Mask plate with easily removed assistant pattern and production method thereof

An auxiliary pattern and mask technology, applied in the direction of ion implantation plating, coating, electrolysis process, etc., can solve the problems of high peeling quality, uneven outer frame of the mask, unsightly appearance, etc., to achieve neat and smooth edges without burrs , the effect of peeling high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

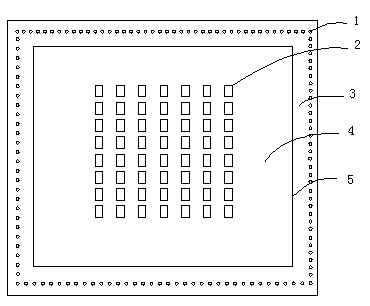

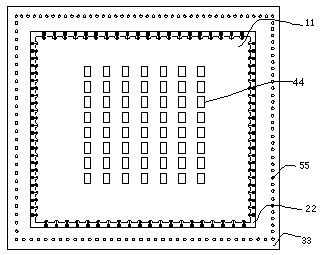

[0037] figure 2 The shown mask plate for the evaporation process includes: the main pattern area 11, the main pattern area has an opening 44 that meets the requirements of evaporation, and the size of the opening of the main pattern is in the range of 30-180 μm; the auxiliary pattern area 33 is used for The point of application of tension is provided; the spacer band 22 is connected to the main figure area 11 and the auxiliary figure 33 on one side. The thickness of the mask plate for evaporation is 10-200 μm. It is preferable that the thickness of the mask plate for vapor deposition is 10 micrometers or more and less than 30 micrometers.

[0038] image 3 The shown edge of the interval band 22 connecting the main graphic area 11 is composed of at least one half-moon line segment 111 indented to the main graphic area and at least one horizontal line segment 222; the edge of the interval band connecting the auxiliary graphic area 33 is a horizontal line segment.

[0039] Th...

Embodiment 2

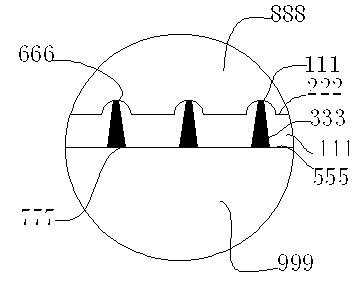

[0042] Figure 4 The shown edge of the interval band 22 connecting the main graphic area 11 is composed of at least one concave line segment 112 indented to the main graphic area and at least one horizontal line segment 222; the edge of the interval band connecting the auxiliary graphic area 33 is a horizontal line segment. The interval band 22 is composed of at least one connecting solid bridge 333 and at least one hollow figure 444, wherein the connecting solid bridge connects the main graphic area 11 and the auxiliary graphic area 33, and the spacer band 22 is hollowed out 444 except for connecting the solid bridge 333; The plane of the connecting solid bridge is trapezoidal, and the length of the upper base 666 is shorter than that of the lower base 777 . The upper bottom of the trapezoidal connecting real bridge is connected with the main graphic area, and the lower bottom is connected with the auxiliary graphic area. The upper base 666 of the trapezoidal connecting soli...

Embodiment 3

[0044] The mask plate is manufactured by using a single-side etching process, and the hollow pattern of the interval band is formed on the mask plate.

[0045] The 20-80μm thick Invar alloy plate is pre-treated, the etched surface is sandblasted to remove impurities on the plate surface, and the dry film adhesion is improved; then the dry film is applied on the front and back sides; the exposed area on the etched surface is as follows: figure 2 The non-dark area of the middle isolation zone 22 and other areas except the opening; peel off the transparent polymer protective film on the surface of the dry film on the etched surface, develop it, and remove the unexposed film. Develop clear. The developed plate is etched: the etching pressure is 20±1psi; the etching speed is 10-60Hz; the specific gravity of the ferric chloride etching solution is 1.00-1.50 g / cm 3; After the etching stage is completed, the non-exposed area is etched through, the film is faded, and the hollow are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com