Method for constructing reinforced surrounding rock inside precast-segment tunnels

A construction method and technology in tunnels, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as the influence of segment integrity, difficulty in meeting first-level waterproofing, and danger of surrounding rock collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

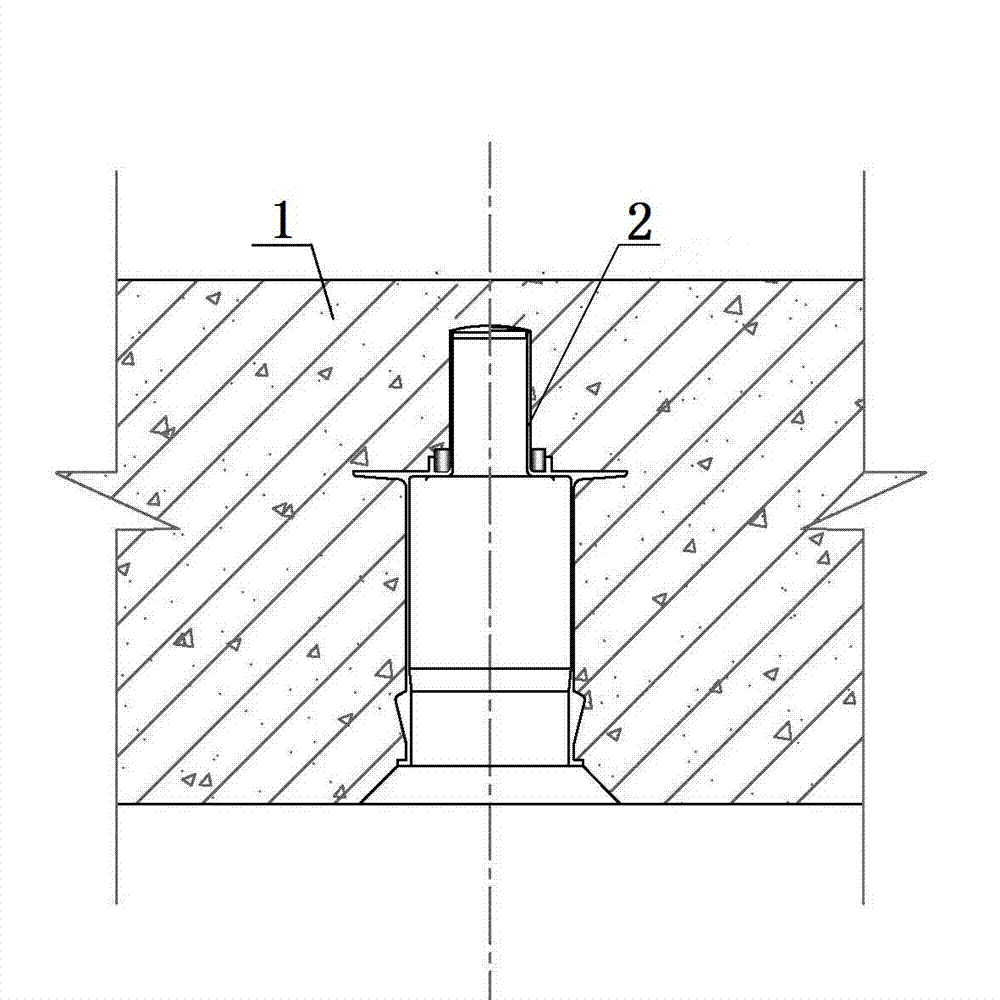

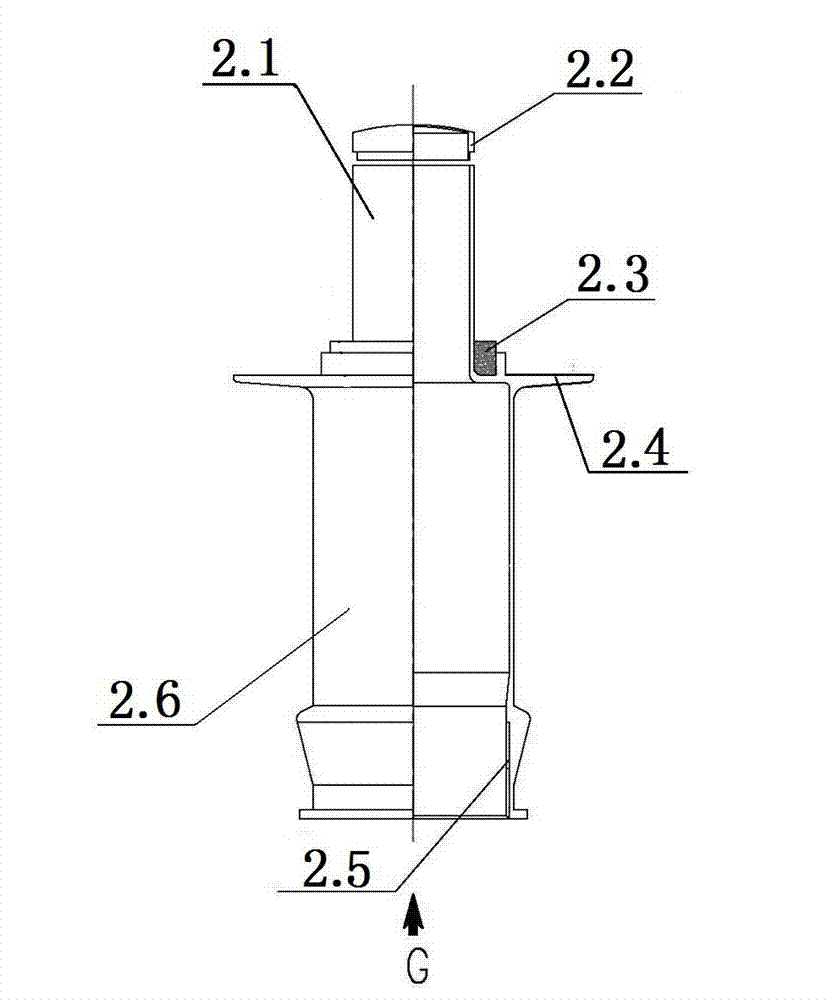

[0030] Example: such as Figure 1-16 As shown, this embodiment specifically relates to a construction method for reinforcing the surrounding rock in a prefabricated segment tunnel. This construction method is especially suitable for prefabricated segment tunnels with poor quality surrounding rock and large openings, and specifically includes the following construction steps :

[0031] ① if Figure 1-4 As shown, a prefabricated formwork 2 of appropriate size is selected according to the construction requirements, and it is pre-embedded in the formwork of the reinforced concrete prefabricated segment 1 and poured to form a prefabricated part. It is formed by axial connection with the large cylindrical shell 2.6, and a formwork end cap 2.2 is arranged at the port of the small cylindrical shell 2.1 to seal the nozzle to prevent the inflow of concrete slurry during prefabrication; on the inner wall of the port of the large cylindrical shell 2.6 There is an internal thread 2.5, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com