Hydroxyalkyl cellulose

A technology of hydroxyalkyl cellulose and solid preparations, which is applied in the field of hydroxyalkyl cellulose, can solve the problems of reduced binding force and lower drug layering efficiency, achieve sufficient tablet strength, good disintegration time, and improve drug quality. The effect of stacking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

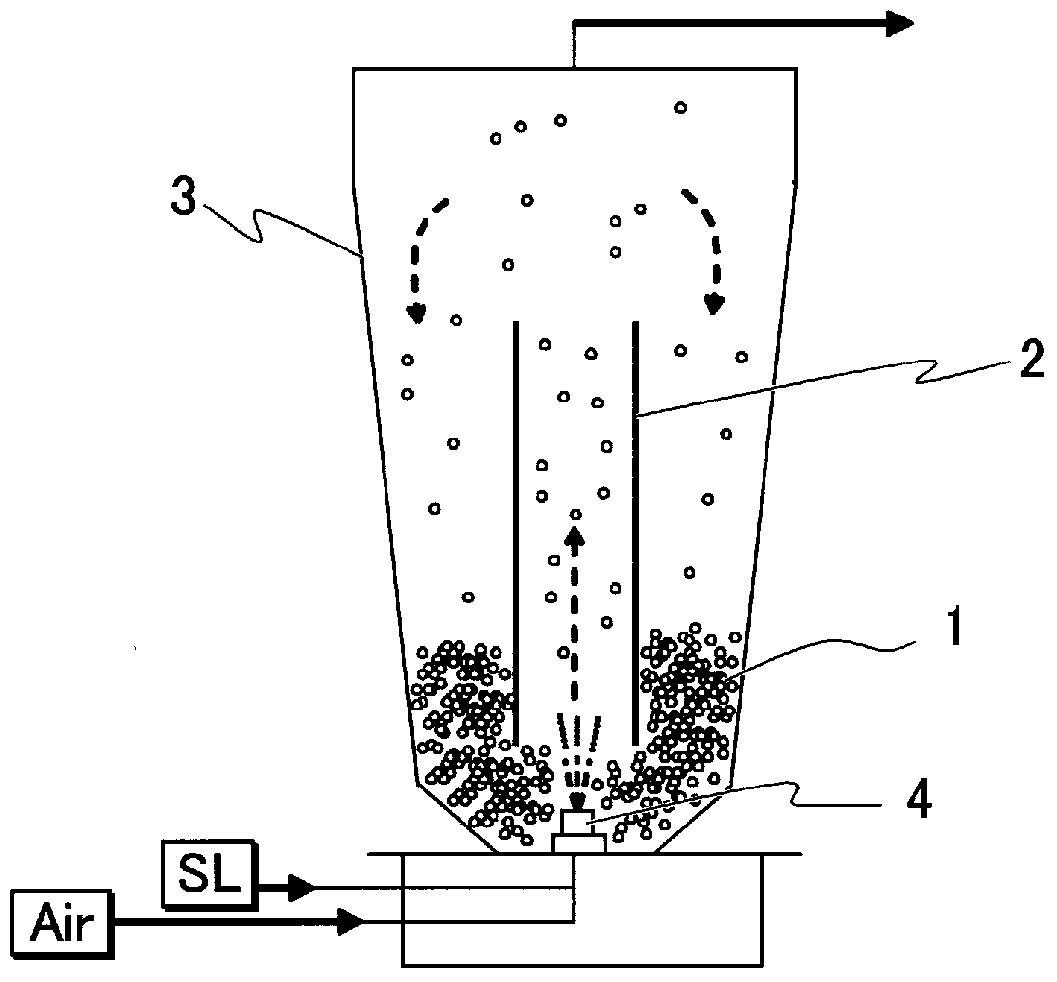

Method used

Image

Examples

Embodiment 1

[0096] Hydroxypropyl cellulose having a viscosity of 2.2 mPa·s in a 2% concentration aqueous solution at 20° C. was dissolved in water at a concentration of 15%. The aqueous solution was heated to about 62°C. Part of the hydroxypropyl cellulose was gelled and precipitated. Aliquot the supernatant. Dilute the supernatant with water to obtain a 2% aqueous solution of hydroxypropyl cellulose. The viscosity at 20°C was 1.70 mPa·s. Water was removed from the above supernatant to obtain hydroxypropylcellulose.

