Multi-parameter field automatic measuring and sorting system

An automatic measurement and sorting system technology, applied to measuring devices, sorting, instruments, etc., to achieve high measurement efficiency, reduce labor costs, and improve detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

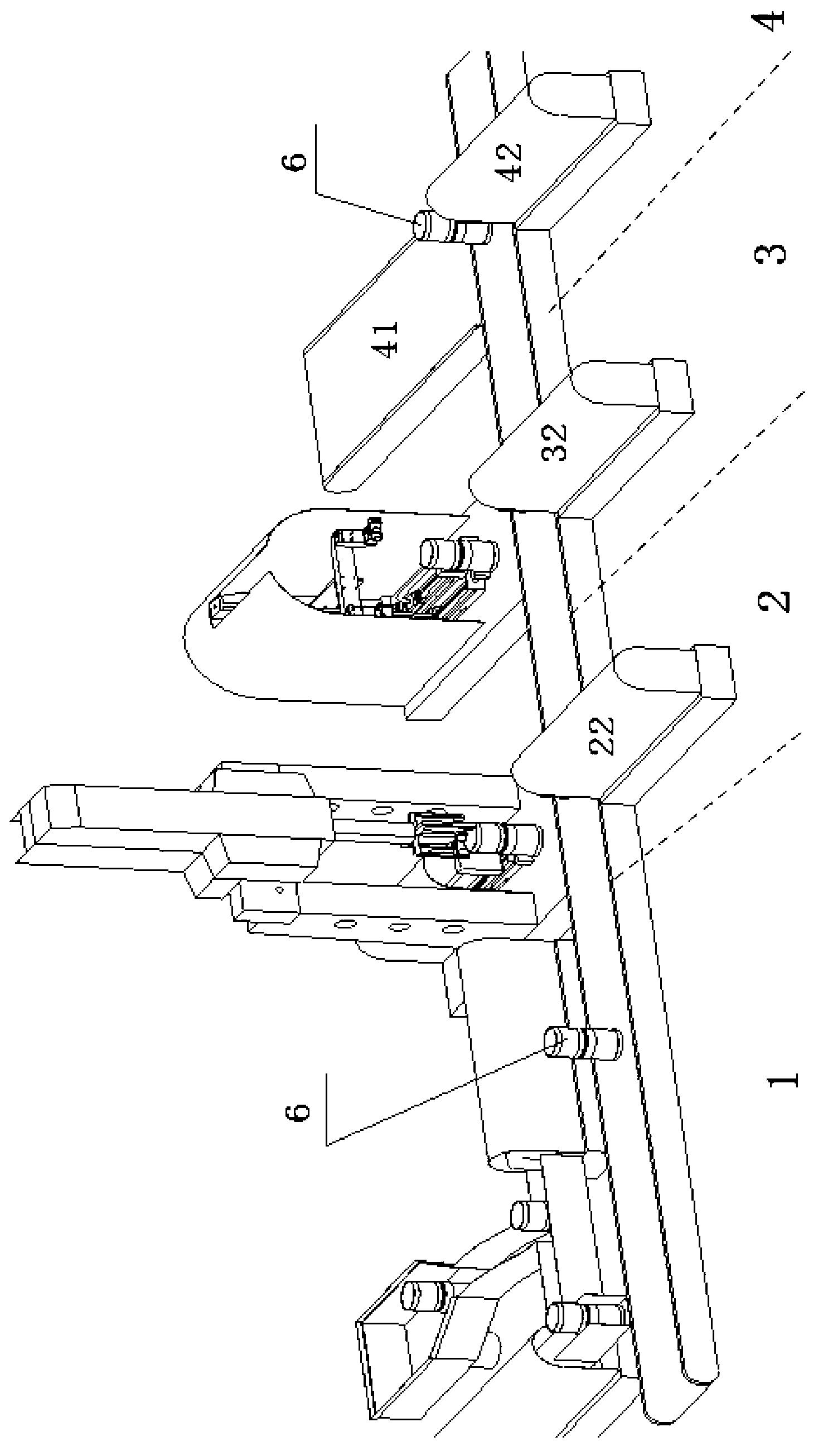

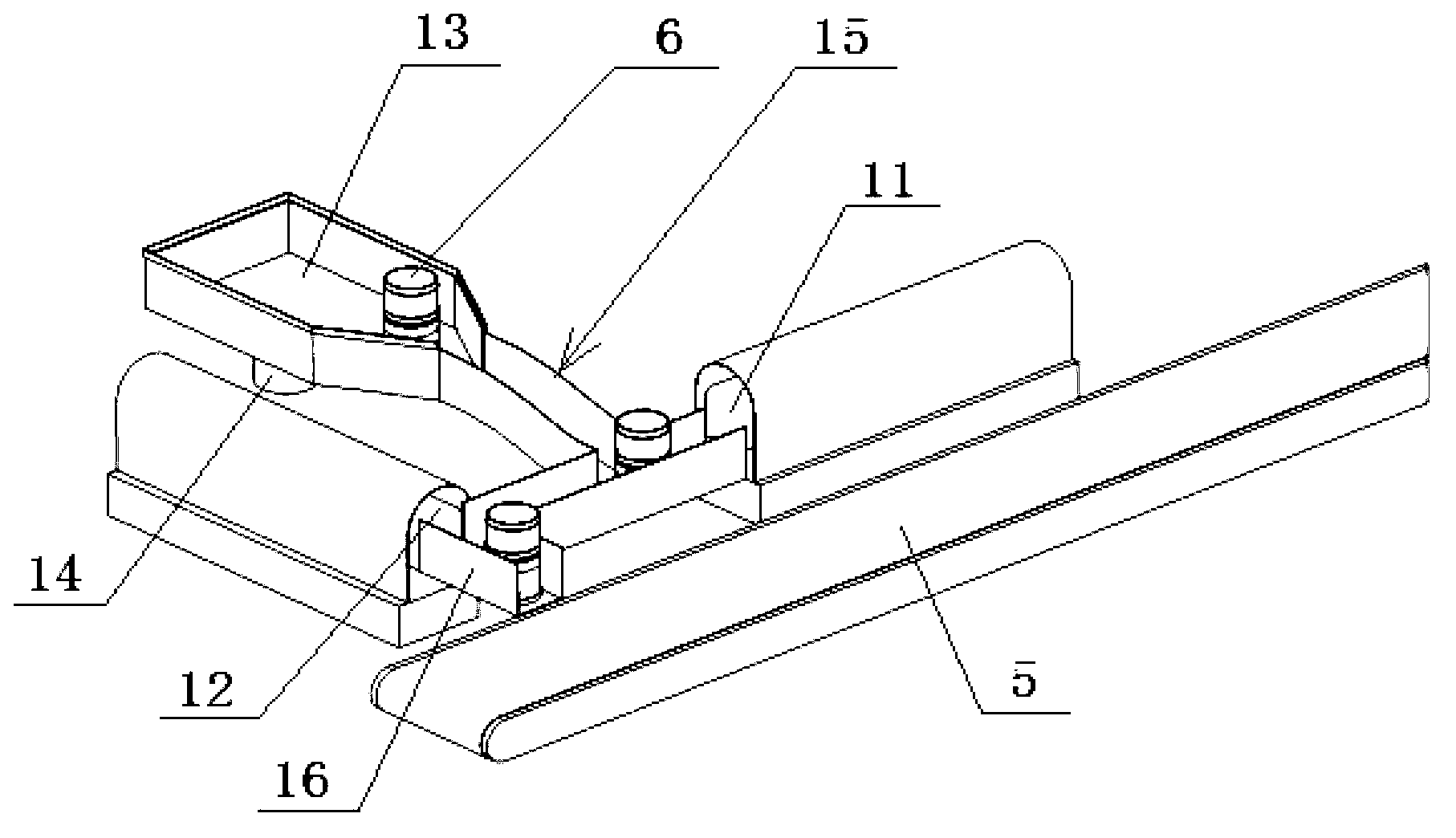

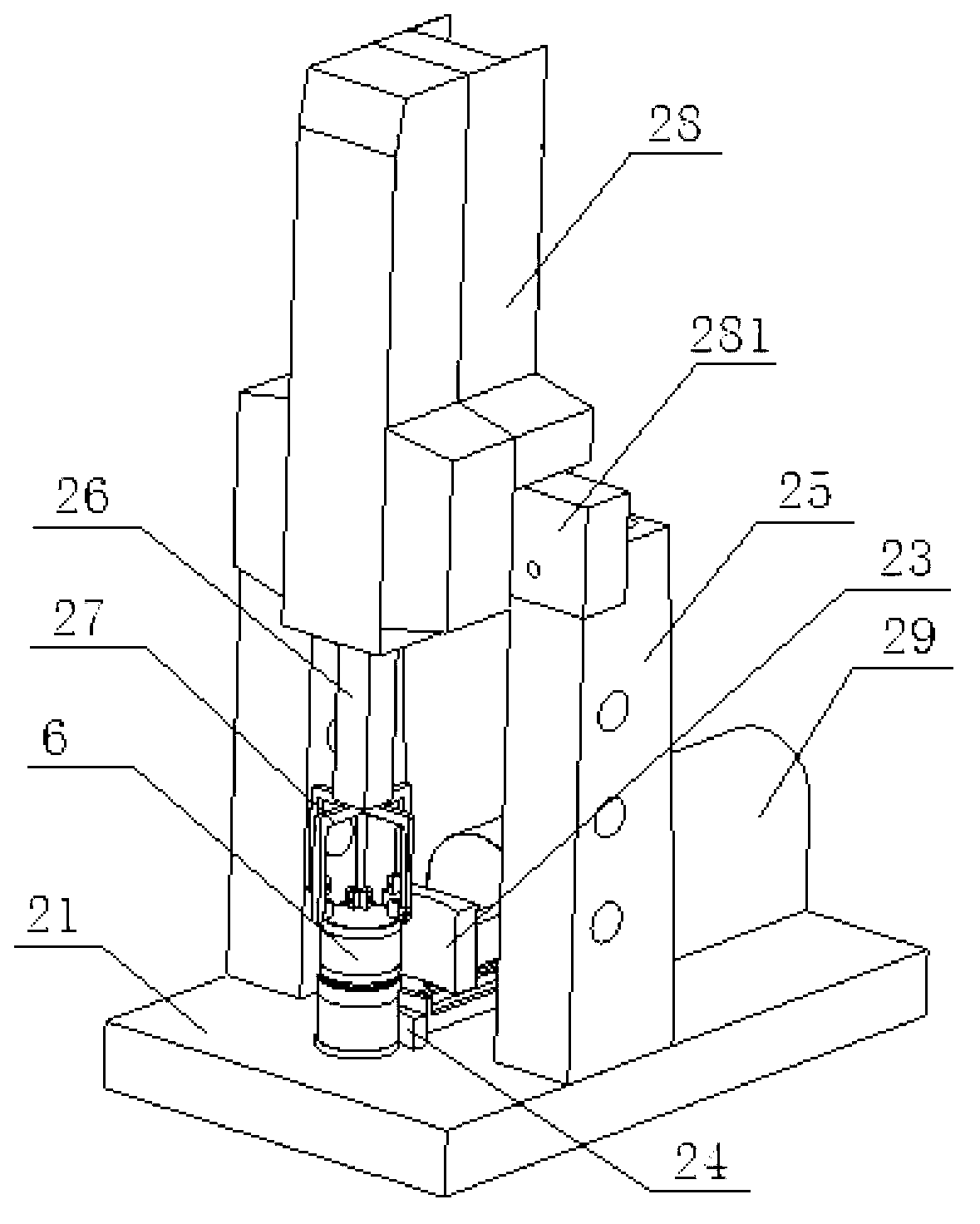

[0062] The multi-parameter on-site automatic measurement and sorting system of the present invention will be described in detail below in conjunction with the embodiments and drawings.

[0063] The multi-parameter on-site automatic measurement and sorting system of the present invention provides a real-time detection method for industrial on-site measurement of cylinder liner parts of internal combustion engines. The densely packed parts are separated by the automatic feeding system, and the distance between every two adjacent parts is the interval between two measuring stations. Then the parts are inspected by two measuring stations. During the operation of the system, the two stations are always in measurement at the same time, and the first measuring station completes the cylinder with a non-contact measuring head based on laser self-mixing technology. The geometric size and shape error detection of the sleeve parts, the second measuring station obtains the contour informat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com