Novel small-size duct turbofan engine

A turbofan engine, turbojet engine technology, applied in the direction of machine/engine, jet propulsion device, etc., can solve the problems of high technical difficulty and increased cost, and achieve the effects of low fuel consumption, simple structure and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

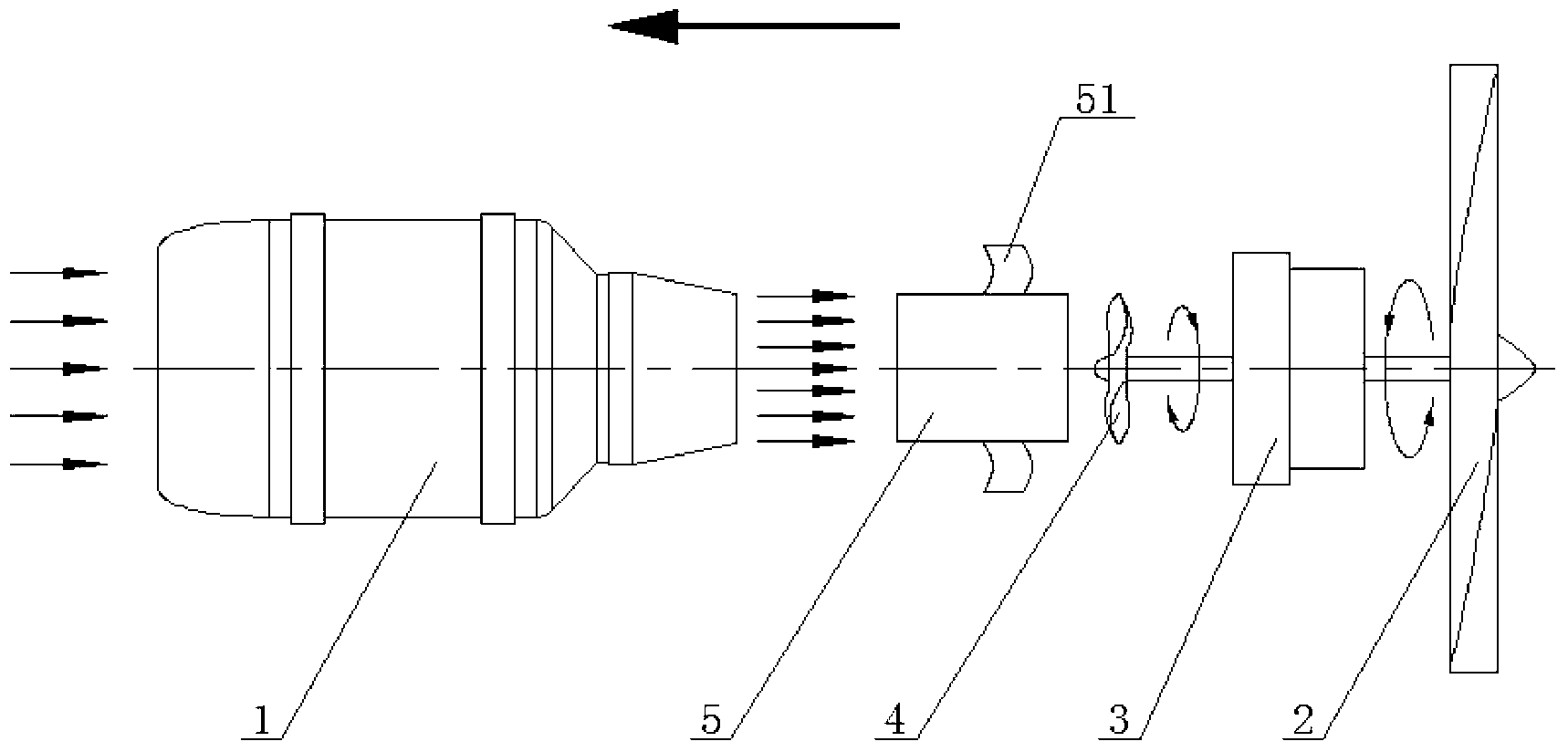

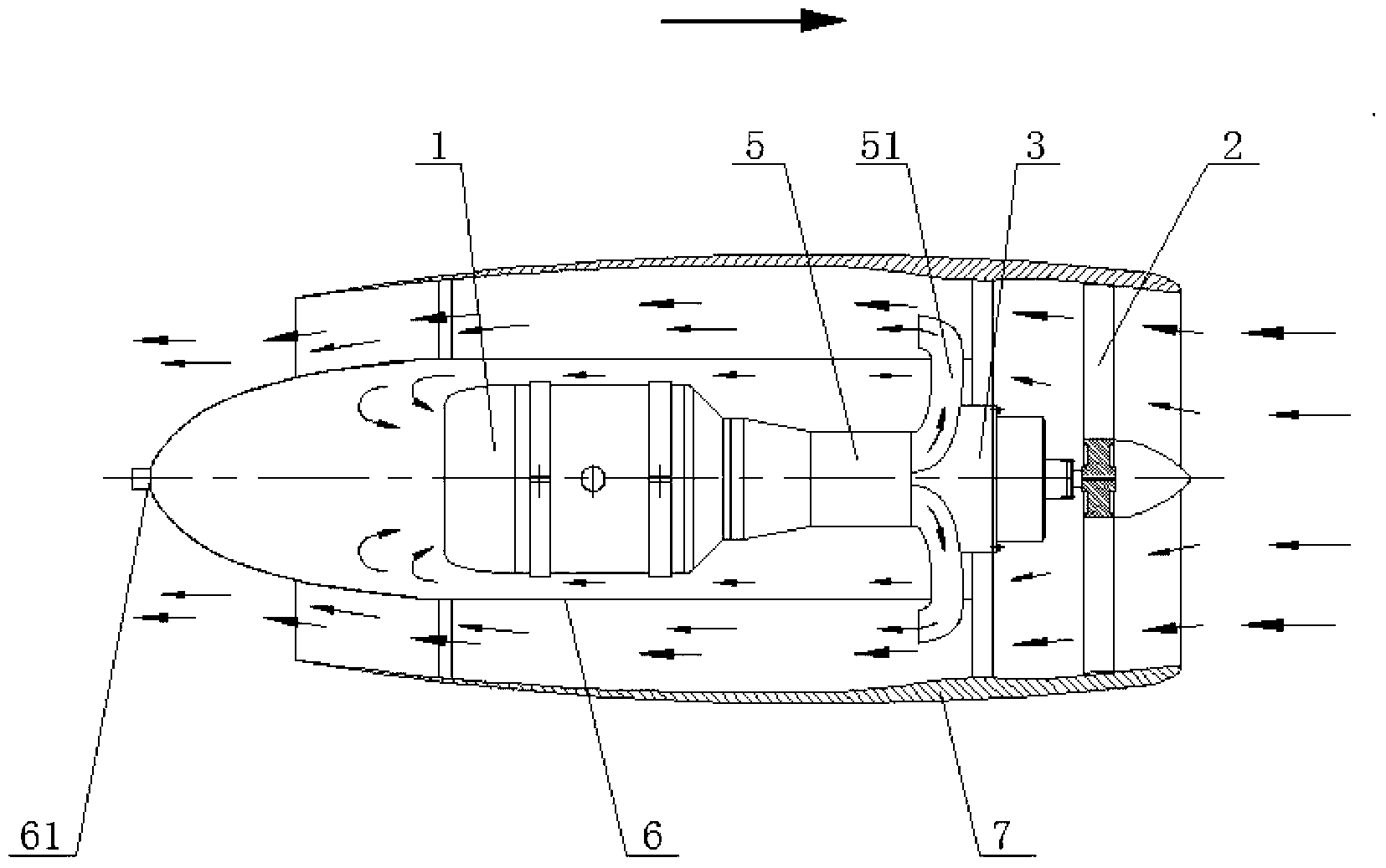

[0024] See figure 1 and figure 2 , the present invention has a turbojet engine 1 and a thrust fan 2; the thrust fan 2 is fixedly connected to the shaft at one end of the speed reducer 3, and a free turbine 4 is fixedly connected to the shaft at the other end of the speed reducer 3; the outer casing of the free turbine 4 A section of housing 5 is provided; one end of the housing 5 is airtightly connected with the airflow injection port of the turbojet engine 1, and the other end is airtightly connected with the end of the speed reducer 3 near the free turbine 4; the free turbine 4 The diameter is less than the diameter of the thrust fan 2; the outside of the turbojet engine 1 is provided with an engine intake guide cover 6, and the guide end of the engine intake guide cover 6 is provided with an engine intake air flow regulating hole 61; The air guiding cover 6, the speed reducer 3 and the thrust fan 2 are provided with an outer duct 7; the end of the casing 5 connected to th...

