Heat treatment method for improving titanium-nickel-chromium shape memory alloy superelasticity

A heat treatment method and memory alloy technology, which is applied in the field of alloy processing, can solve the problems of not specifically improving the superelasticity of titanium-nickel-chromium memory alloys, and achieve good plasticity, high driving force, and non-deformable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

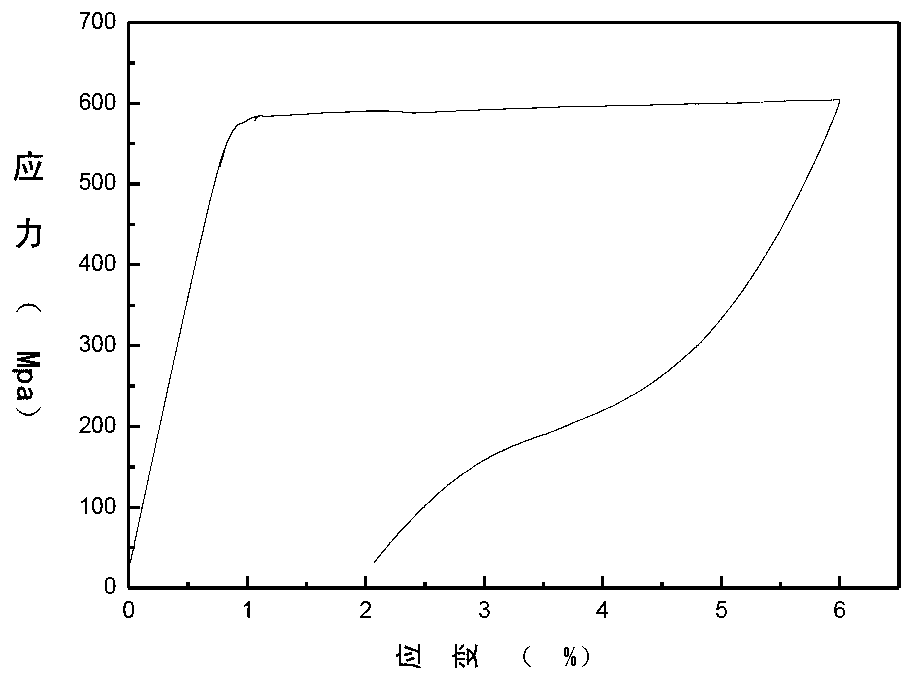

Embodiment 1

[0023] The titanium-nickel-chromium shape memory alloy was heated at 750° C. for 30 minutes, then heated at 400° C. for 5 minutes, and finally cooled with water.

