A rim-driven reaction flywheel

A technology of reaction flywheel and wheel rim drive, which is applied in the direction of electric components, mechanical energy control, electrical components, etc. It can solve the problems of poor signal accuracy of position sensor and eddy current loss of flywheel, so as to improve mechanical efficiency, improve precision and high effective moment of inertia Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

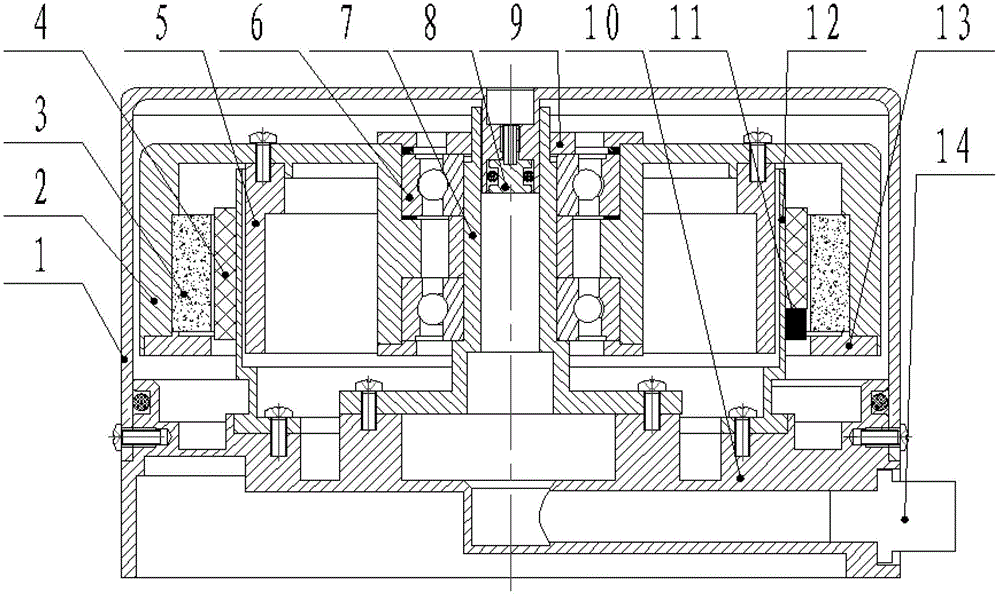

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

[0017] See attached figure 1 , the rim-driven reaction flywheel of the present invention is mainly composed of a static part and a rotating part, and the static part includes: a vacuum shell 1, a winding 4, an inner ring part of a bearing 6, a mounting shaft 7, a miniature vacuum valve 8, and a lock nut 9 , base 10, position sensor 11, armature support 12, circuit interface 14; Rotating part comprises: flywheel body 2, permanent magnet 3, inner magnetic ring 5, end magnetic ring 13, the outer ring part of bearing 6.

[0018] Both the winding 4 and the position sensor 11 are installed on the armature bracket 12, the position sensor 11 faces the permanent magnet 3, the winding 4 and the position sensor 11 are connected with the external control circuit through the circuit interface 14 and drive the rotating part of the flywheel Rotation; the rotating part of the flywhee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com