Valve ball loading device of an automatic ball valve assembling machine

An automatic assembly machine and valve ball technology, applied in the field of machinery, can solve the problems of not recruiting enough workers for assembly and production, large labor costs, low economic benefits, etc., and achieve the effects of ingenious design, high positioning accuracy and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

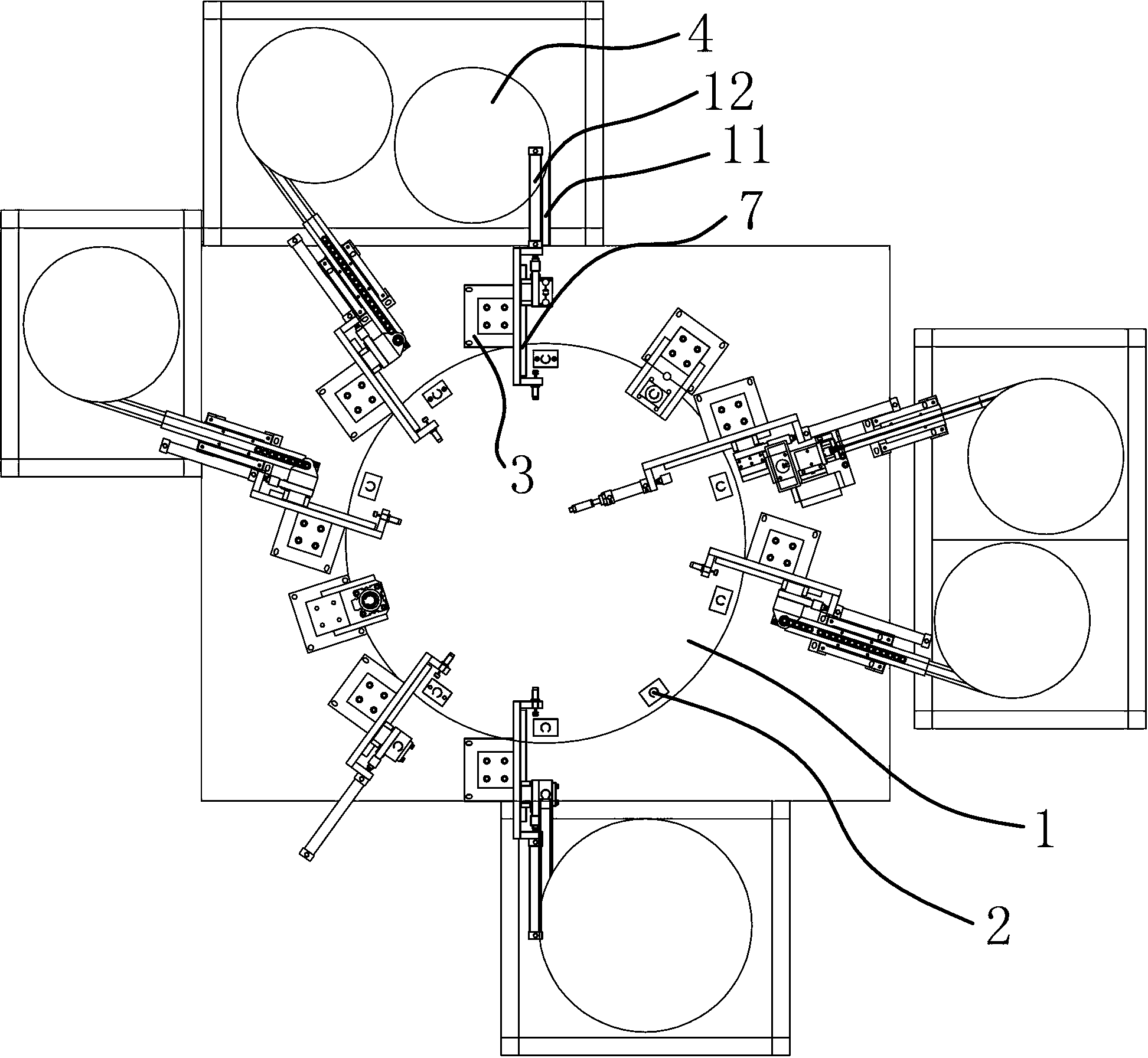

[0029] Such as figure 1 As shown, the valve ball loading device is a part of the ball valve automatic assembly machine. The assembly machine includes a disc-shaped worktable 1 that can rotate around its axis. The workbench 1 is equipped with ten molds at equal intervals along its circumference The base 2 and the die base 2 are fixed on the workbench 1 by bolts. The die base 2 has a fixing groove for fixing the valve body. The valve ball loading device is located on the side of the workbench 1.