Embodiment 2

[0098] By the same method as in Example 1 except that the heating temperature was changed to 58° C., hydroxypropyl cellulose having a viscosity of 1.84 mPa·s in a 2% aqueous solution at 20° C. was obtained.

Embodiment 3

[0100] By the same method as in Example 1 except that the heating temperature was changed to 55° C., hydroxypropyl cellulose having a viscosity of 1.93 mPa·s in a 2% aqueous solution at 20° C. was obtained.

[0101] Evaluation of the coated particles was carried out in the following manner.

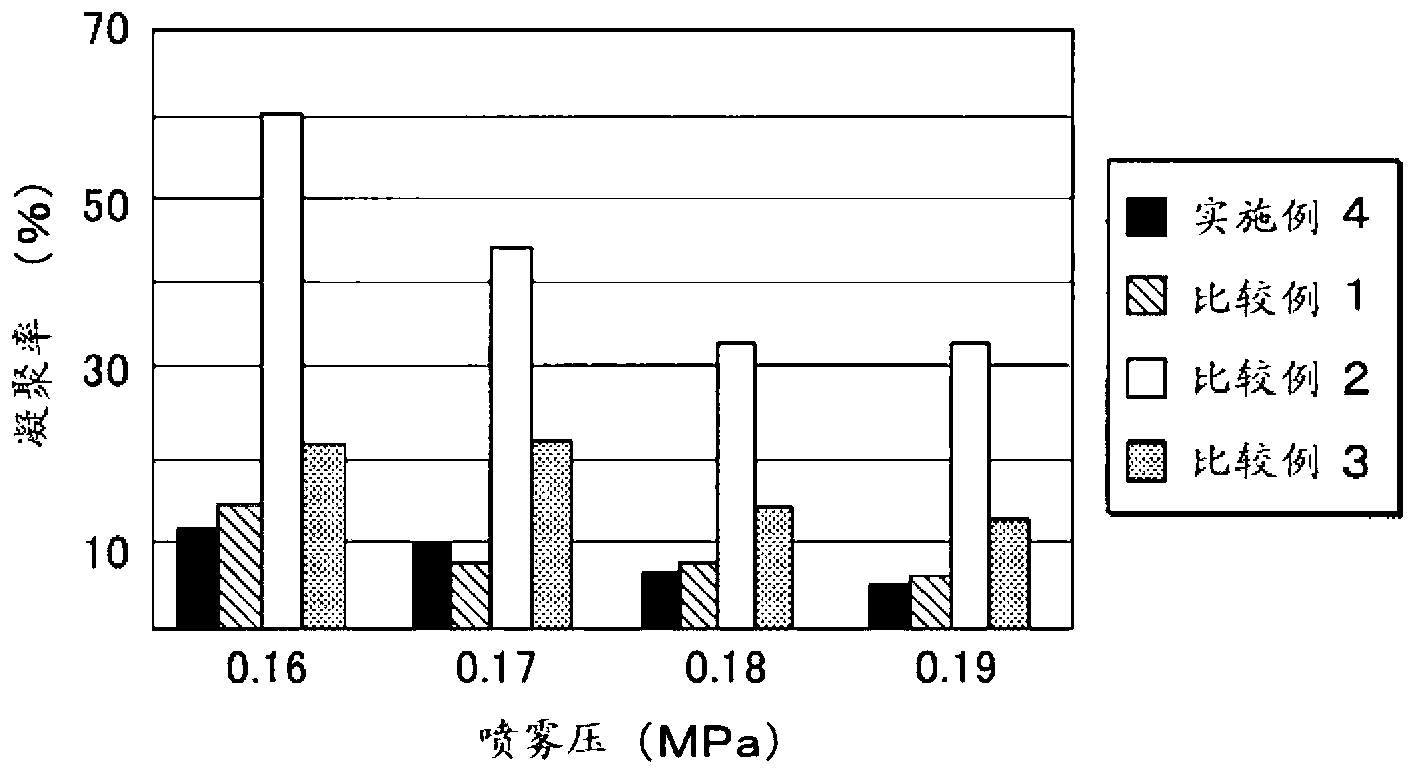

[0102] (agglomeration rate)

[0103] The particle size distribution of the CCSS-coated particles was measured using an electromagnetic shaker (manufactured by Tsutsui Chemical Instruments Co., Ltd., sample input amount: 1 g). Particles in each portion were observed with a digital microscope, and as a result, the portion above the inflection point in the log-normal probability graph of the cumulative % under sieve was confirmed to be an aggregate. Therefore, the ratio of the amount of particles sieved above the inflection point to the total amount of particles was set as the aggregation rate.

