Sub-aperture stitching-based high-accuracy planar optical element face type detection method

A technology of sub-aperture splicing and optical components, applied in the direction of optical devices, measuring devices, instruments, etc., can solve the problems of low precision of high-precision large-diameter planar optical components, and achieve the effect of an economical and effective detection method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

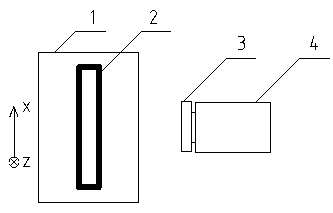

[0022] Embodiment 1: its structure is as figure 1 As shown, the device includes a two-dimensional (XZ) translation stage 1, a standard flat lens 3, a Fizeau type interferometer 4,

[0023] The standard plane lens 3 is fixed on the exit pupil of the Fizeau-type interferometer 4. At the same time, the plane optical element 2 is placed on the XZ translation stage 1, so that the position of the plane optical element 2 can be adjusted. The exit pupil of the small-aperture interferometer 4 is facing The plane optical element 2 adjusts the rotation of the XZ translation stage 1 in the X and Z directions, so that the plane optical element 2 is parallel to the standard plane lens 3, so as to measure the interference image.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com