Mounting structure for circuit component and method for mounting circuit component

A technology of circuit components and mounting structures, which is applied to electrical components, printed circuits, printed circuits, etc., and can solve problems such as large vibration of circuit components and easy vibration of circuit components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

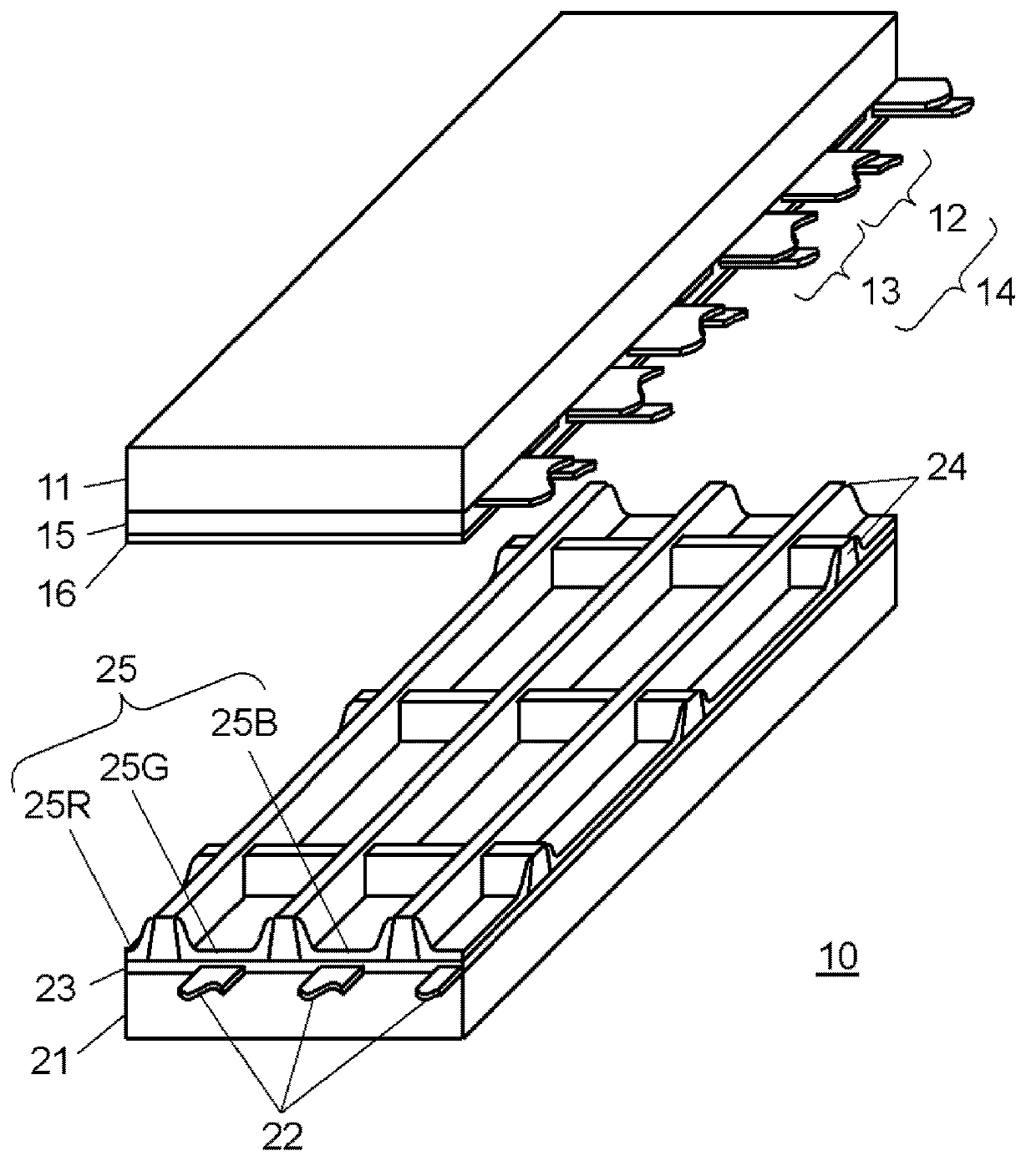

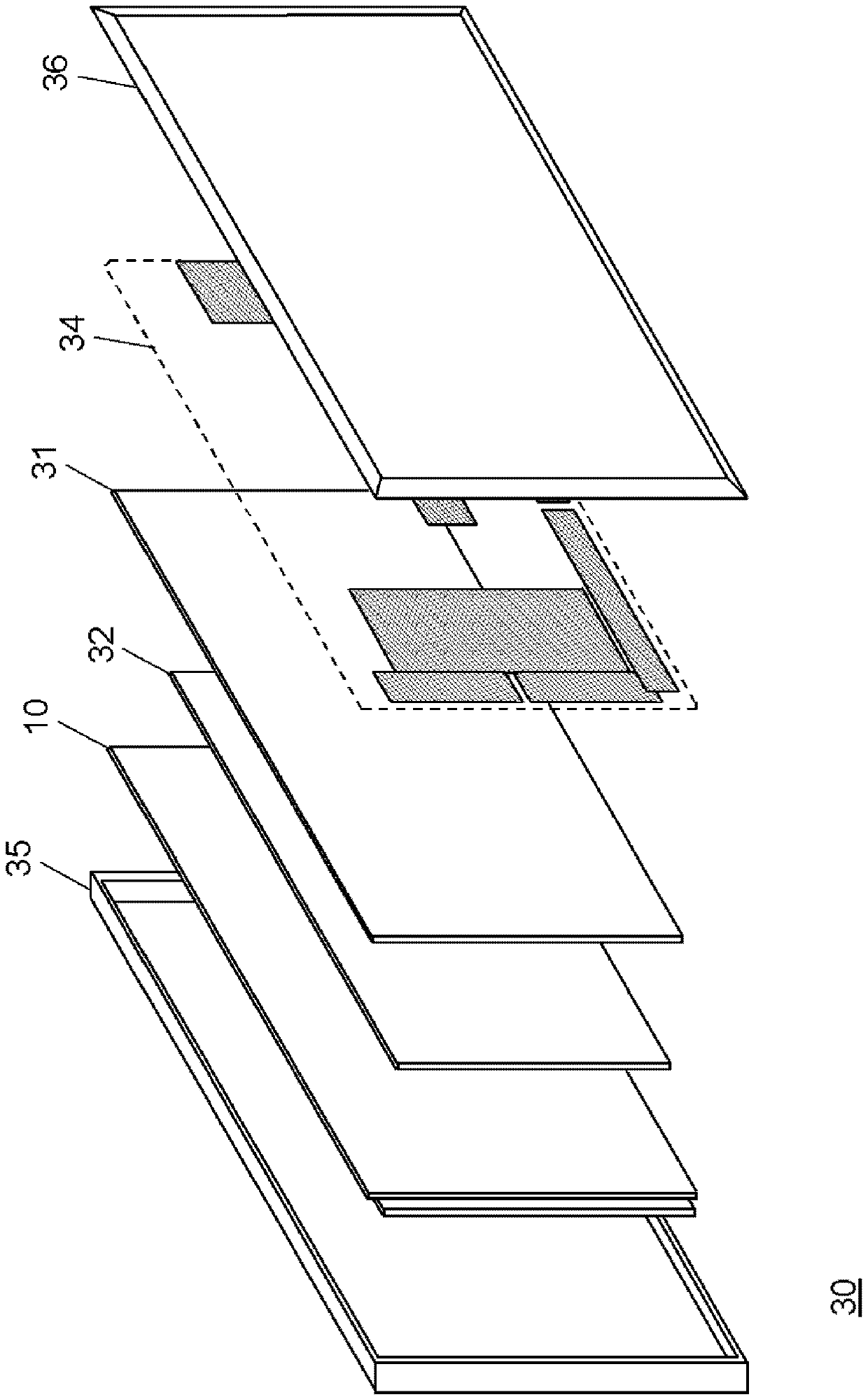

[0041] figure 1 It is an exploded perspective view showing the configuration of panel 10 employed in the plasma display device according to Embodiment 1 of the present invention.

[0042] A plurality of display electrode pairs 14 including scan electrodes 12 and sustain electrodes 13 are formed on front substrate 11 made of glass. Furthermore, dielectric layer 15 is formed so as to cover scan electrodes 12 and sustain electrodes 13 , and protective layer 16 is formed on dielectric layer 15 .

[0043]The protective layer 16 is effective as a panel material in order to reduce the discharge start voltage in the discharge cell, and has a large secondary electron emission coefficient and excellent durability when neon (Ne) and xenon (Xe) gases are enclosed. Made of a material mainly composed of magnesium oxide (MgO).

[0044] The protective layer 16 may consist of one layer, or may consist of several layers. In addition, a structure in which particles exist on a layer may be use...

