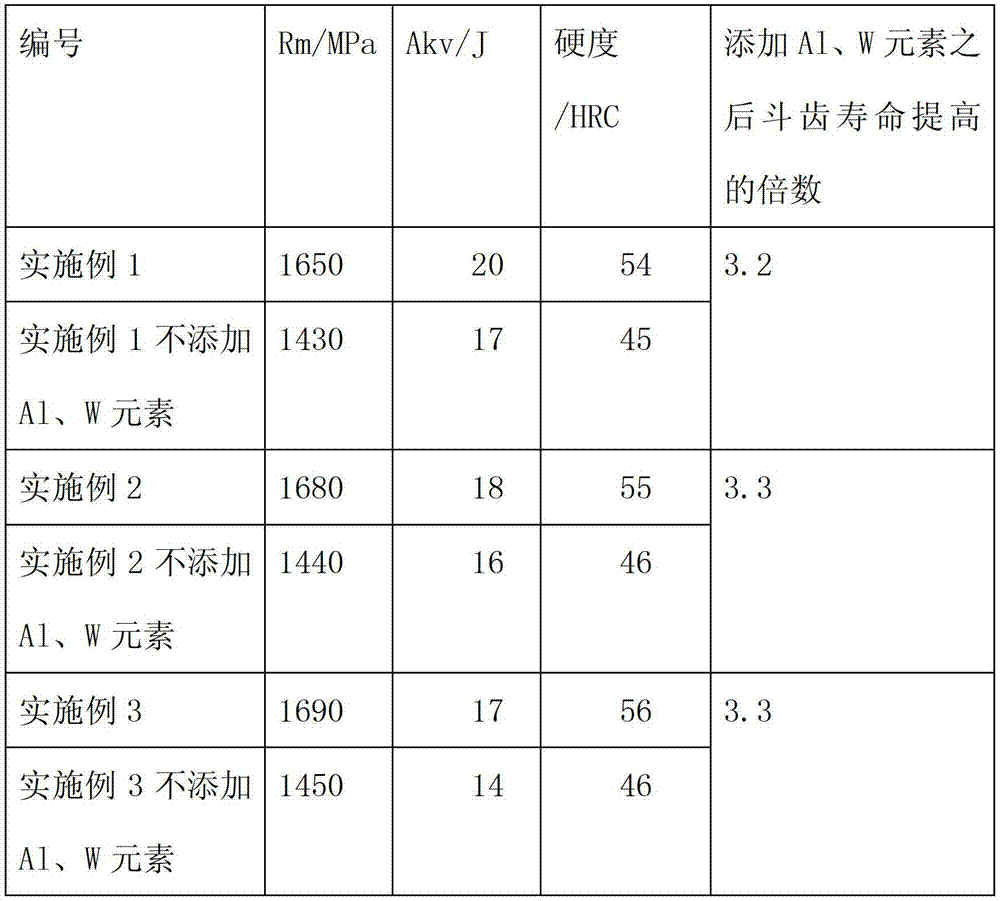

Embodiment 1

[0026] A wear-resistant cast steel bucket tooth consists of the following components in weight percentage:

[0027] C: 0.9%, Ti: 0.25%, Al: 0.12%, Mo: 2%, W: 3%, P: 0.02%, S: 0.008%, and the balance is Fe; The preparation method is carried out according to the following procedures:

[0028] 1) In terms of weight percentage, the composition is: C: 0.9%, Ti: 0.25%, Al: 0.12%, Mo: 2%, W: 3%, P: 0.02%, S: 0.008%, and the balance is Fe The molten steel is desulfurized, combined blowing on the top and bottom of the converter, RH vacuum degassing treatment, and the molten steel is released when the temperature of the molten steel is 1660°C;

[0029] 2) Cast steel bucket teeth with the desired shape in the wax mold shell with a preheating temperature of 450°C, and control the cooling time of the cast steel bucket teeth to 1550°C within 10 minutes;

[0030] 3) When the temperature of the cast steel bucket tooth is lowered to 1250°C, keep it warm for 2 hours to fully disperse and prec...

Embodiment 2

[0033] A wear-resistant cast steel bucket tooth consists of the following components in weight percentage:

[0034] C: 1.1%, Ti: 0.22%, Al: 0.1%, Mo: 2.6%, W: 4%, P: 0.012%, S: 0.009%, and the balance is Fe; The preparation method is carried out according to the following procedures:

[0035] 1) In terms of weight percentage, the composition is: C: 1.1%, Ti: 0.22%, Al: 0.1%, Mo: 2.6%, W: 4%, P: 0.012%, S: 0.009%, and the balance is Fe The molten steel is desulfurized, combined blowing at the top and bottom of the converter, RH vacuum degassing treatment, and the molten steel is released when the temperature of the molten steel is 1680°C;

[0036] 2) Cast steel bucket teeth with the desired shape in the wax mold shell with a preheating temperature of 480°C, and control the cooling time of the cast steel bucket teeth to 1550°C within 13 minutes;

[0037] 3) When the temperature of the cast steel bucket tooth is lowered to 1260°C, keep it warm for 1.5 hours to fully disperse an...

Embodiment 3

[0040] A wear-resistant cast steel bucket tooth consists of the following components in weight percentage:

[0041] C: 1.2%, Ti: 0.2%, Al: 0.08%, Mo: 3%, W: 5%, P: 0.011%, S: 0.02%, and the balance is Fe; The preparation method is carried out according to the following procedures:

[0042] 1) In terms of weight percentage, the composition is: C: 1.2%, Ti: 0.2%, Al: 0.08%, Mo: 3%, W: 5%, P: 0.011%, S: 0.02%, and the balance is Fe The molten steel is desulfurized, combined blowing at the top and bottom of the converter, RH vacuum degassing treatment, and the molten steel is released when the temperature of the molten steel is 1700°C;

[0043] 2) Cast steel bucket teeth with the desired shape in the wax mold shell with a preheating temperature of 500°C, and control the cooling time of the cast steel bucket teeth to 1550°C within 15 minutes;

[0044] 3) When the temperature of the cast steel bucket tooth is lowered to 1280°C, keep it warm for 1 hour to fully disperse and precipi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com