Hydraulic type external thread cold rolling device

A technology of external thread and cold rolling, which is applied in the field of mechanical processing appliances, can solve problems such as drilling tool breakage, and achieve the effects of easy production, quality assurance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

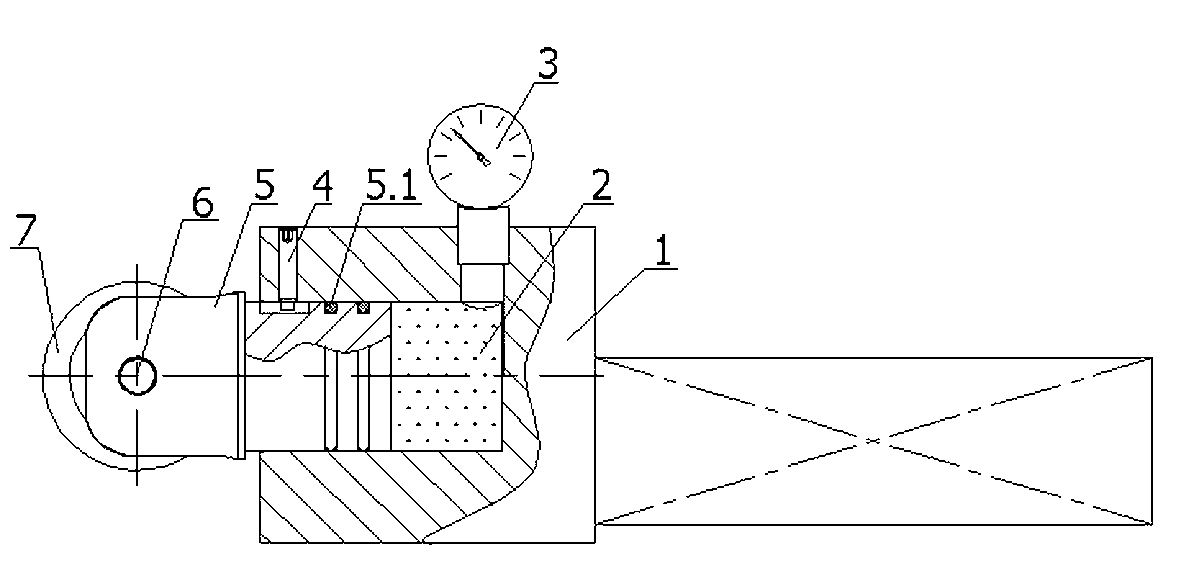

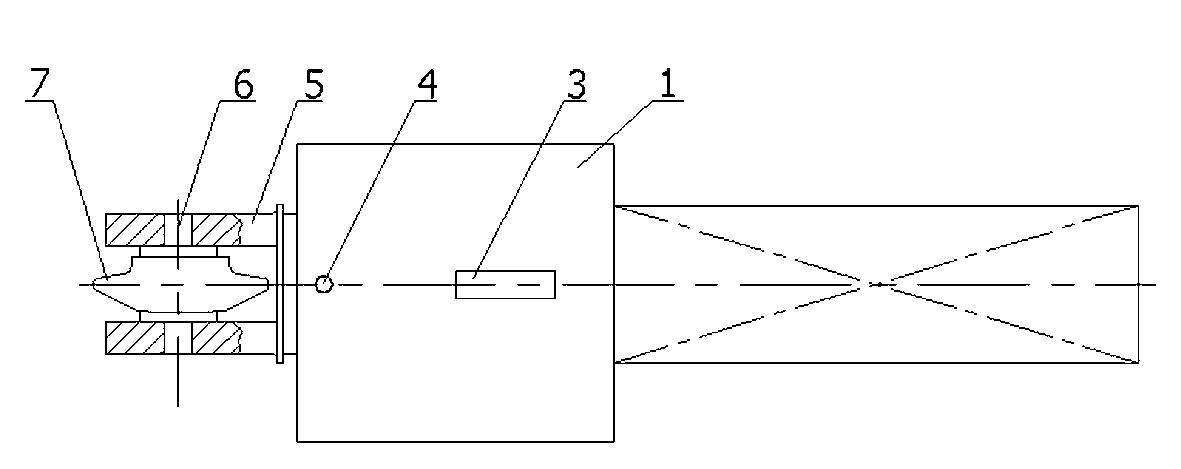

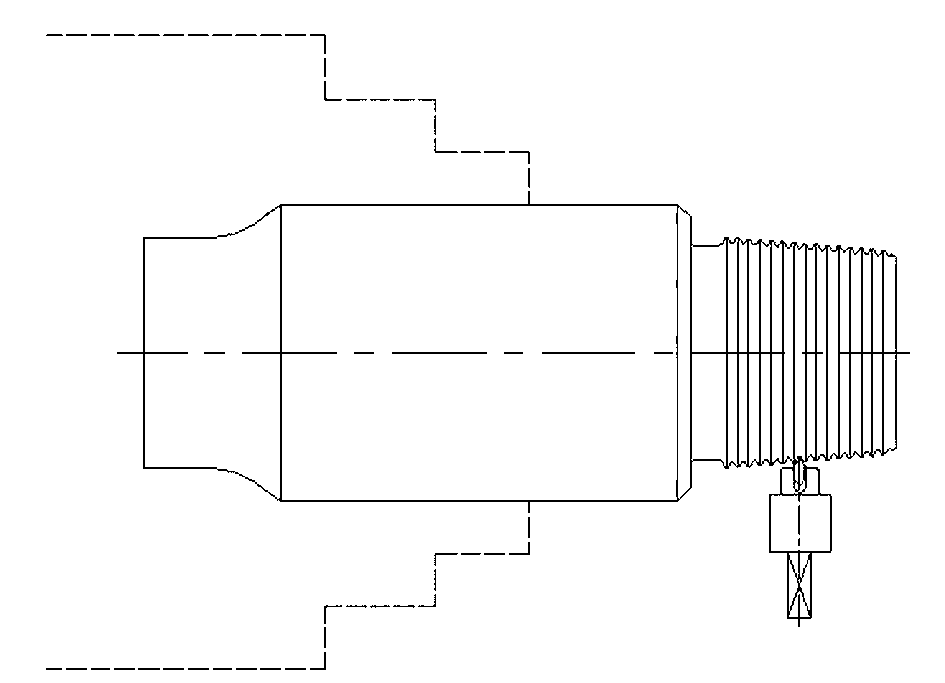

[0015] figure 1 The hydraulic external thread cold rolling device shown includes a cantilever 1, hydraulic oil 2, a pressure gauge 3, a pin 4, a fork shaft 5, a mandrel 6 and a roller 7. The fork shaft 5 is a straight rod member, and the outward shaft end is provided with an open groove, and the roller 7 is installed in the open groove through the mandrel 6 , and the roller 7 rotates freely around the mandrel 6 . In this embodiment, the external thread of the oil drilling tool joint is rolled, and the thread is triangular, so the outer rim transverse section of the roller 7 is angular, and its angle is equal to the angle of the external thread of the oil drilling tool joint being rolled. In order to improve the quality of cold rolling, the roller 7 is hardened as a whole to HRC50-55. The top of the outer wall of the middle part of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com