Steel plate with great heat and abrasion resistance and manufacturing method thereof

A technology of wear-resistant steel plate and manufacturing method, which is applied in the field of wear-resistant steel, can solve the problems of reducing the service life of equipment, reducing mechanical properties and wear-resistant performance, and achieve the goals of improving wear-resistant performance, improving strength and hardness, and good machining performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

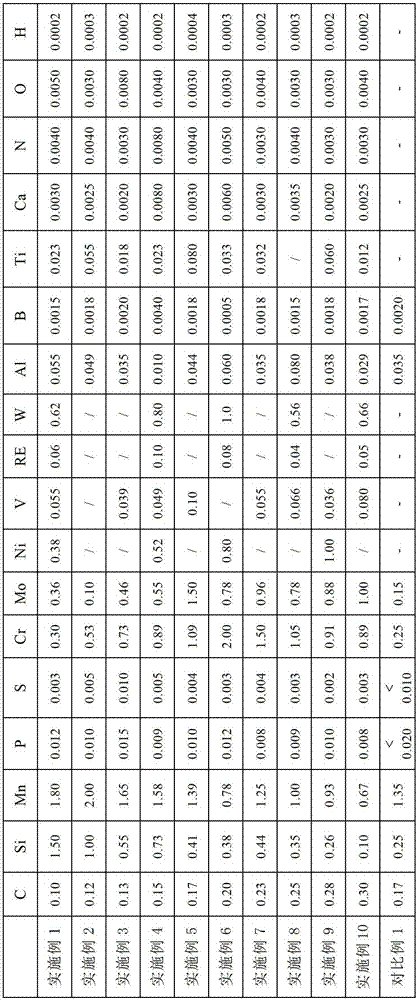

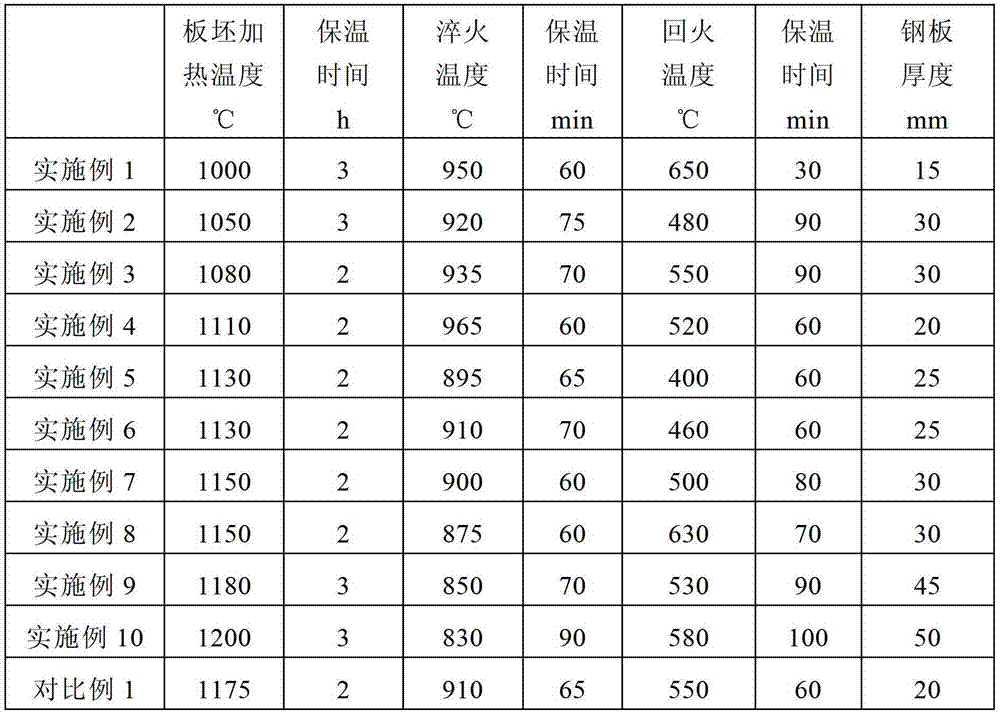

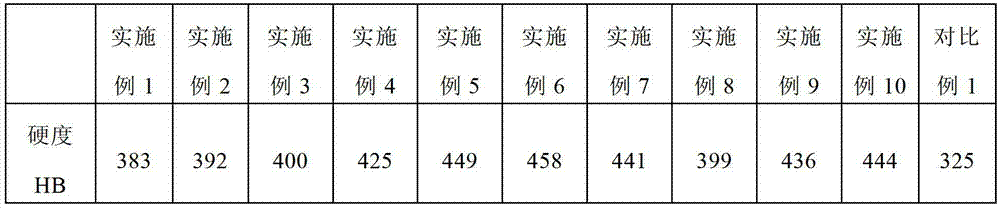

[0038] The heat-resistant and wear-resistant steel plates of the following Examples 1-10 and the steel plates of Comparative Example 1, and the weight percentages of their chemical components are shown in Table 1. The manufacture of the heat-resistant and wear-resistant steel plates of Examples 1-10 and the steel plates of Comparative Example 1 The method is: the corresponding smelting raw materials are sequentially carried out according to the following steps: smelting→casting→heating→rolling→quenching→tempering, controlling the mass percentage ratio of chemical elements of the steel plate in each embodiment and comparative example 1, in the heating step , The heating temperature is 1000-1250°C; in the rolling step, free rolling is used, and air cooling after rolling; in the quenching step, the quenching temperature is 800-980°C, and the holding time is 60-120min; in the tempering step, The tempering temperature is 400-650℃, and the holding time is 30-100min; the specific proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com