Chemical feeding reflux stirrer

A technology of reflux stirring and dosing device, which is applied in the direction of chemical instruments and methods, dissolving, mixing machines, etc. It can solve the problems of inability to achieve fast dissolution of medicines, cannot meet the requirements of rapid dissolution of medicines, and large doses of medicines, and achieve the dissolution rate of medicines Efficient, improve the dissolution rate of dosing, and the effect of reasonable dosing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

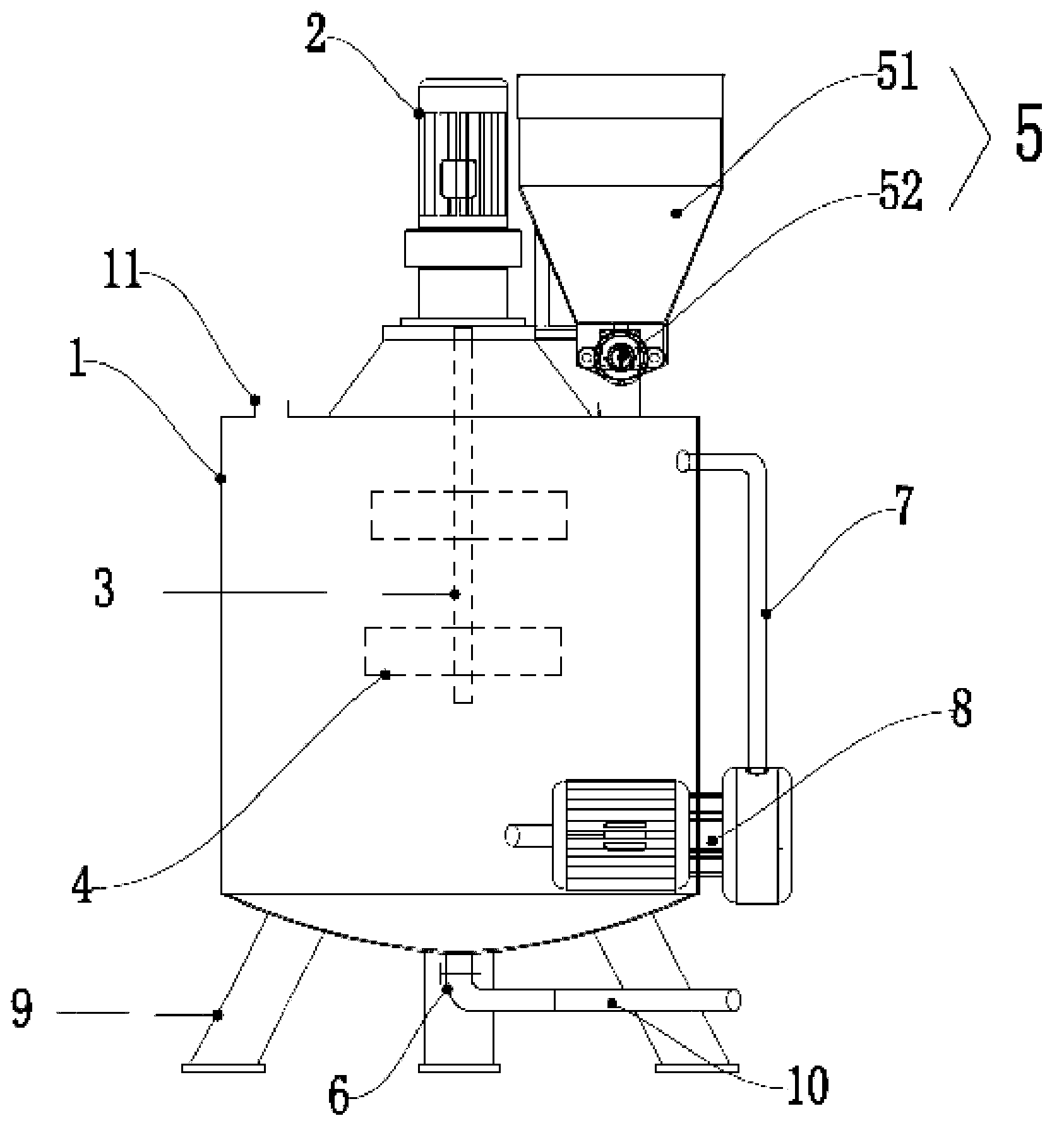

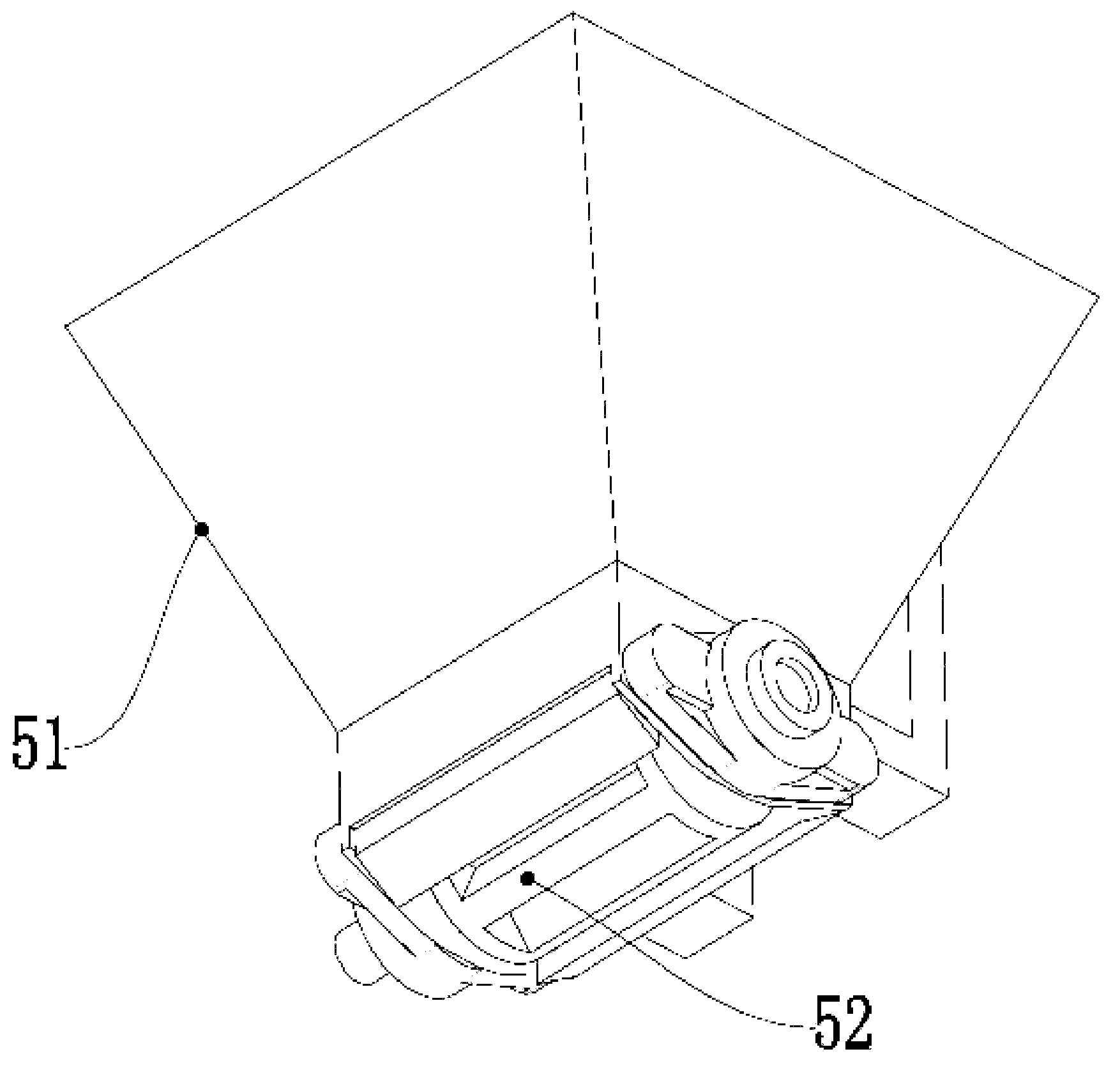

[0021] The dosing reflux mixer of the present embodiment is as figure 1 As shown, it includes a mixing tank 1 , a stirring motor 2 , a stirring shaft 3 , a stirring blade 4 , a drug feeder 5 , a liquid outlet 6 , a return pipeline 7 and a return drug pump 8 . The mixing tank 1 is made of circular stainless steel, because the chemical stability of stainless steel is high, it can resist chemical corrosion for a long time and prolong the service life, and the circular structure can place more solutions and improve work efficiency; The stirring shaft 3 adopts a steel support to be installed in the center of the mixing tank 1, and the steel support can make the stirring shaft 3 have stronger mechanical strength and is not easily damaged; one end of the stirring shaft 3 is installed on the stirring motor 2, and the stirring The other end of the shaft 3 extends vertically to the inside of the mixing bucket 1, one end of the stirring blade 4 is installed on the stirring shaft 3, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com