Cyclone-type waste plastic crushing, sorting, and washing method and system

A cleaning system and technology of waste plastics, applied in the field of waste plastics recycling, can solve the problems of difficult handling of flotation media, high cost, environmental pollution, etc., to improve sorting and cleaning effects, improve processing efficiency, and realize continuity and automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

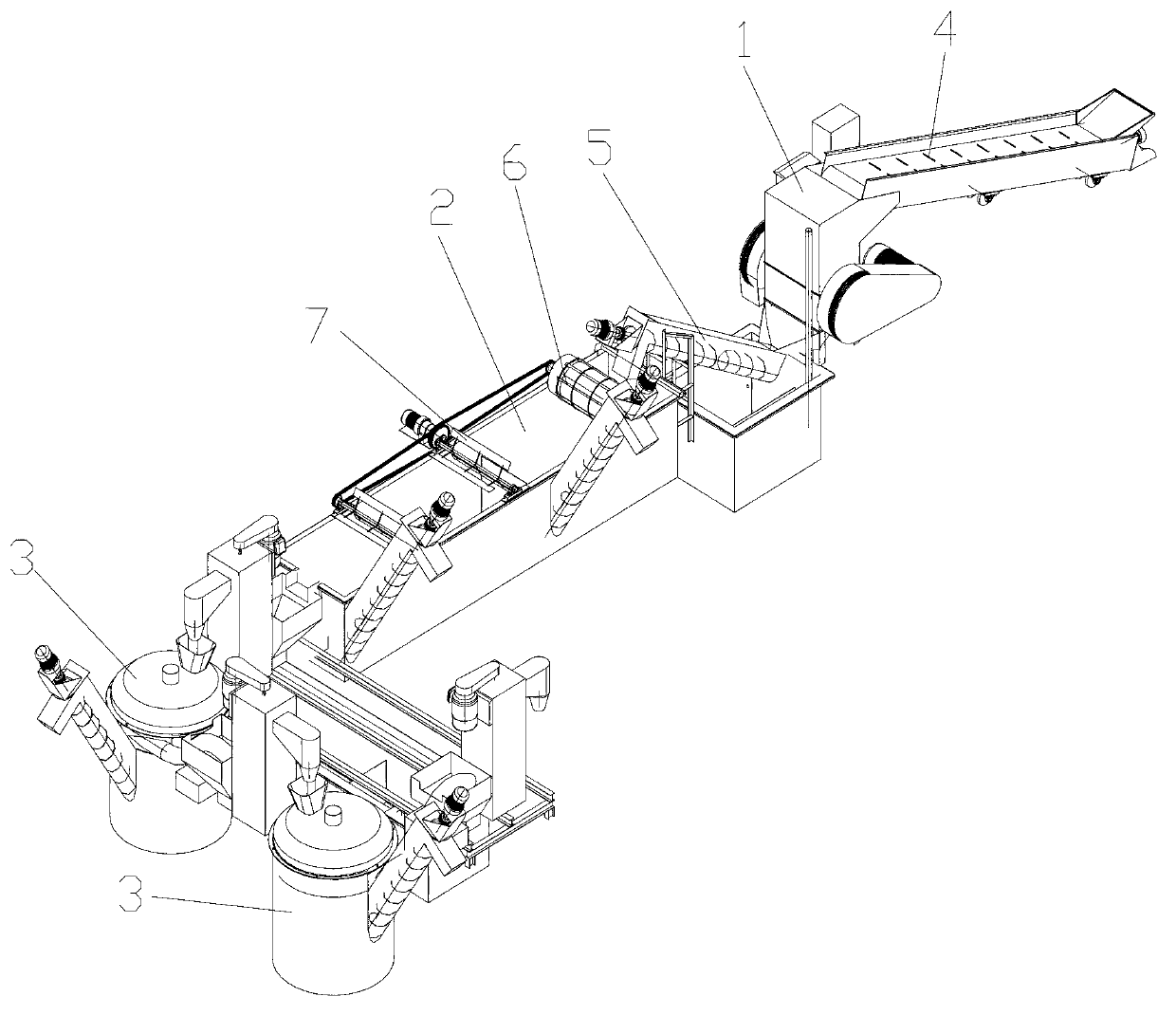

