Method for underwater processing bridge deformed steel retaining cylinder

A processing method and technology for steel casing, which are applied in construction, sheet pile wall, infrastructure engineering, etc., can solve the problems of difficult construction and high processing cost of deformed steel casing, achieve easy quality control, reduce construction cost, and speed up construction. effect of progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

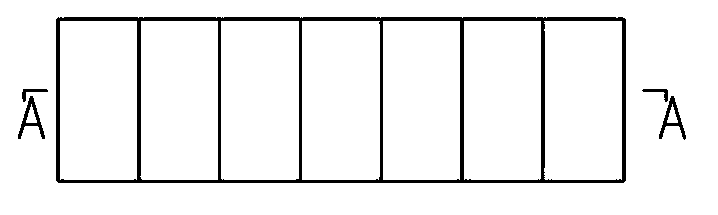

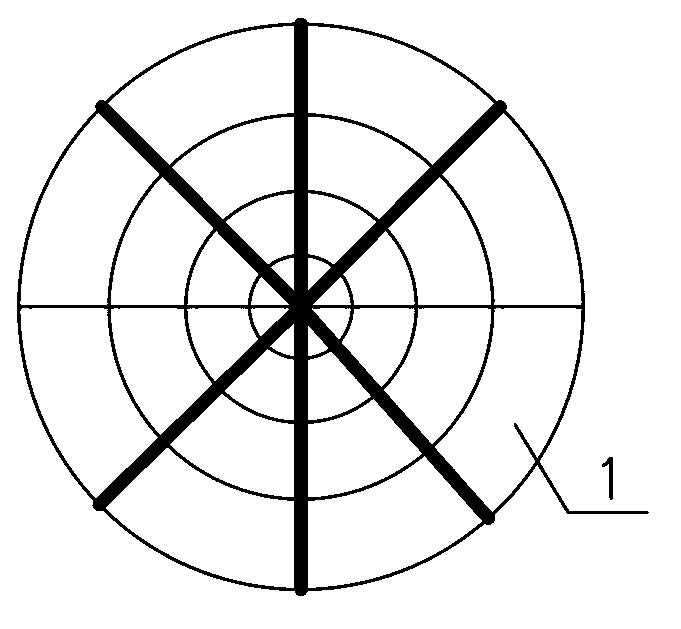

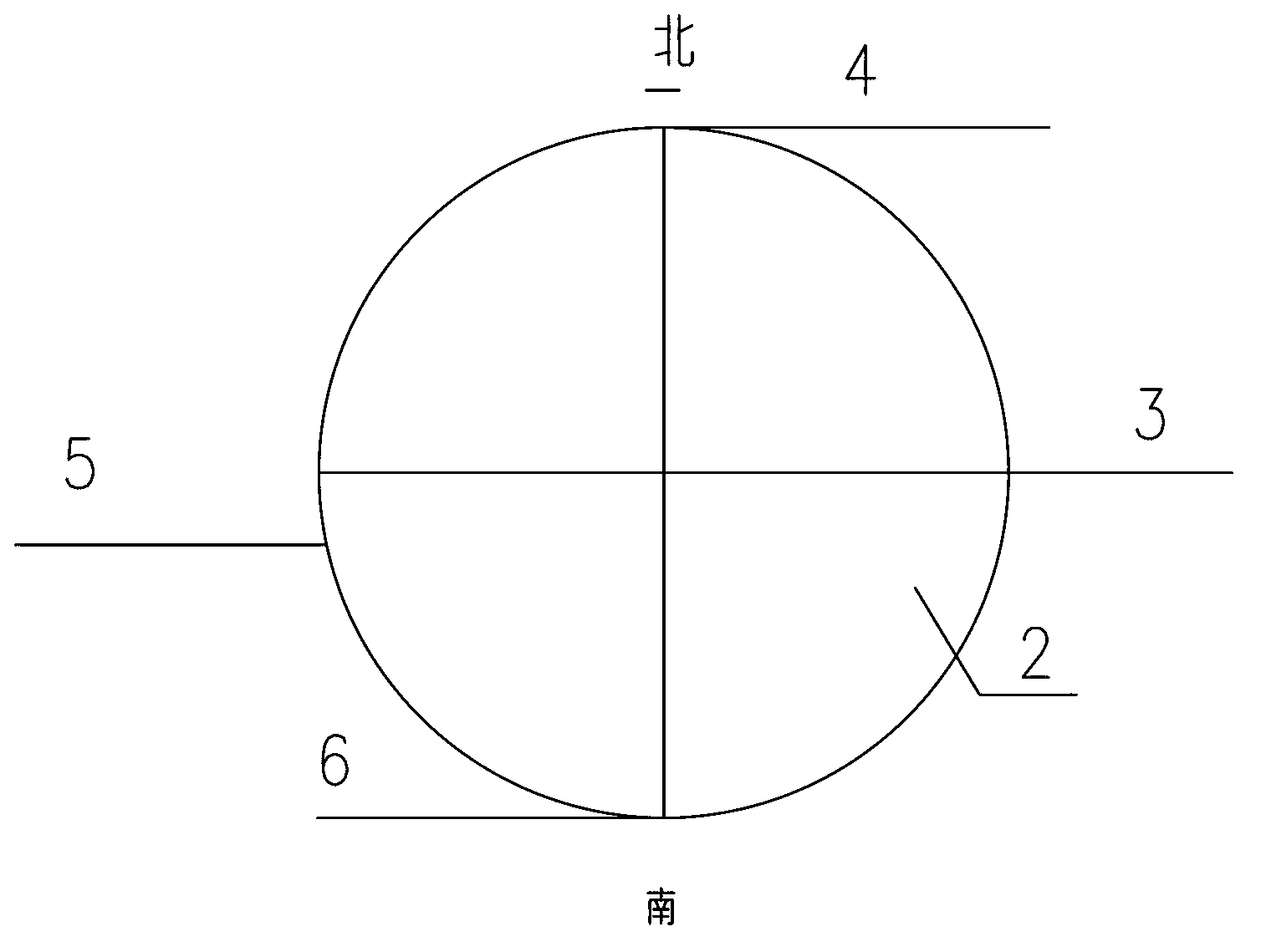

[0027] 1. Underwater cutting of deformed steel casing

[0028] 1. Sweeping holes and changing pulp of steel casing

[0029] Before the underwater cutting of the deformed steel casing, it is necessary to sweep the hole and change the slurry. Usually, a drilling rig is used to sweep the deformed steel casing, and 12 wire ropes are added on the belt of the sweeping drill bit to clean up the mud on the inner wall of the steel casing. When sweeping the hole, the belt under the drill bit is required to pass through the bottom of the steel casing for 2.0-2.5m, so as to ensure the smooth progress of the underwater cutting construction.

[0030] In order to reduce sedimentation in the hole and reduce the pressure of underwater cutting and diving ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com