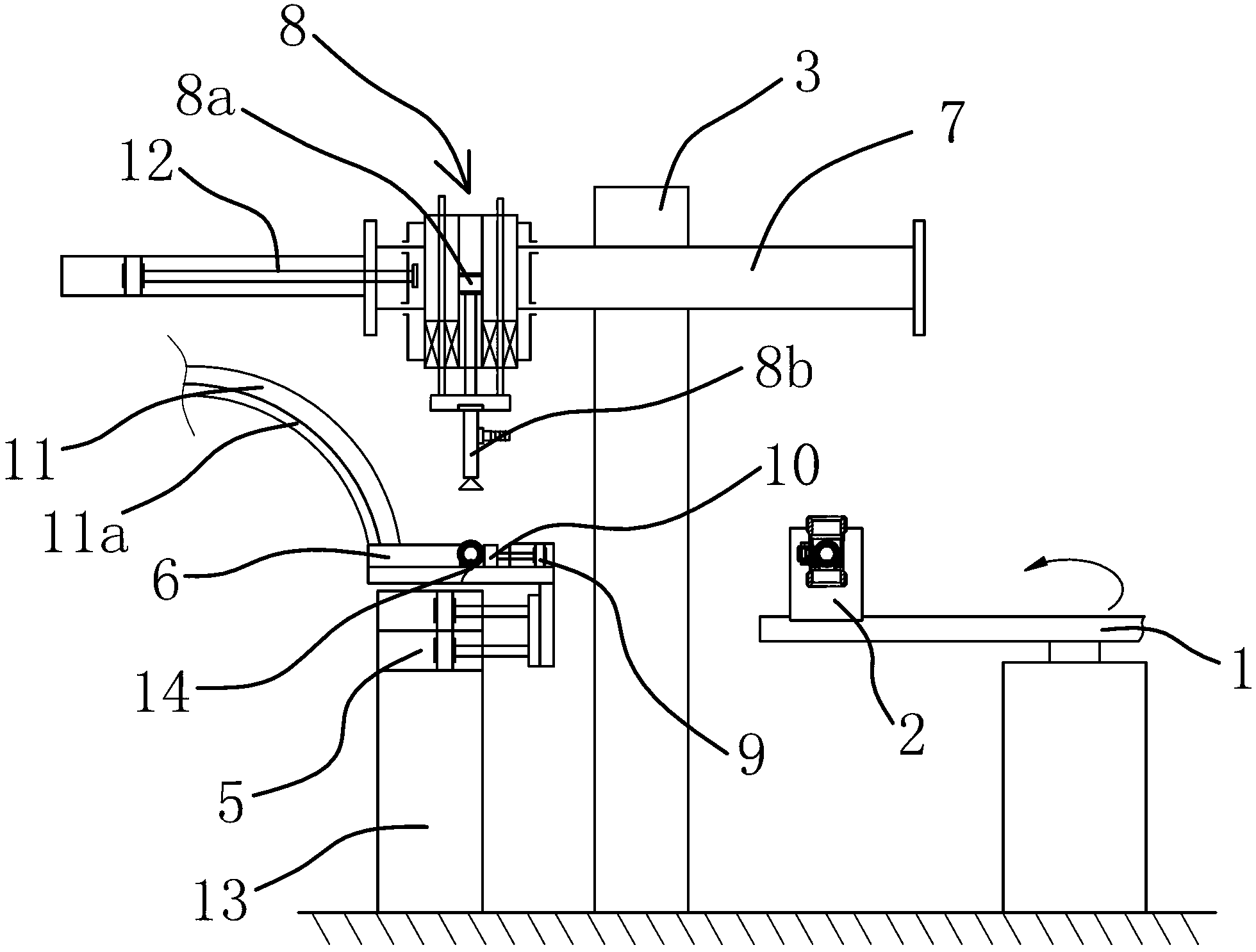

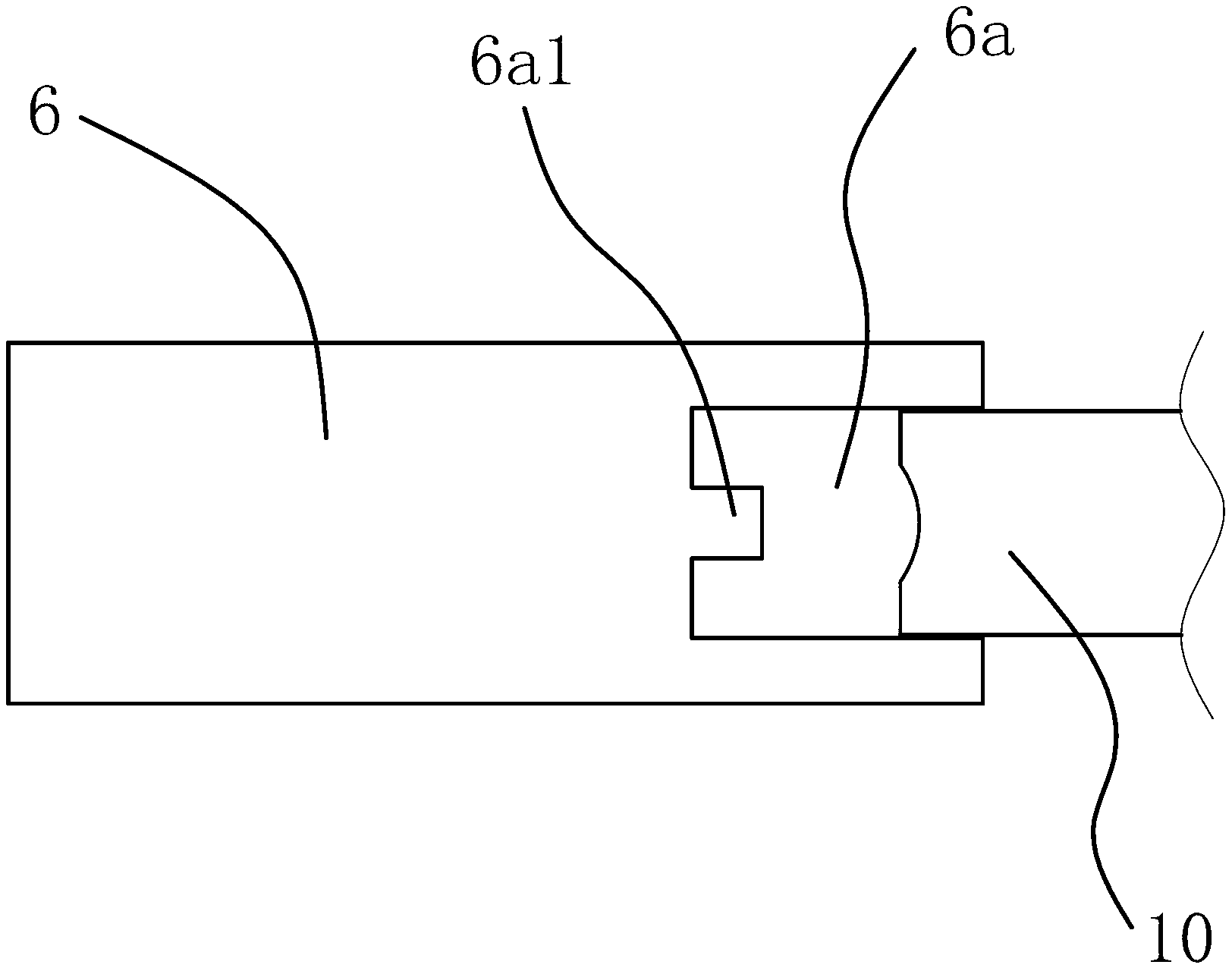

[0030] Such as figure 2 As shown, the valve ball loading device includes a support 3, a vibrating tray 4, a slide cylinder 5, a clamping cylinder 9, a positioning bar 6, a mounting frame 13, a detector 14 and an arc feeder 11.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com