Method for preparing phosphorus iron alloy by utilizing high-phosphorus iron ore and medium and low-grade phosphorus ore

A technology of high-phosphorus iron ore and phosphorus-iron alloy, which is applied in the field of preparation of phosphorus-iron alloy, can solve the problems of high processing cost, difficulty in mineral processing, waste of resources, etc., and achieve broad application prospects, high added value of products, and low environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

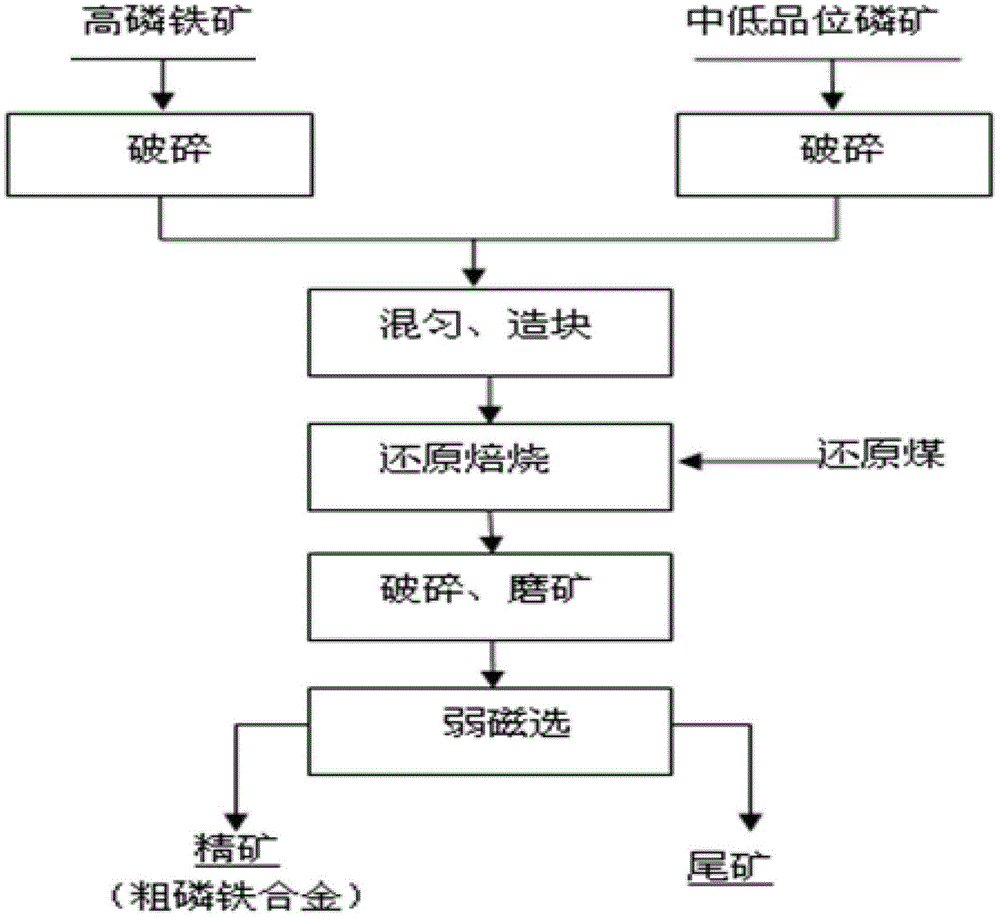

[0052] see figure 1 , mix the pre-broken high-phosphorus oolitic hematite to -3mm and medium and low-grade phosphate rock at a mass ratio of 4:6, and then make agglomerates. The medium and low-grade phosphate rock is P 2 o 5 Phosphate ore resources with a content of less than 26%; the dried agglomerates are reduced and roasted with coal as a reducing agent, the roasting temperature is 1180°C, and the roasting time is 100 minutes; the cooled reduced agglomerates are crushed and ground to less than 0.074mm The particle size accounts for 92.3% of the mass percentage, and the final product crude phosphorus ferroalloy is obtained by weak magnetic separation with a magnetic field strength of 1100Oe. The iron grade is 79.2% and the phosphorus content is 14.8%.

Embodiment 2

[0054] see figure 1 , mix the pre-broken high-phosphorus oolitic hematite to -3mm and medium-low-grade phosphate rock at a mass ratio of 7:3 and then make agglomerates. The medium-low-grade phosphate rock is P 2 o 5 Phosphate ore resources with a content of less than 26%; the dried agglomerates are reduced and roasted with coal as a reducing agent, the roasting temperature is 1150°C, and the roasting time is 120 minutes; the cooled reduced agglomerates are crushed and ground to less than 0.074mm The particle size accounts for 90% of the mass percentage, and the final product crude phosphorus ferroalloy is obtained by weak magnetic separation with a magnetic field strength of 900Oe. The iron grade is 88.3% and the phosphorus content is 5.0%.

Embodiment 3

[0056] see figure 1 , mix the pre-broken high-phosphorus oolitic hematite to -3mm and medium and low-grade phosphate rock at a mass ratio of 3:7, and then make agglomerates. The medium and low-grade phosphate rock is P 2 o 5 Phosphate ore resources with a content of less than 26%; the dried agglomerates are reduced and roasted with coal as a reducing agent, the roasting temperature is 1200°C, and the roasting time is 90 minutes; the cooled reduced agglomerates are crushed and ground to less than 0.074mm The particle size accounts for 94.8% of the mass percentage, and the final product crude phosphorus ferroalloy is obtained by weak magnetic separation with a magnetic field strength of 1300Oe. The iron grade is 74.4% and the phosphorus content is 20.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com