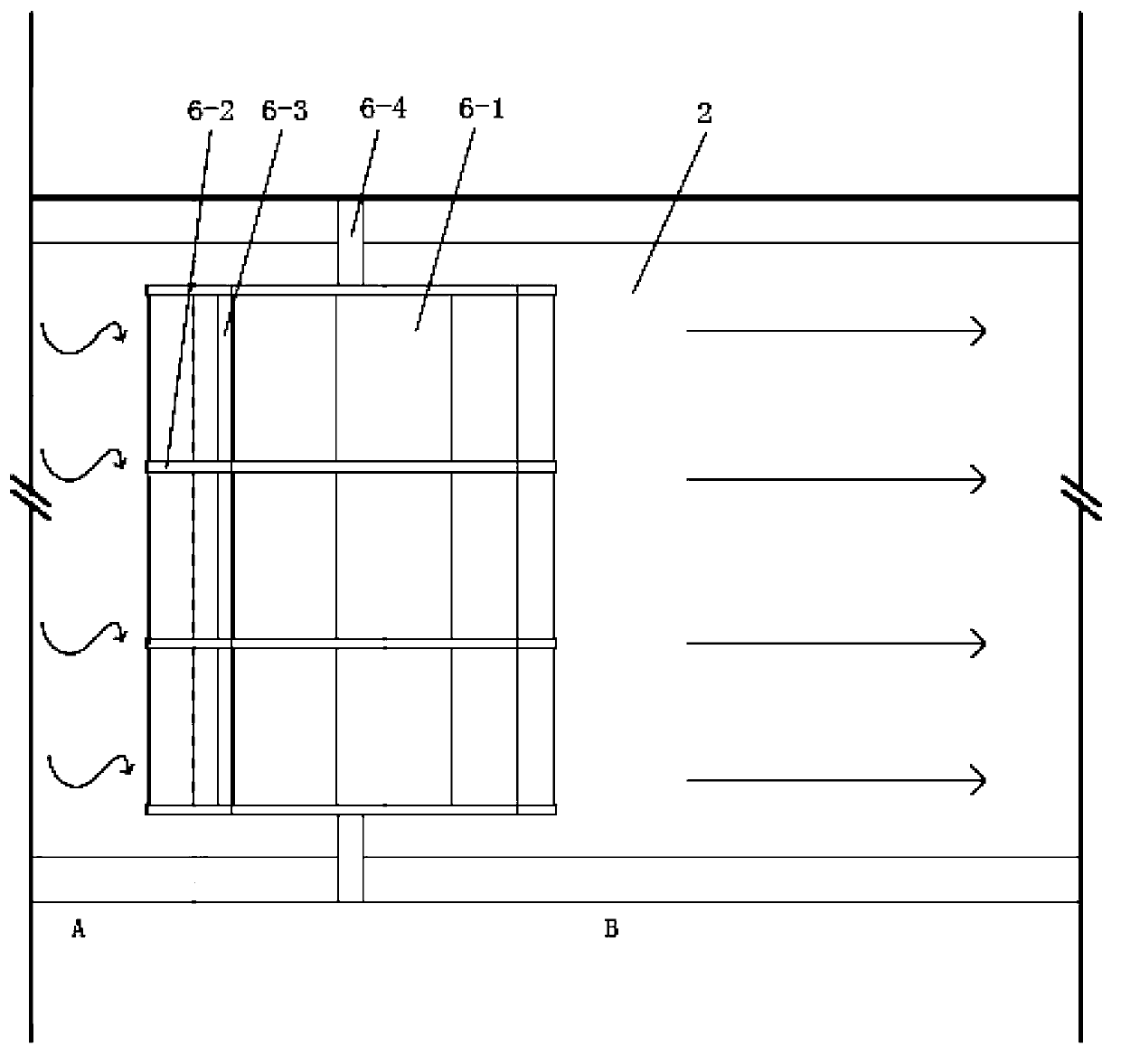

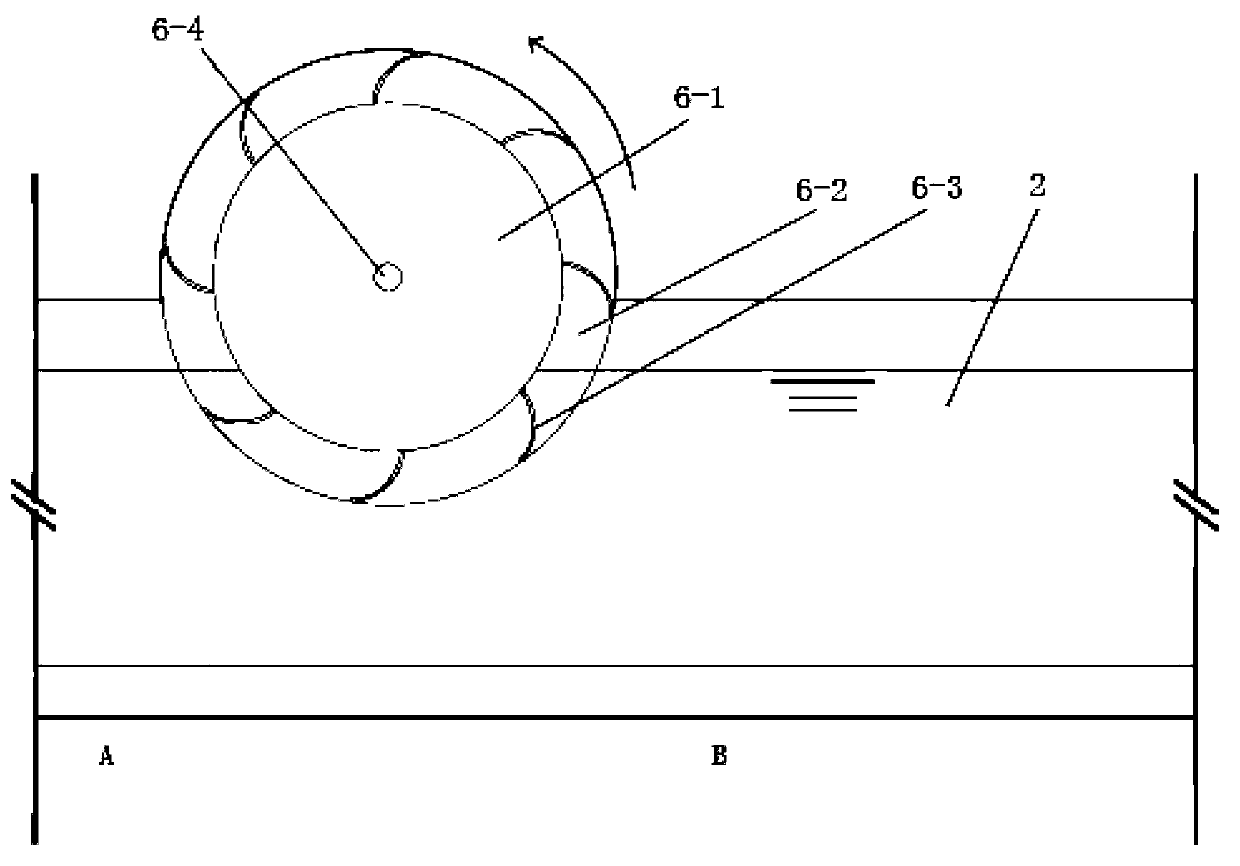

[0042] figure 1 The swirl-type waste plastic crushing, sorting and cleaning system shown includes: a feeding mechanism, a crusher, a screw elevator, a flotation tank, and multiple (two in this example) ) A cyclone sorting and cleaning device connected in series.

[0043] The feeding mechanism is a belt conveying feeding mechanism.

[0044] The shredder is an existing plastic shredder, which cuts waste plastics into waste plastic fragments.

[0045] The screw elevator is located between the crusher and the flotation tank. Or place the crusher high on the flotation tank, and use gravity to drop the broken pieces into the flotation tank.

[0046] The flotation cell is a linear launder, the outlet of the flotation cell is located at one end of the flotation cell, and the feed port of the flotation cell is located at the other end of the flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com