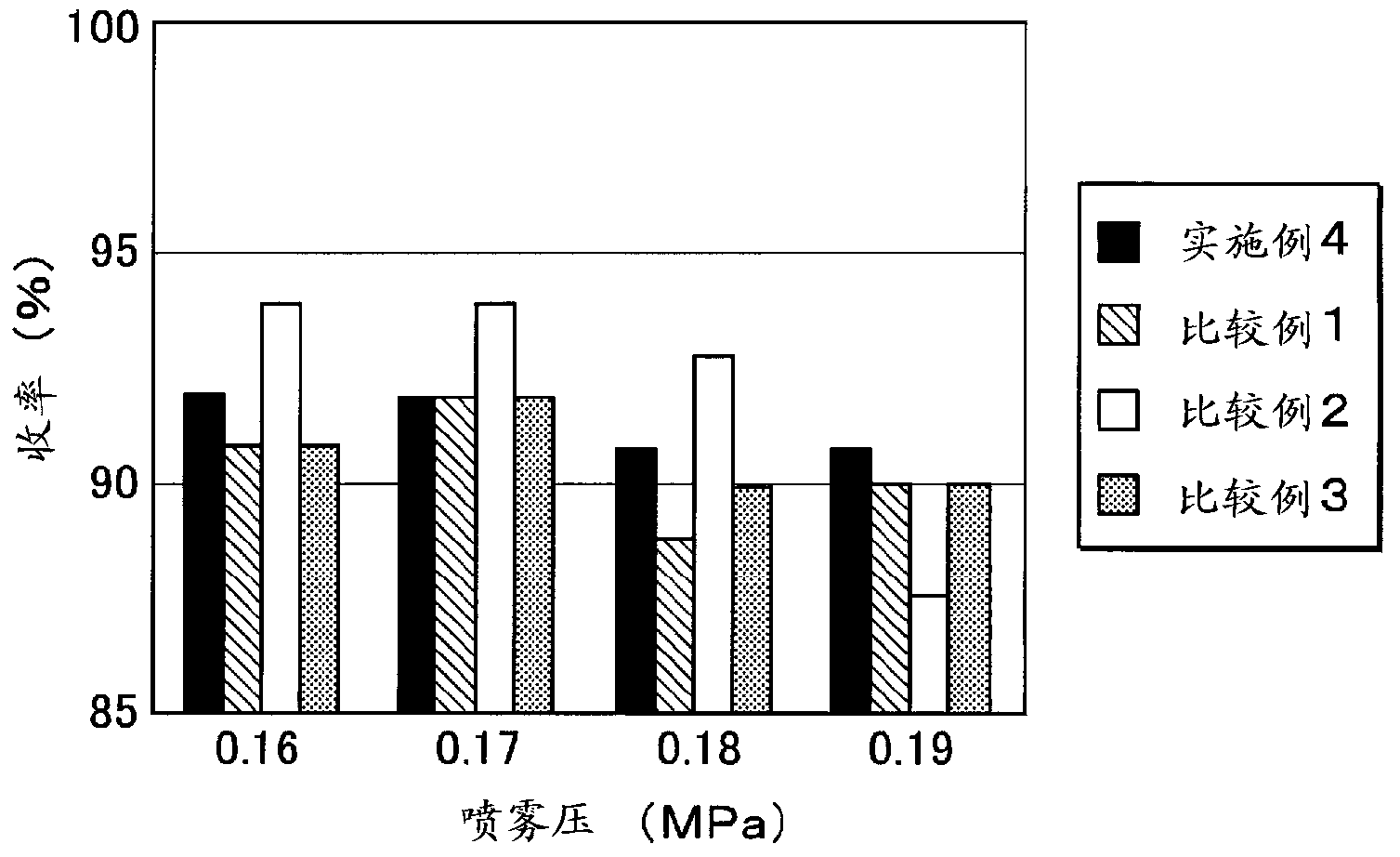

[0104] (drug layering efficiency)

[0105]10 mg of the CCSS-coated particles were placed in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com