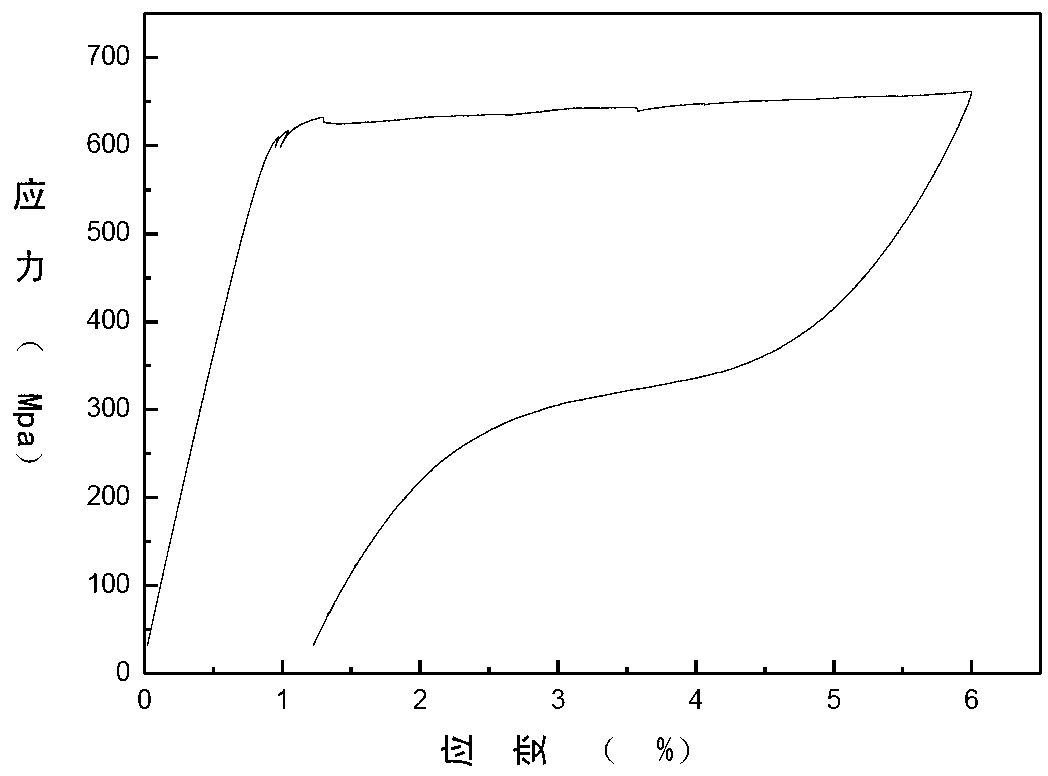

Embodiment 2

[0025] The titanium-nickel-chromium shape memory alloy was heated at 750° C. for 30 minutes, then heated at 400° C. for 8 minutes, and finally cooled with water.

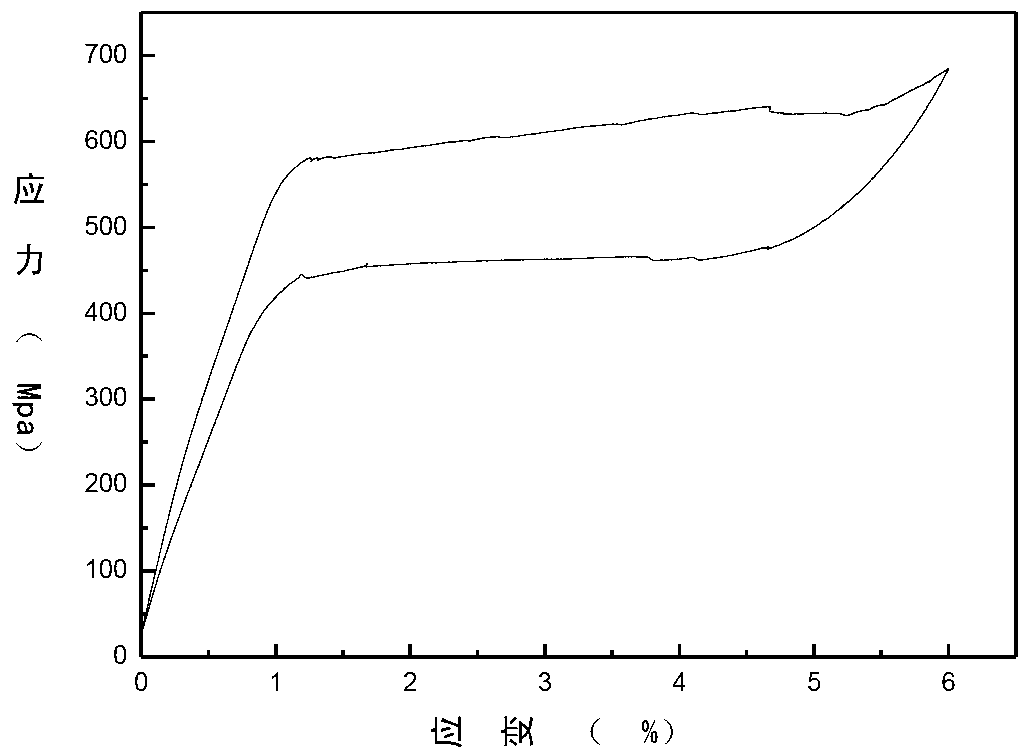

Embodiment 3

[0027] The titanium-nickel-chromium shape memory alloy was heated at 750° C. for 30 minutes, then heated at 400° C. for 12 minutes, and finally cooled with water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com