Device for undoing textile fiber bundles

A technology of fiber bundles and textiles, applied in the field of devices, can solve problems such as failure to meet requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

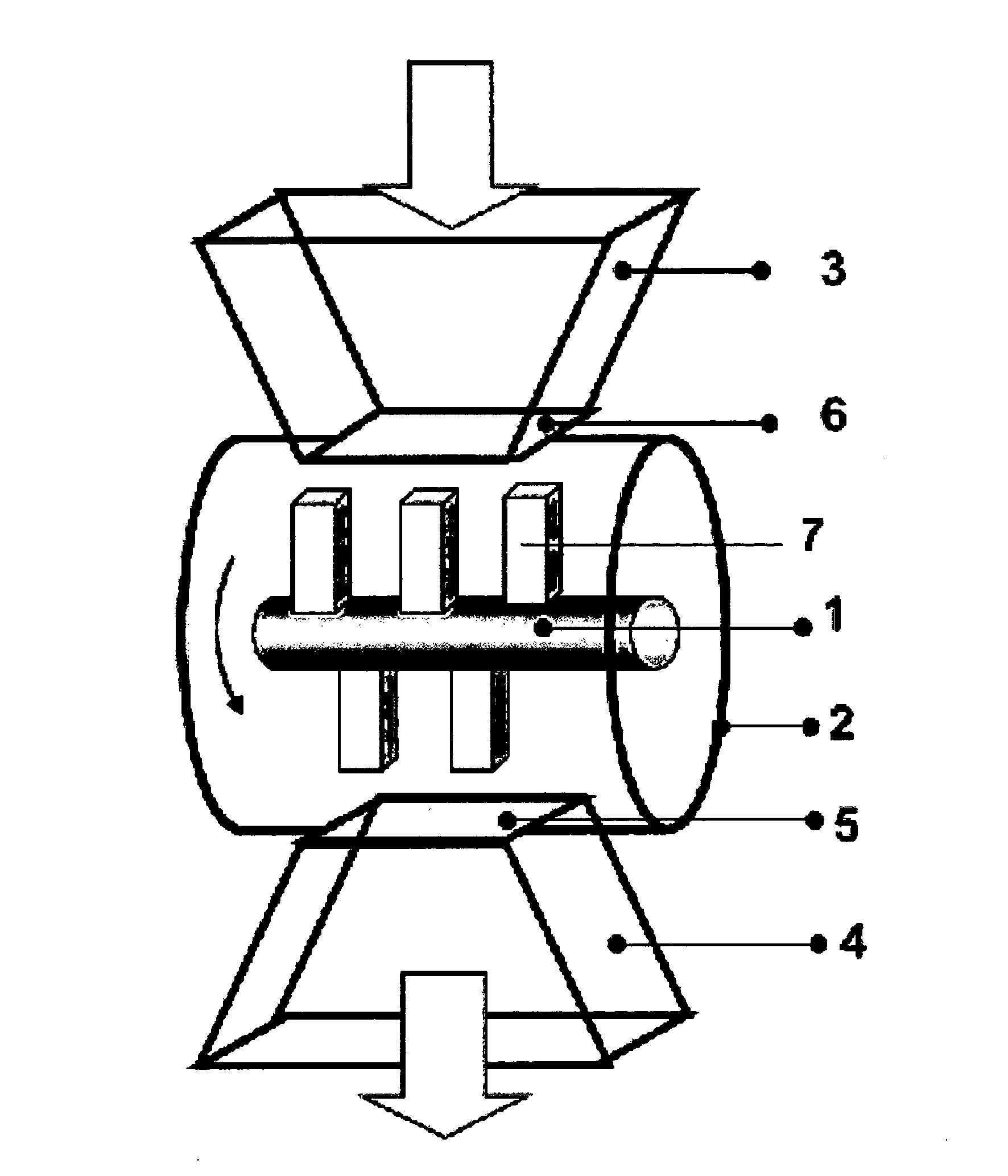

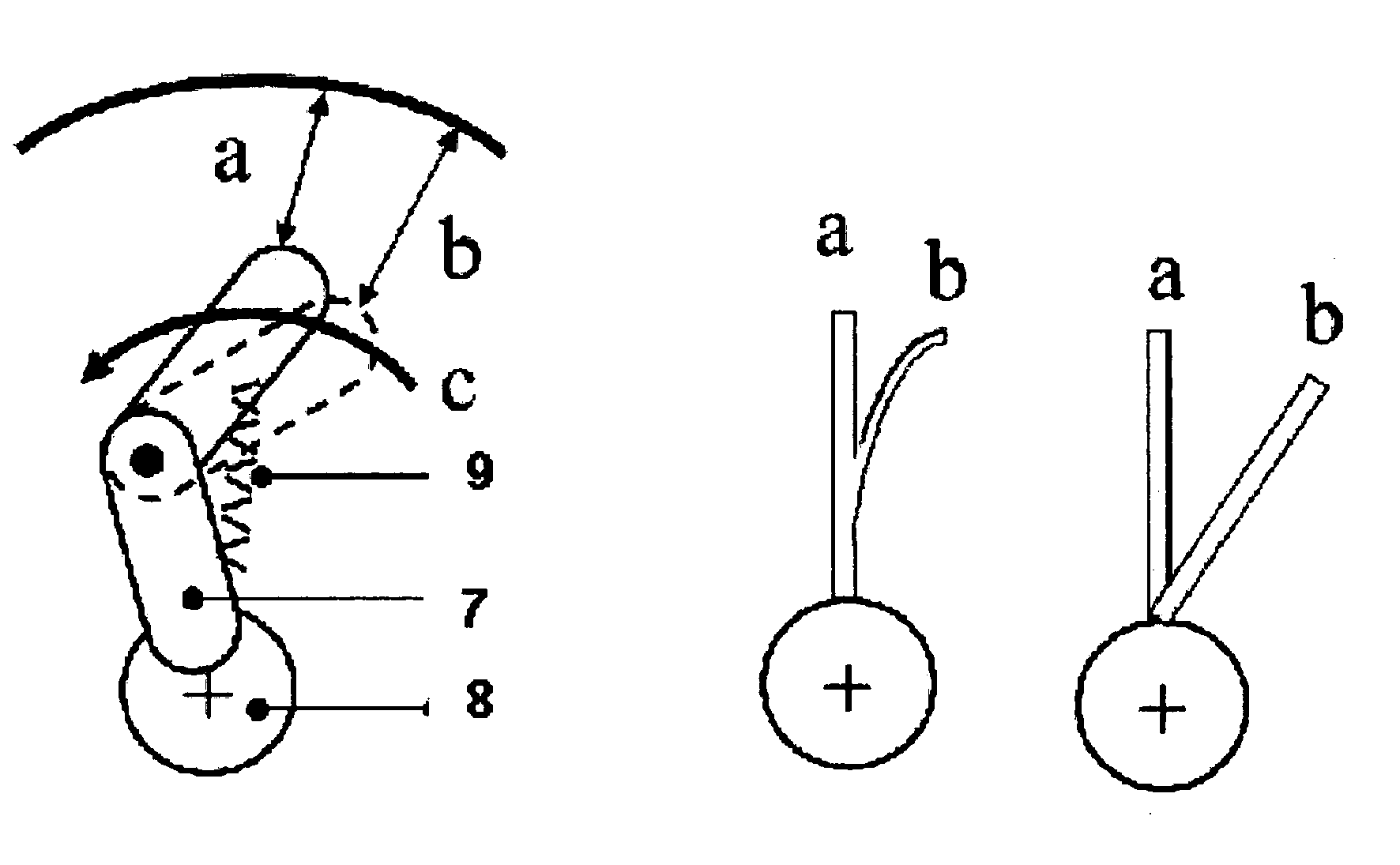

Embodiment 1

[0034] 250g, 40mm long, long cut polyamide yarn of fineness 336 is processed in an orifice device with 5mm aperture for 15 seconds, as figure 1 shown. The rotor with 4x8 impingement blades spins at 1000 rpm. use figure 2 The two-part flap-type blade shown in can protect the material very well, and due to the high peripheral speed, no spring parts that return by spring force are used. The non-active zone volume accounts for 40%. The device produces a mixture of single fibers and separated fiber bundles, which are then processed and carded into a needle felt, which can form a uniform nonwoven fabric compared to unprocessed long yarns. After the material storage chamber is full, the charging cover is opened for 2 seconds to feed, and after processing, the discharge port cover is opened for 2 seconds to completely empty the processing chamber, and the material enters the pneumatic suction pipe.

Embodiment 2

