Double-auto-collimation optical system checking and regulating tube

An optical system and self-collimation technology, applied in the direction of optics, optical components, instruments, etc., can solve the problems of coverage pitch deviation, high cost, very strict environmental requirements, etc., to ensure stability and reliability, and eliminate external structural deformation , high stability and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

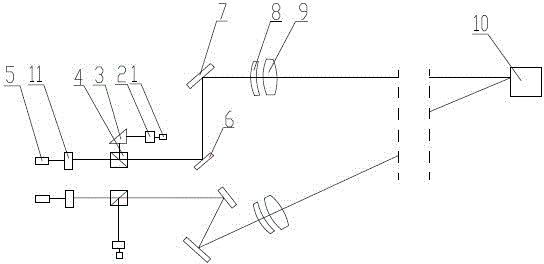

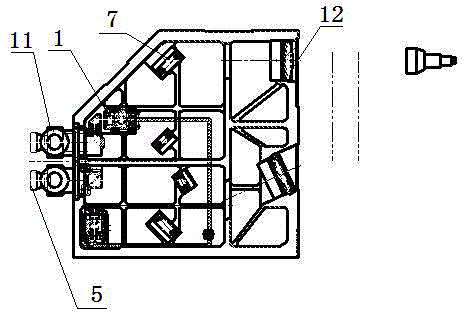

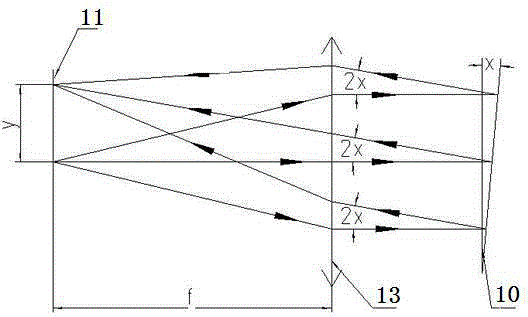

[0016] Such as figure 1 As shown, a double self-collimating optical system inspection tube includes a casing, and two self-collimating optical systems are arranged in the casing. The first self-collimation optical system and the second self-collimation optical system irradiate the light emitted by the light source onto the measured mirror 10 through the optical device respectively, and the first self-collimation optical system and the second self-collimation optical system The included angle formed by the two light rays emitted by the optical system is an acute angle, and the measured reflector 10 is located at the intersection of the two rays. If the reflective surface of the measured reflector is perpendicular to the incident light of the optical system, the light is still Backtrack.

[0017] Each self-collimating optical system includes a light source 1, a cross reticle 2, a first dichroic prism 4, a first mirror 6, a second mirror 7, a first objective lens 8, a second obj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com