System and method for deep arsenic removal through coagulation

A technology of coagulation and depth, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water pollutants, etc., can solve the problems of cost increase, not widely used, unsatisfactory effect, etc., to achieve volume reduction, The effect of ensuring safety during the flood season and reducing the amount of sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

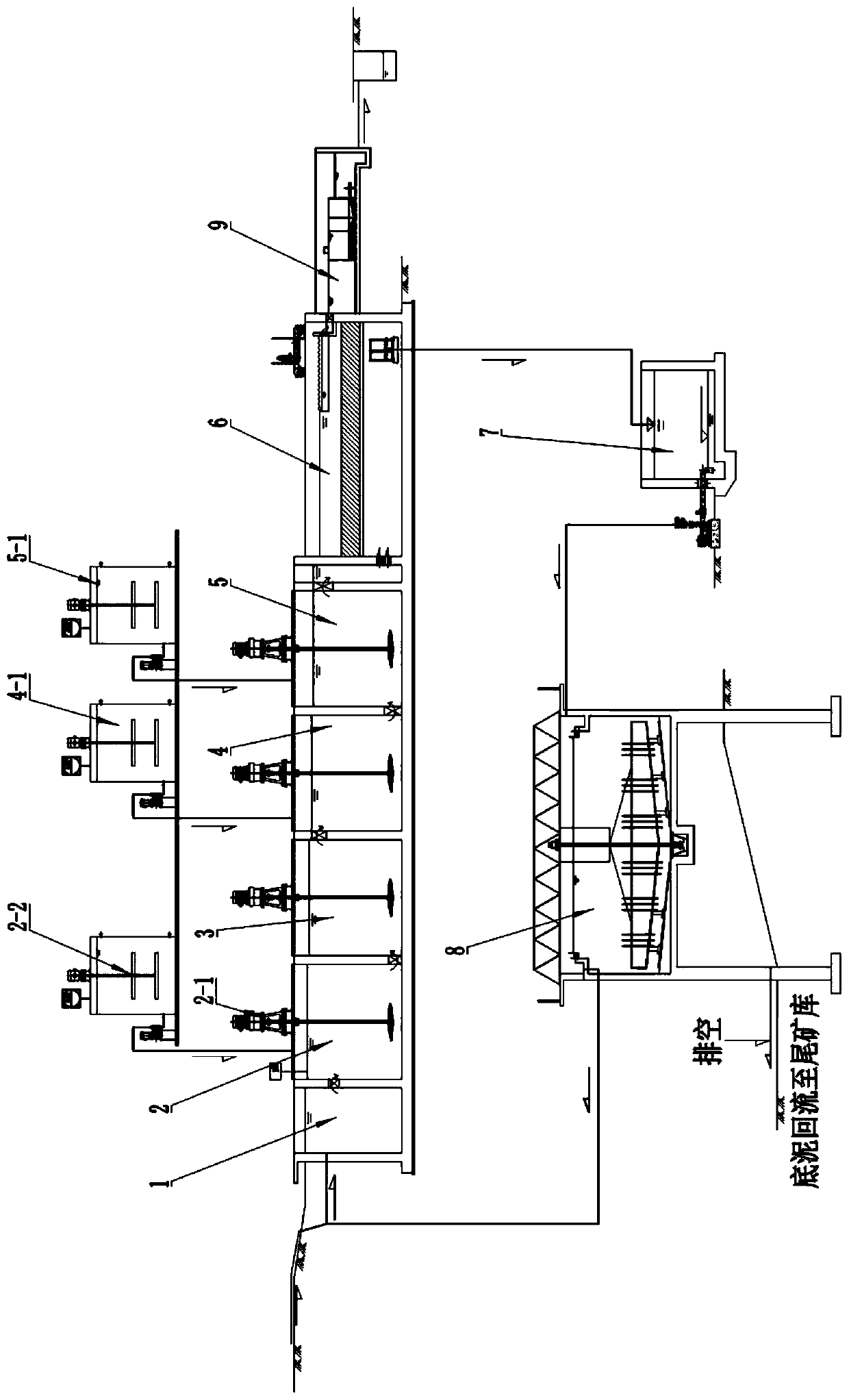

[0024] A coagulation deep arsenic removal system, comprising: distribution tank 1, primary reaction tank 2, secondary reaction tank 3, third-level reaction tank 4, fourth-level reaction tank 5, inclined tube sedimentation tank 6, mud storage tank 7 and Sludge thickening tank 8, and connected in sequence;

[0025] The distribution pool 1 is connected to the wastewater in the underwater well warehouse through a water pump; the primary reaction pool 2, the secondary reaction pool 3, the tertiary reaction pool 4, and the fourth-stage reaction pool 5 are all equipped with agitator 2-1; the primary reaction pool 2 is connected to PFS dosing system 2-2, the third-stage reaction tank 4 is connected to the alkali dosing system 4-1, the fourth-stage reaction tank 5 is connected to the PAM dosing system 5-1; the upper side of the sedimentation tank 6 is provided with a drain port and connected to Bache The tank 9 has a sludge outlet at the bottom and is connected to the sludge storage ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com