Abrasion resisting coating with high gamma-TiAl phase content and preparing method of abrasion resisting coating

A phase content, wear-resistant technology, applied in the direction of coating, metal material coating process, melt spraying, etc., can solve the problem of difficult to prepare coatings, to avoid changes, excellent mechanical properties and wear resistance, low Effect of oxygen/nitrogen impurity phase content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0016] The wear-resistant coating with high γ-TiAl phase content in this embodiment is composed of 45 at% of Al, 5 at% of Nb, 5 at% of V and the balance of Ti (hereinafter abbreviated as Ti-45Al-5Nb-5V) .

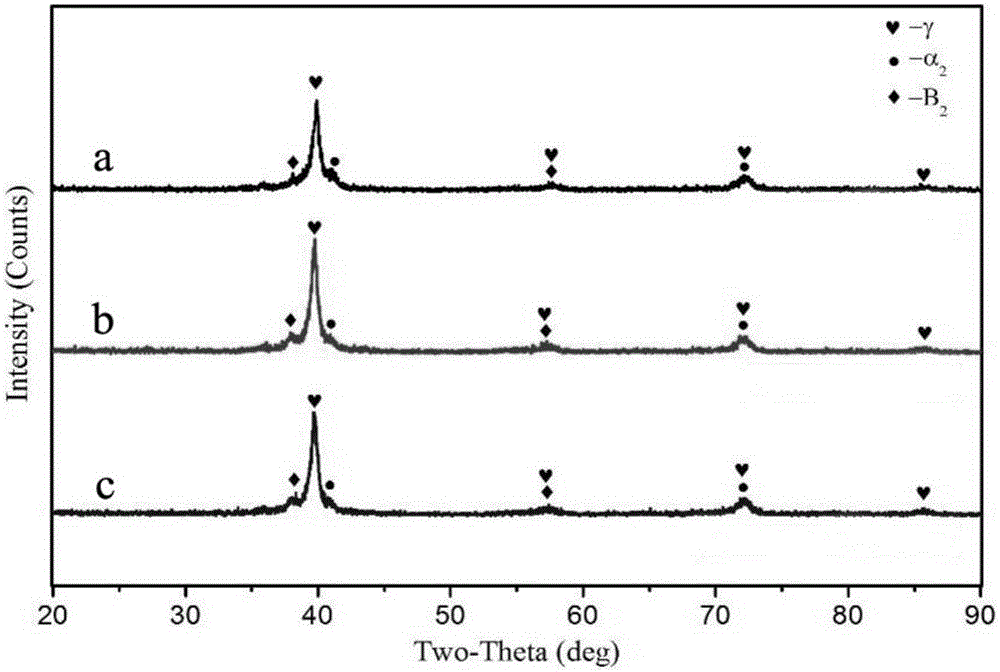

[0017] The phase composition of the coating is as follows: γ-TiAl phase content is 78.7wt%, α 2 -Ti 3 The content of Al phase is 14.2wt%, the content of β-Ti phase is 7.1wt%, and there is no obvious oxygen / nitrogen impurity phase.

[0018] The preparation method of the wear-resistant coating with high γ-TiAl phase content of the present embodiment is as follows:

[0019] ① According to the above atomic percentages, the master alloy AlNb, AlV, Al particles and Ti rods with a purity of ≥ 99.9% are mixed and then added to the vacuum arc melting furnace to be smelted into bulk materials, and then the above bulk materials are prepared by gas atomization pulverizing equipment. A powder material is prepared, and a spray powder with a particle size of 15-40 μm is obtained by sie...

Embodiment 2

[0023] The coating compositions of Examples 2 and 3 are shown in Table 1, and the preparation methods thereof are basically the same as those of Example 1, and the differences are shown in Table 1.

