A metal mask for vapor plating and a production method thereof

A metal mask and its technology are applied in vacuum evaporation plating, metal material coating process, sputtering plating, etc., which can solve the problems of limiting the development prospects of Invar alloy, poor opening precision, and rough hole walls. Achieve the effect of good opening quality, high opening precision and good coating surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

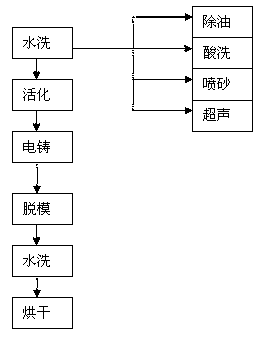

Image

Examples

Embodiment Construction

[0038] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0039] An embodiment of the present invention provides a metal mask for evaporation. The material of the metal mask for evaporation includes iron and nickel, wherein the iron content is 63% to 65%. The preferred metal mask for evaporation with an iron content of 63.8% is more similar to the composition percentage of Invar alloy, which can better meet the requirements of evaporation and improve the quality of evaporation products.

[0040] The surface brightness of the metal mask plate for evaporation is first-class brightness, and the uniformity of the plate surface is ≤5%. The metal mask plate for evaporation has the characteristics of high magnetic control performance, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com