Inching gear engagement controlling device

A control device and inching technology, which is applied in the direction of transmission control, components with teeth, belts/chains/gears, etc., can solve the problems of end face cracking of meshing parts, "addendum teeth cannot be shifted, etc., and achieve reduction The number of gear shifts, preventing damage and other driving accidents, ensuring safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

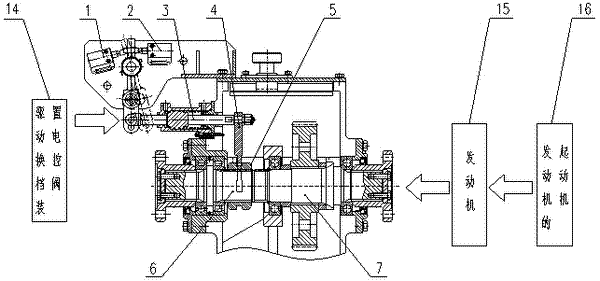

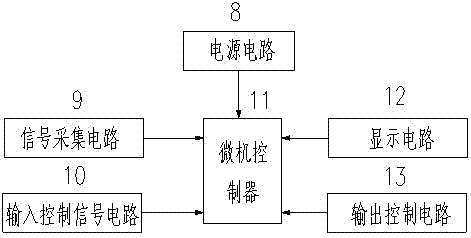

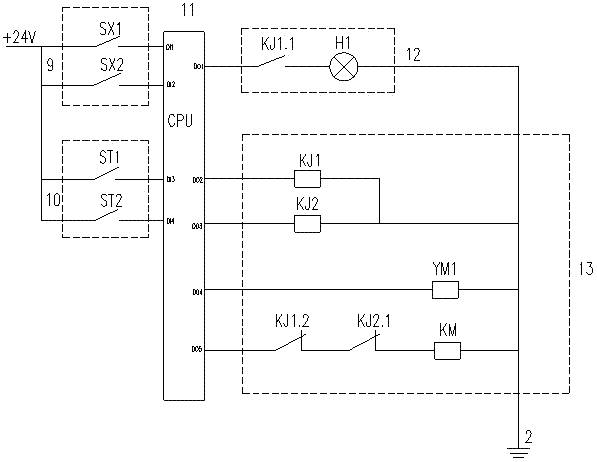

[0026] The present invention will be further described below in conjunction with the accompanying drawings and examples (sliding sleeve internal spline engagement transmission).

[0027] figure 1 , when the gear shifting fails, press the gear shifting switch ST1 on the operating console of the cab, and the electric control valve 14 (YM1) of the drive shifting device installed on the pneumatic pipeline is energized, and the electric control valve 14 (YM1) of the shifting device is driven ( YM1) Connect the pneumatic pipeline leading to the drive shifter 3, and the air flow pushes the drive shifter 3 to move in the direction of the input shaft 7, thereby driving the detachment fork 4 and the sliding sleeve at the front end of the drive shifter 3 5 to move in the direction of the input shaft 7 to perform the action of shifting gears. At this time, observe whether the shifting indicator light H1 on the operating console is on, if it is on, the shifting is successful; The starter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com