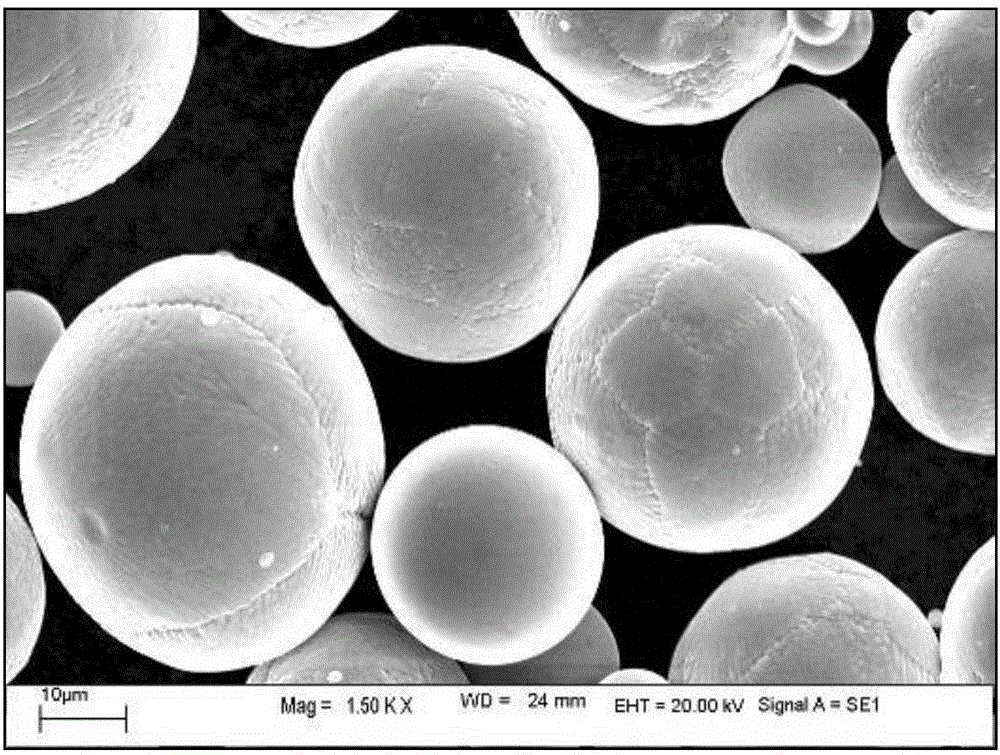

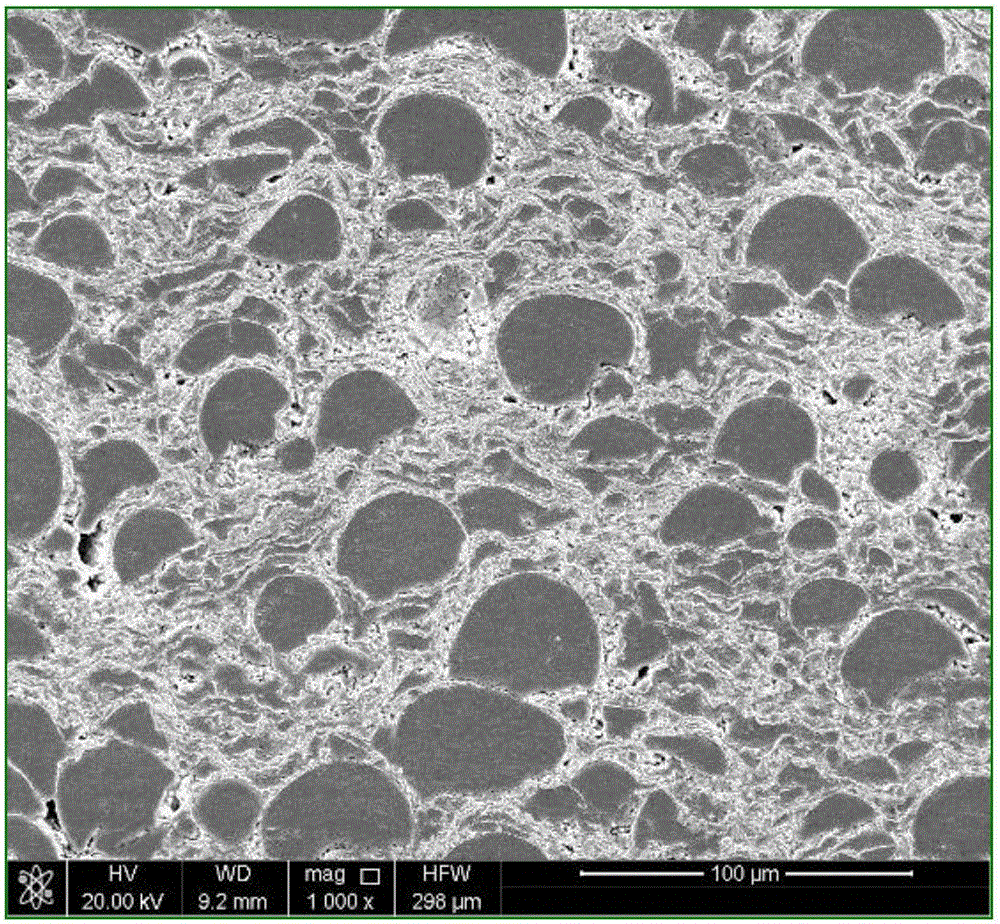

[0024] Wherein, the scanning electron microscope (SEM) diagram of the sprayed powder of Example 3 is shown in figure 1 , the schematic diagram of the cross-sectional micro-morphology of the coating prepared in Example 3 is shown in figure 2 .

[0025] Table 1

[0026]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com