Achieving method for low-power high-frequency ultrasonic power source

A technology of high-frequency ultrasonic wave and realization method, which is applied in the direction of instruments, computer control, simulators, etc., can solve the problems of inflexible use, inconvenient experiment, high power consumption, etc., and achieve simple body and circuit structure, easy mass production, and low power consumption. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

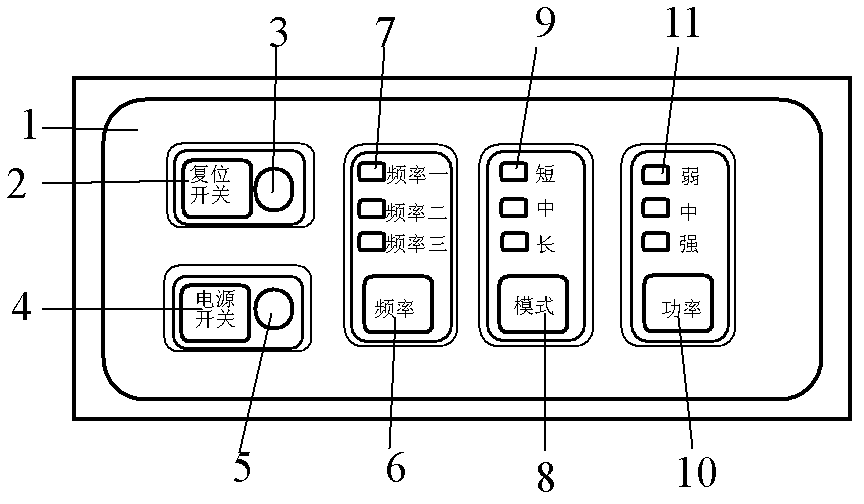

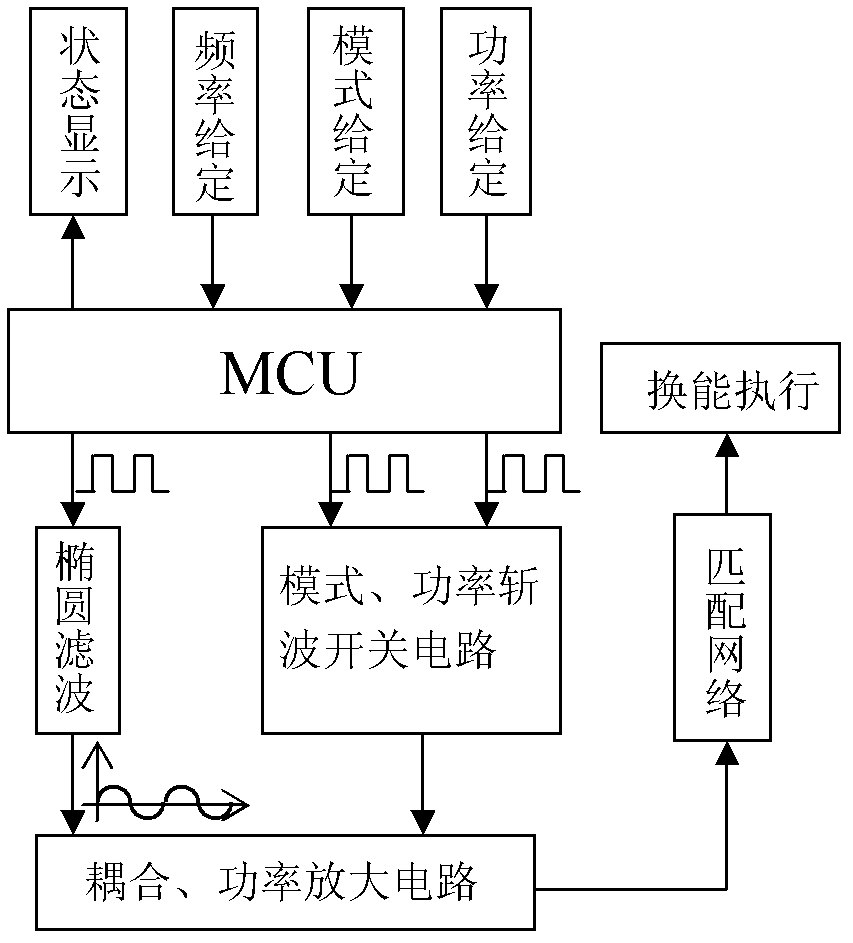

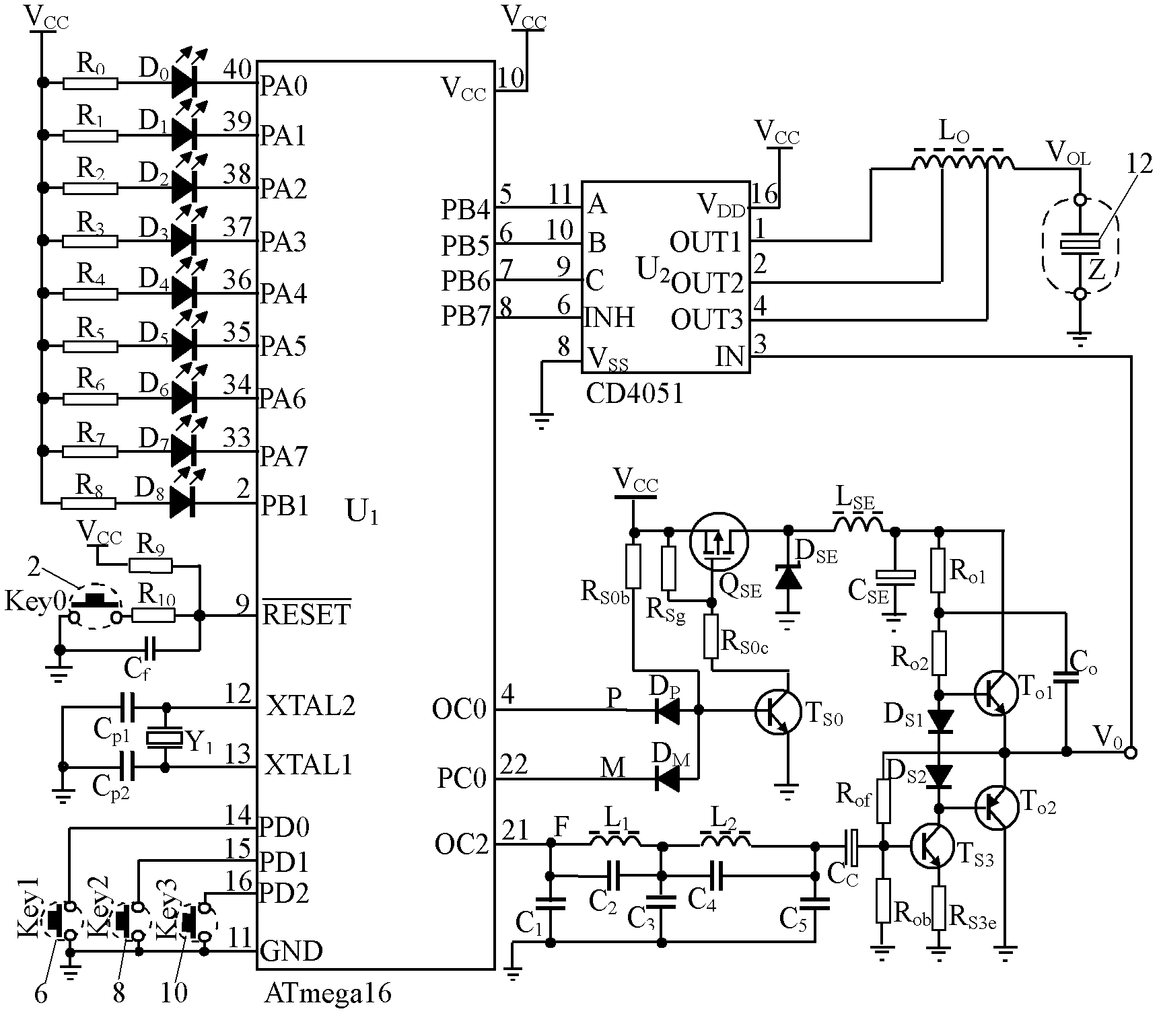

[0019] The power supply device adopts the design method of combining software and hardware. Through programming the ATmega16 single-chip microcomputer, three single buttons are used to control frequency setting, mode setting and power setting, corresponding matching inductance access and corresponding indicator light on and off. The specific implementation process of the frequency setting is to output the square wave signal with the required frequency by programming the single-chip microcomputer. At the same time, according to the different access frequencies, use the single-chip microcomputer programming to control the single 8-channel digital control analog electronic switch, so that the channel corresponding to the switch conducts the matching inductance. Connect the matching inductance corresponding to the frequency, and at the same time the working status indicator light corresponding to the frequency is on; the specific realization process of the given mode is to use the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com