Method for filling dam by combining sludge-filled bags and vacuum preloading

A technology of mud bags and dams, which is applied in dikes, dams, climate change adaptation, etc., can solve the problems of slow drainage and consolidation speed, and achieve the effect of saving engineering costs and significant reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

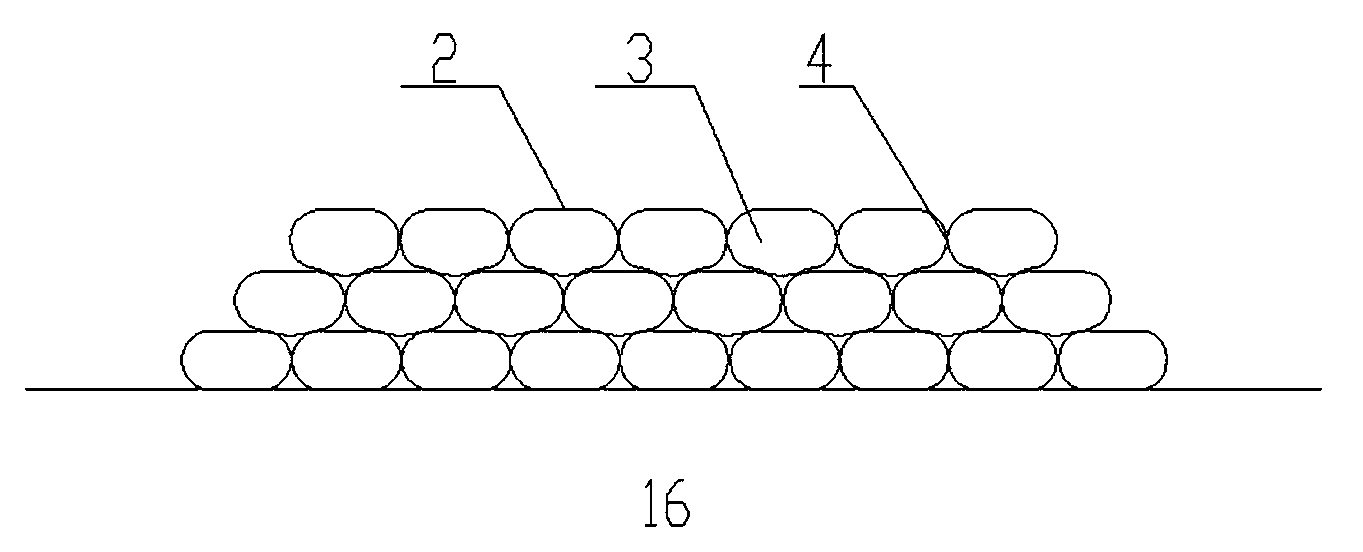

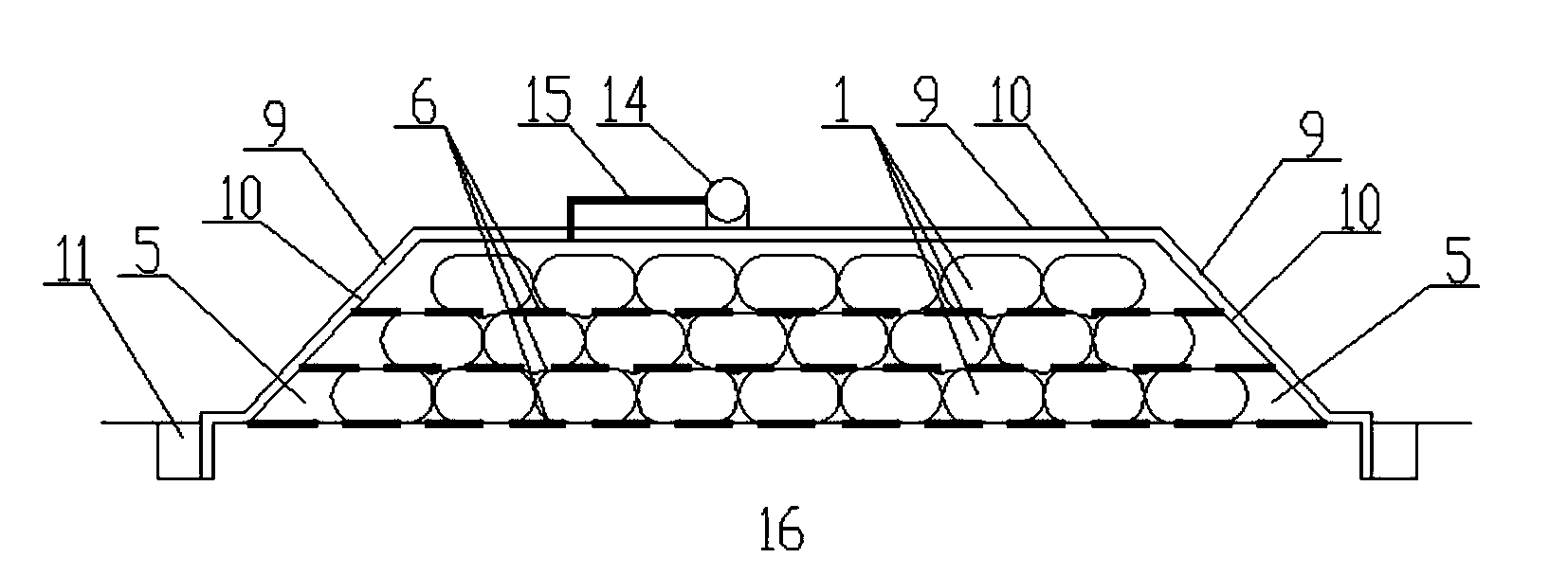

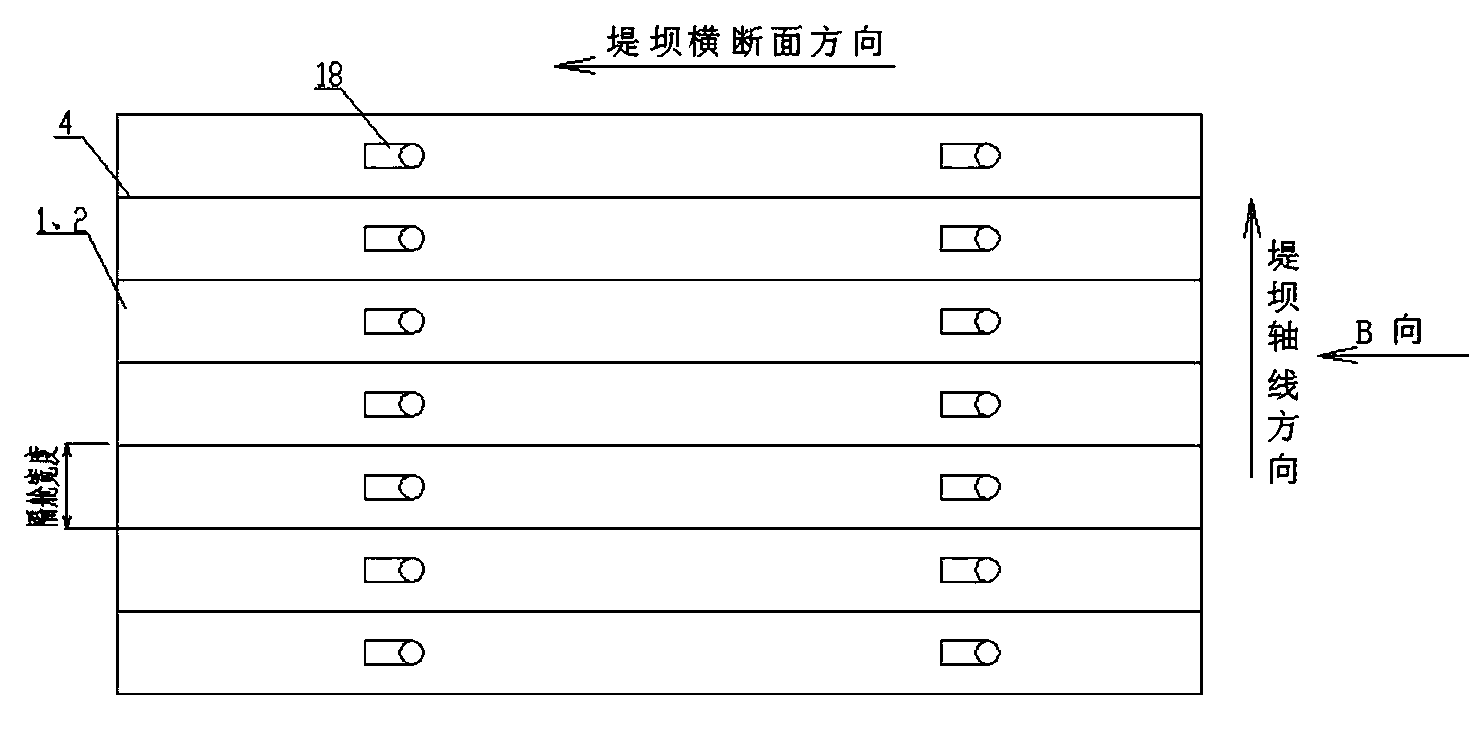

[0028] Embodiment one: see Figure 6 , on the beach or on the ground, all or part of the first structure of filling mud bags 1 is used (see image 3 , Figure 5 ), fill in layers to form the initial section of the embankment core structure; an interlayer drainage layer 6 (plastic drainage board, non-woven geotextile, drainage mat, permeable pipe) is set between the layers filled with mud bags 1, and the interlayer drainage Layer 6 is on both sides of the initial section of the embankment core structure and the surface drainage layer 5 (sand cushion, bagged sand cushion, bagged gravel cushion, bagged melon seed slice cushion, drainage sand quilt, non-woven geotextile , drainage mats, other non-adhesive material cushions) are connected. Lay the surface drainage layer 5 and the water filter pipe 10 on the surface of the initial section of the embankment core structure (including the top, side slopes, inner and outer platforms) and the beach surface or ground adjacent to the ini...

Embodiment 2

[0029] Embodiment two: see Figure 7 , the interlayer drainage layer 6 (plastic drainage board, non-woven geotextile, drainage mat, permeable pipe) and the second type interlayer drainage layer 7 (sand cushion, drainage sand quilt) are set in the interlayer combination of filling mud bag 1 , sand ribs, gravel cushions, bagged sand cushions, bagged gravel cushions, bagged melon seed slice cushions, and other non-adhesive material cushions), drain water on both sides of the initial section of the embankment core structure and on the surface Layer 5 (sand cushion, bagged sand cushion, bagged gravel cushion, bagged melon seed slice cushion, drainage sand quilt, non-woven geotextile, drainage mat, other non-adhesive material cushion) is connected. All the other are the same as embodiment one.

Embodiment 3

[0030] Embodiment three: see Figure 8 , on the beach or on the ground, the second structure of filling mud bags 1 is adopted in whole or in part (see Figure 4 , Figure 5 ), fill in layers to form the initial section of the embankment core structure. All the other are with embodiment two.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com