Temperature self-balancing overheating protection brushless direct current motor driver for bread maker

A brushless DC motor and overheating protection technology, which is applied in the direction of electronic commutator, single motor speed/torque control, etc., can solve the problems of low efficiency, low efficiency of AC motor, large electromagnetic noise, etc., and achieve simple circuit and structure Effects of compactness, improved safety and applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

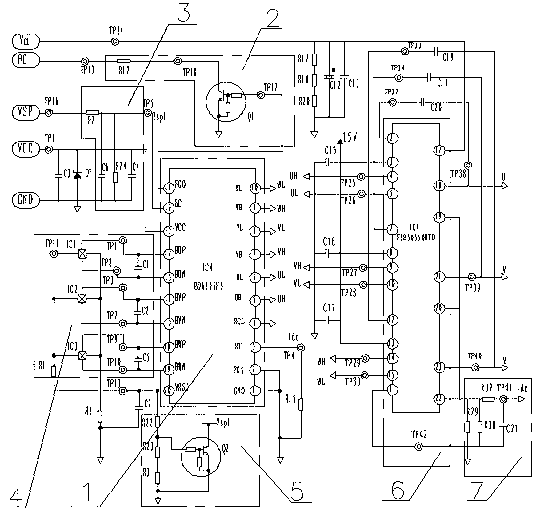

[0017] Attached below figure 1 The present invention is described further:

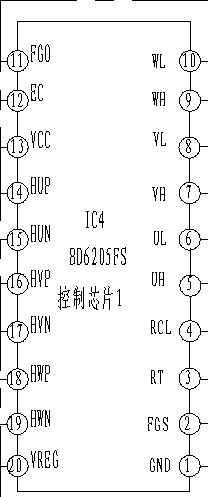

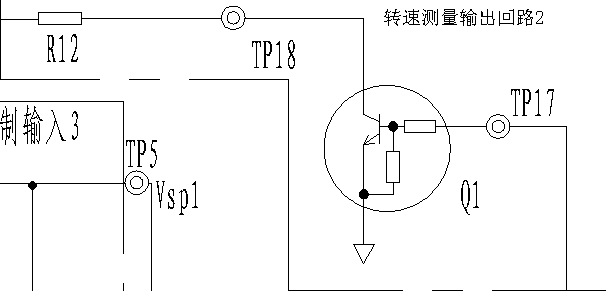

[0018] A temperature self-balancing overheat protection brushless DC motor driver for a bread machine, comprising: a control chip 1, a rotational speed measurement output circuit 2, a rotational speed control input circuit 3, a Hall rotor position sensor detection circuit 4, a temperature measurement circuit 5, and an IPM power Module circuit 6, over-current detection circuit 7, because the bread machine needs low speed and high torque, so the control chip 1 we choose the 120-degree hardware drive control chip produced by ROHM Company and adopts the upper arm PWM control mode. In order to reduce the switching noise, its oscillation The frequency is set to 20KHz, and the speed control voltage varies within the range of 1.7V to 6.0V. When the speed control voltage is 6.0V, the corresponding PWM duty cycle is MAX95%, and the speed control voltage MIN is 1.7V to 2.5V, which is lower than The motor stops ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com