Embodiment 2)

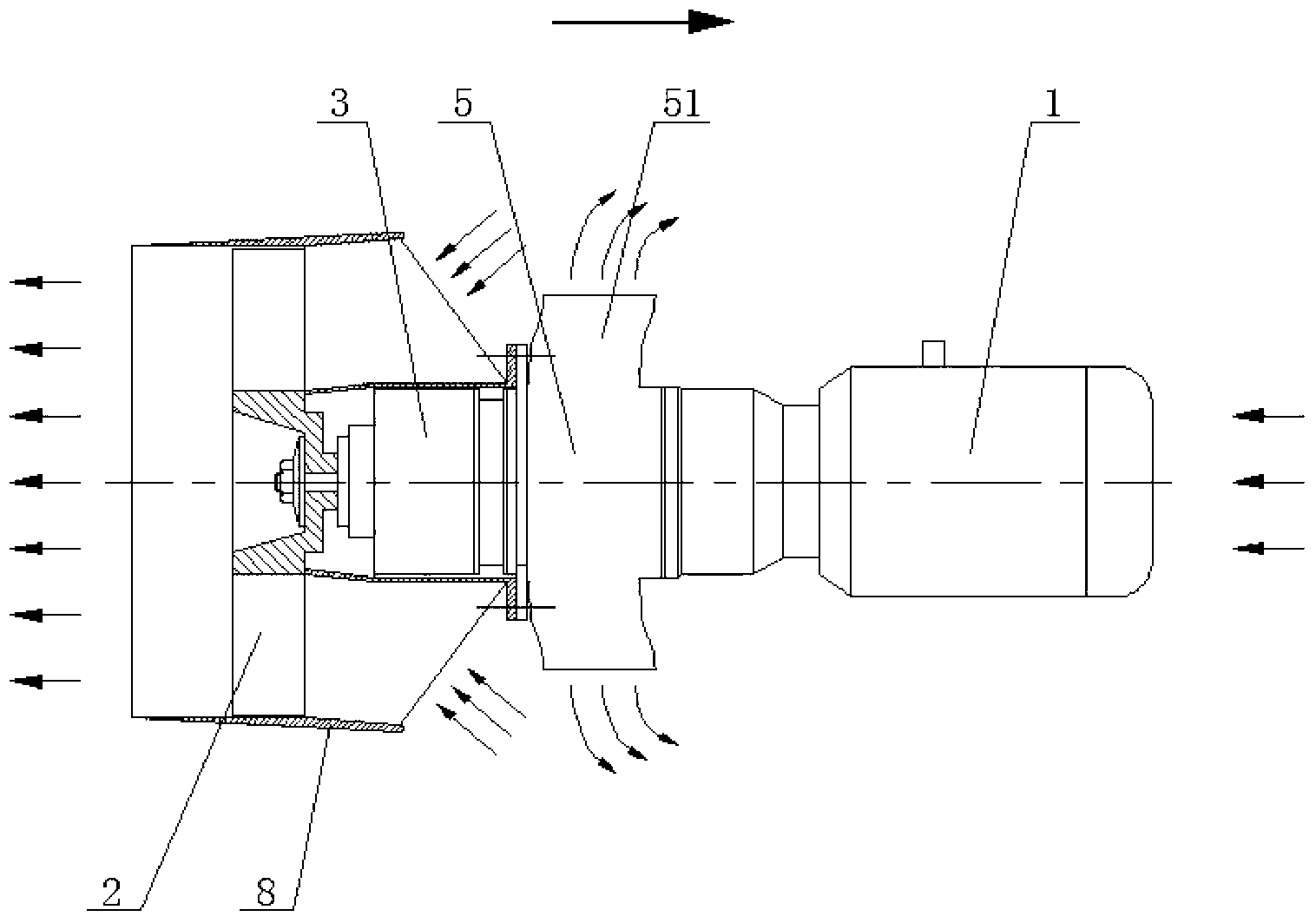

[0026] See figure 1 and image 3 , the present invention has a turbojet engine 1 and a thrust fan 2; the thrust fan 2 is fixedly connected to the shaft at one end of the speed reducer 3, and a free turbine 4 is fixedly connected to the shaft at the other end of the speed reducer 3; the outer casing of the free turbine 4 A section of housing 5 is provided; one end of the housing 5 is airtightly connected with the airflow injection port of the turbojet engine 1, and the other end is airtightly connected with the end of the speed reducer 3 near the free turbine 4; the free turbine 4 The diameter is smaller than that of the thrust fan 2; the reducer 3 and the thrust fan 2 are provided with a fan casing 8; the side of the casing 5 is evenly distributed with exhaust pipes 51.

[0027] Embodiment 1 and embodiment 2 all are to directly blow the free turbine 4 by the high-speed tail jet flow of the turbojet engine 1, so that the free turbine 4 rotates at a high speed, and the high-spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com