Separating and purifying system for sulfur hexafluoride and carbon tetrafluoride

A technology of sulfur hexafluoride and carbon tetrafluoride, which is applied in the field of separation and purification, and gas recovery, can solve the problems that do not involve CF4 separation and purification, and achieve the effect of complete functions and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

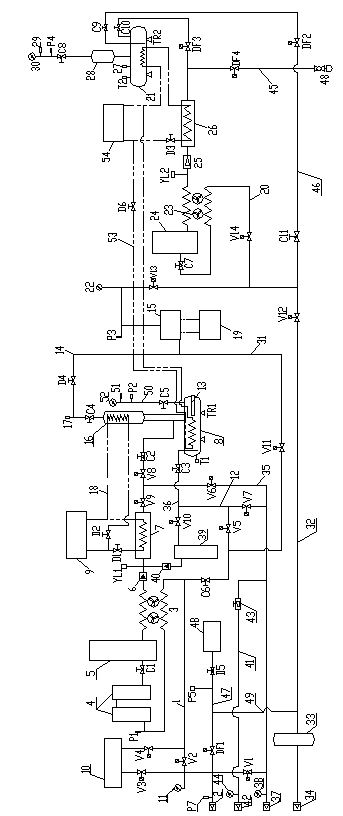

[0020] like figure 1 As shown, the separation and purification system of sulfur hexafluoride and carbon tetrafluoride of the present invention includes a mixed gas recovery pipeline, and the mixed gas recovery pipeline is respectively connected with a circulation purification pipeline, a sulfur hexafluoride purification pipeline and tetrafluoride Carbon purification lines.

[0021] The mixed gas recovery pipeline includes a recovery port self-sealing joint 2, a first solenoid valve V2, an air cooler 3, a molecular sieve 4, a first manual normally open valve C1, and a first compressor 5, which are connected in sequence through the first high-pressure pipe 1 , air cooler 3 bypass, first one-way valve 6, first cold heat exchanger 7, second solenoid valve V9, third solenoid valve V8, second manual normally open valve C2 and sulfur hexafluoride purification tank 8. The first cold and heat exchanger 7 is connected to the first refrigerator 9 through the fourth solenoid valve D1; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com