Hard surface liquid cleaner composition

A technology for liquid cleaners and hard surfaces, applied in the direction of surface-active detergent compositions, detergent compositions, anionic surface-active compounds, etc., can solve the problem of no technical inspiration, no disclosure of lipophilic physical properties, cooking Achieves excellent storage stability, excellent cleanability, and high cleaning power without disclosing issues such as oil stain removability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

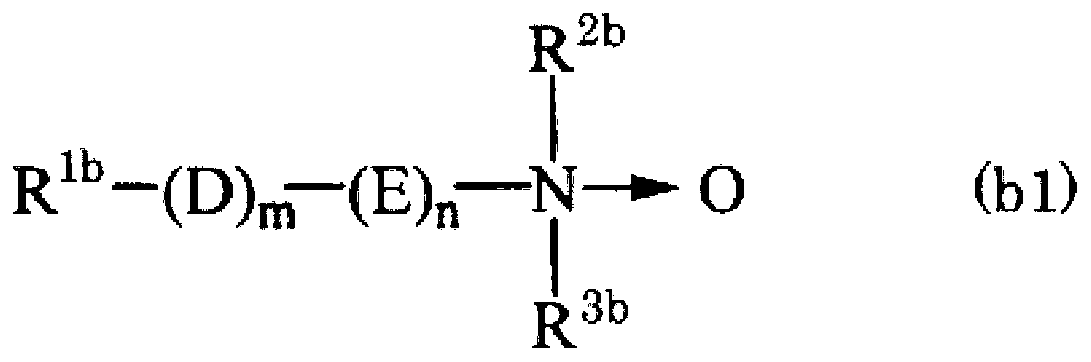

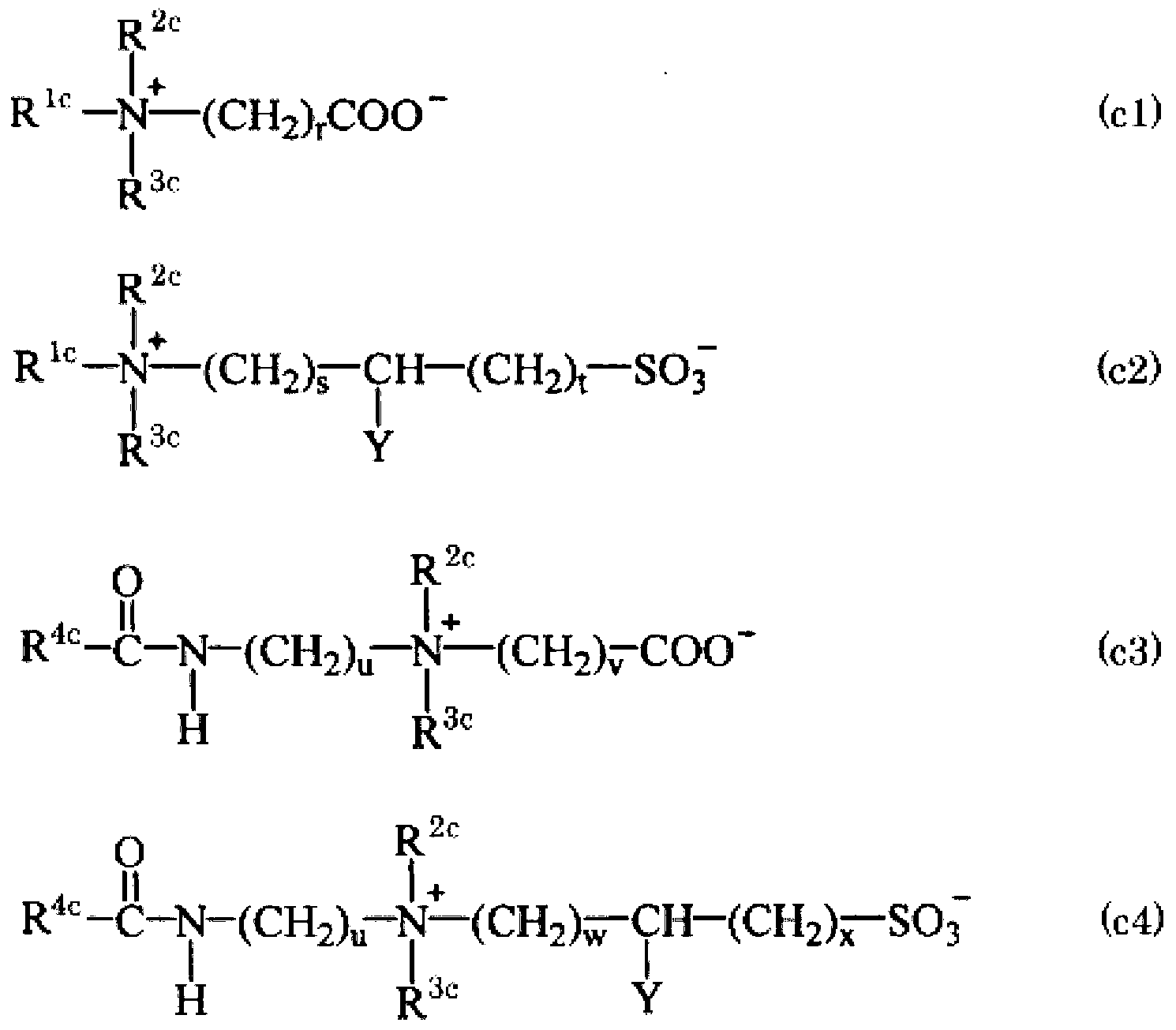

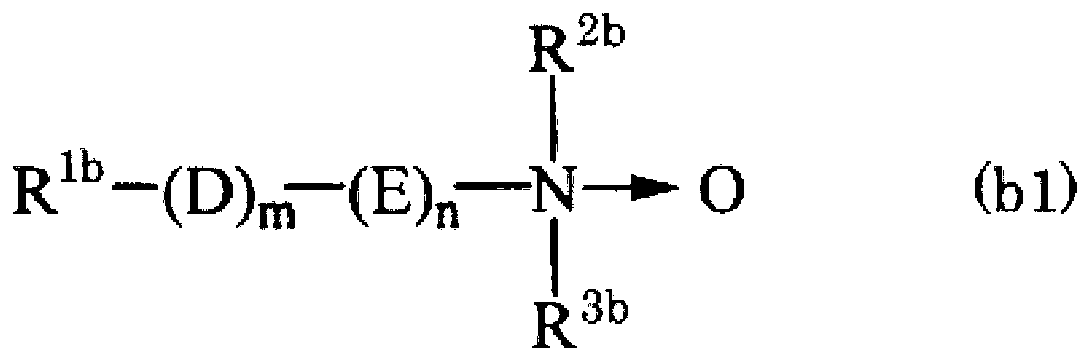

Method used

Image

Examples

Embodiment 1~14

[0107] Examples 1-14, Comparative Examples 1-16

[0108] Hereinafter, embodiments of the present invention will be further described and disclosed through examples. The examples described above are merely illustrative of the present invention, and are not intended to be limiting in any way. Using each component shown in the following table|surface, each liquid cleaning composition for hard surfaces of an Example and a comparative example was obtained. The numerical value of the amount of each component in a table|surface is mass %, and the balance is deionized water. The values of the mass ratios of the components in the table are described with the denominator ( / 1) omitted.

[0109] Each of the prepared compositions of Examples and Comparative Examples 1 to 4, 6, and 8 to 16 existed as a homogeneous liquid phase without turbidity or separation. On the other hand, each composition of Comparative Examples 5 and 7 could not be made into a homogeneous liquid composition and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com