[0036] Basalt fiber bundles with a length of 50 mm and a single mass of 0.00537 g are used as bulk materials with a bulk density of 200 kg / m3. The feeding amount of this kind of material is 300g, in such as figure 1 Processed for 12 seconds in the apparatus shown fitted with a 5 mm aperture mesh floor. Compared with Example 1, a smaller number of blades can be used, and the non-active area reaches 60%. The blade rotating speed adopts 750 revs / min, and the product is a single fiber and separated fiber bundles stirred together, and the bulk density is 26kg / m3. The conditions for longitudinal separation of fiber bundles into partial fiber bundles and single fibers depend on the bulkiness of the material.

Embodiment 3

[0038] 300g is about 16cm sutured with glass wool 2 to 25cm2 Sheet-shaped unidirectional carbon fiber fabric, the maximum edge length is figure 1 In the device shown in , the blade speed is 1200 / min, and the processing is carried out for 6 seconds. use figure 2 The folding leaf shown in does not require the use of additional return spring components. The non-active area is 50%. In order to improve the separation effect of fiber bundles, four stacking parts of 5mm protruding into the non-active area, parallel to the impingement blade rotation axis and at the same distance from each other are used around the stator cover. The stacking part has a cuboidal structure and its length corresponds to the width of the stirrer. Mixtures of individual carbon fibers and carbon fiber bundles consist of varying amounts of individual fibers, sewing yarns and fiber materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com