Embodiment approach 2

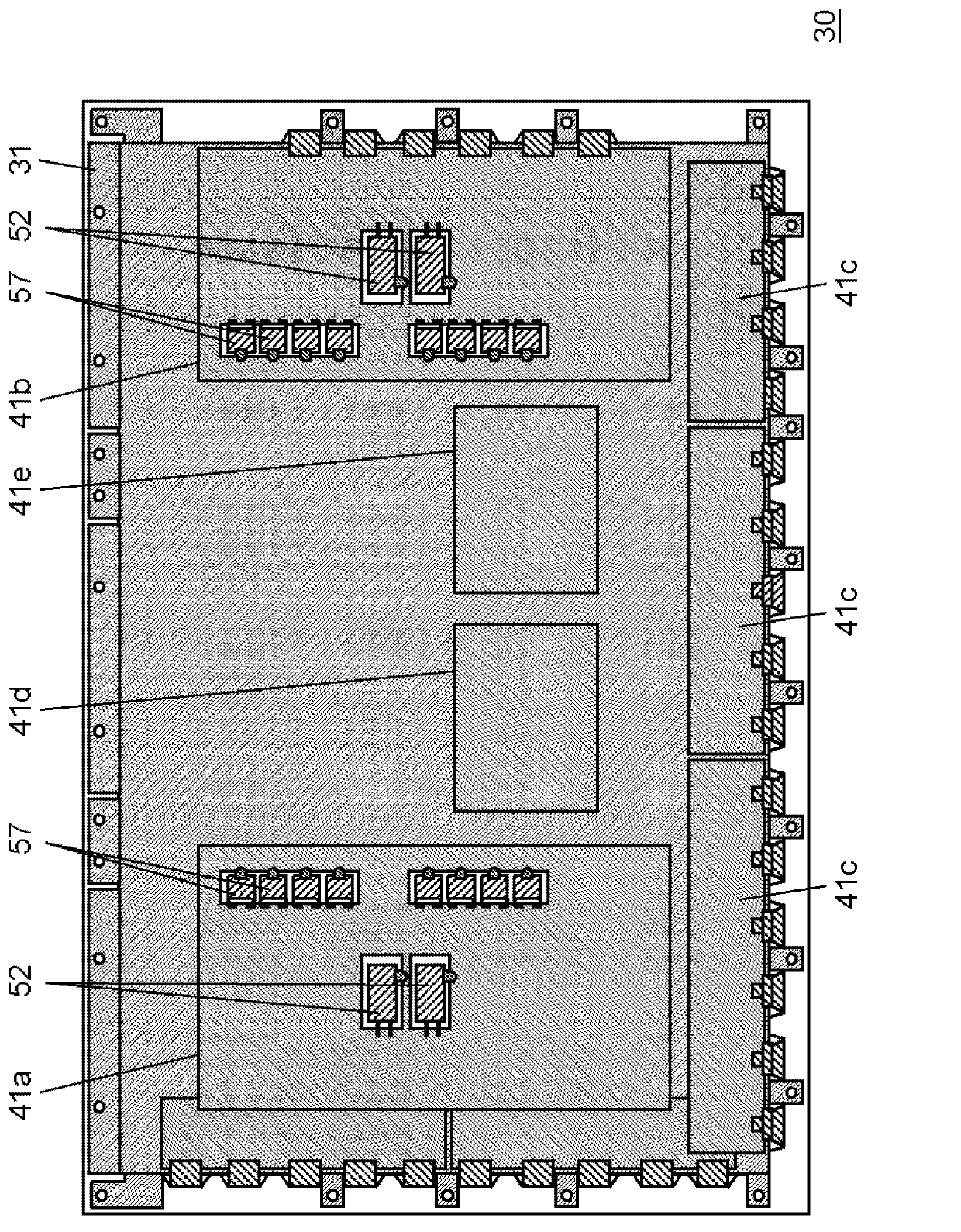

[0092] Figure 5A It is a plan view showing an example of hole portion 42 provided in circuit board 41 of plasma display device 30 according to Embodiment 2 of the present invention.

[0093] Figure 5B It is a plan view schematically showing an example of a mounting structure in which electrolytic capacitor 52 is mounted on circuit board 41 of plasma display device 30 in Embodiment 2 of the present invention.

[0094] Such as Figure 5A As shown, the circuit board 41 has a hole 42 , a through hole 43 , and a protrusion 45 .

[0095] The hole portion 42 is provided in the circuit board 41 to have a size larger than the external size of the main body portion 52 a excluding the lead wire 53 of the electrolytic capacitor 52 mounted on the circuit board 41 .

[0096] A through-hole 43 is provided in the circuit board 41 for insertion of the lead wire 53 of the electrolytic capacitor 52 .

[0097] The convex part 45 is provided on one side of the hole part 42, and has a shape w...

Embodiment approach 3

[0111] Figure 6A It is a plan view showing an example of notch portion 62 provided in circuit board 61 of plasma display device 30 in Embodiment 3 of the present invention.

[0112] Figure 6B It is a plan view schematically showing an example of a mounting structure in which electrolytic capacitor 52 is mounted on circuit board 61 of plasma display device 30 in Embodiment 3 of the present invention.

[0113] Such as Figure 6A As shown, in Embodiment 3, the circuit board 61 has the notch 62 , the through hole 63 , and the protrusion 64 .

[0114] At the corners of the circuit board 61 , cutouts 62 are provided on the circuit board 41 with dimensions larger than the external dimensions of the main body portion 52 a of the electrolytic capacitor 52 mounted on the circuit board 61 except the lead wire 53 .

[0115] In addition, although the four sides of the hole 42 shown in Embodiment 1 and Embodiment 2 are blocked by the circuit board 41, since the notch 62 in this embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com