Fire tube type heating device applied to flue-cured tobacco three-dimensional seedling raising greenhouse

A three-dimensional seedling and flue-cured tobacco technology, applied in the field of crop greenhouses, can solve the problems of high input and operating costs, and inconspicuous warming effects, and achieve the effects of reduced use costs, reduced heat energy consumption, and flexible deployment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

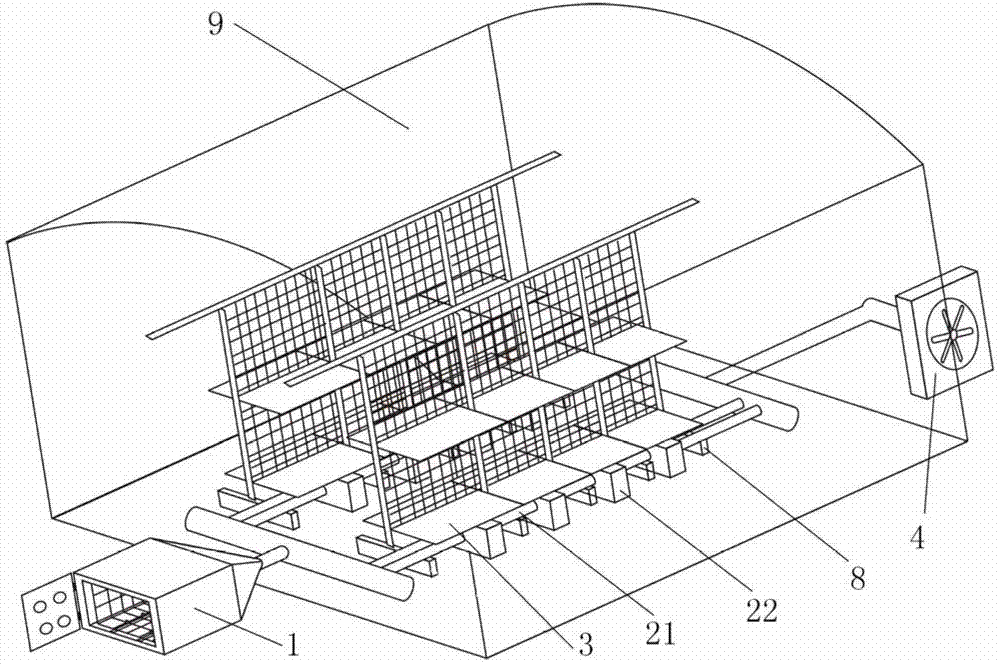

[0030] Such as figure 1 As shown, the warming equipment is made up of stove 1, radiator and drainage fan 4; radiator is arranged on the bottom of tobacco seedling tray support 3 in the greenhouse, and its hot gas inlet is communicated with the smoke outlet 11 of stove 1 through pipeline; The drainage fan 4 is connected.

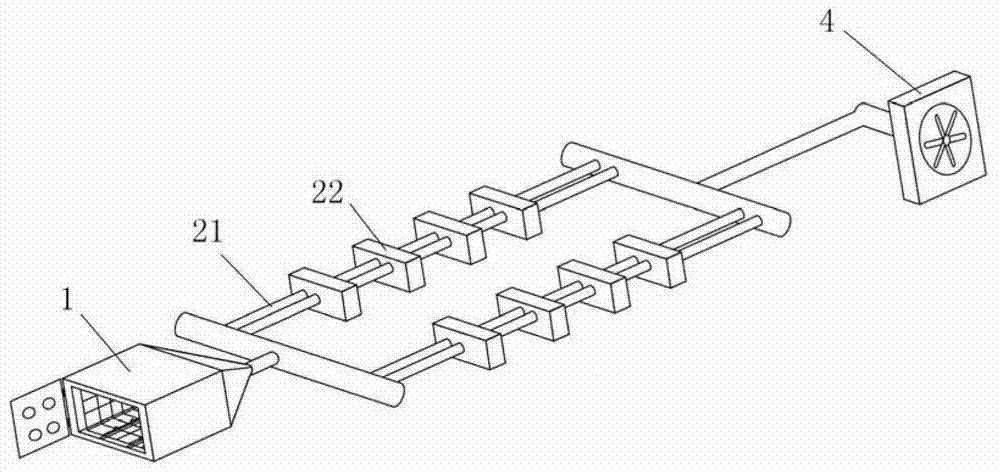

[0031] Such as figure 2 , 5 As shown, the radiator includes a plurality of radiating pipes 21 and a plurality of fireboxes 22, the firebox 22 is a hollow cavity, and two ends are provided with pipe connection ports 23 connected with the radiating pipes; the fireboxes 2 are connected end to end through the radiating pipes The main body of the radiator is constituted; the heat dissipation pipe 21 in the radiator is detachably connected with the fire box 22 and the heat dissipation pipe is detachably connected with the heat dissipation pipe.

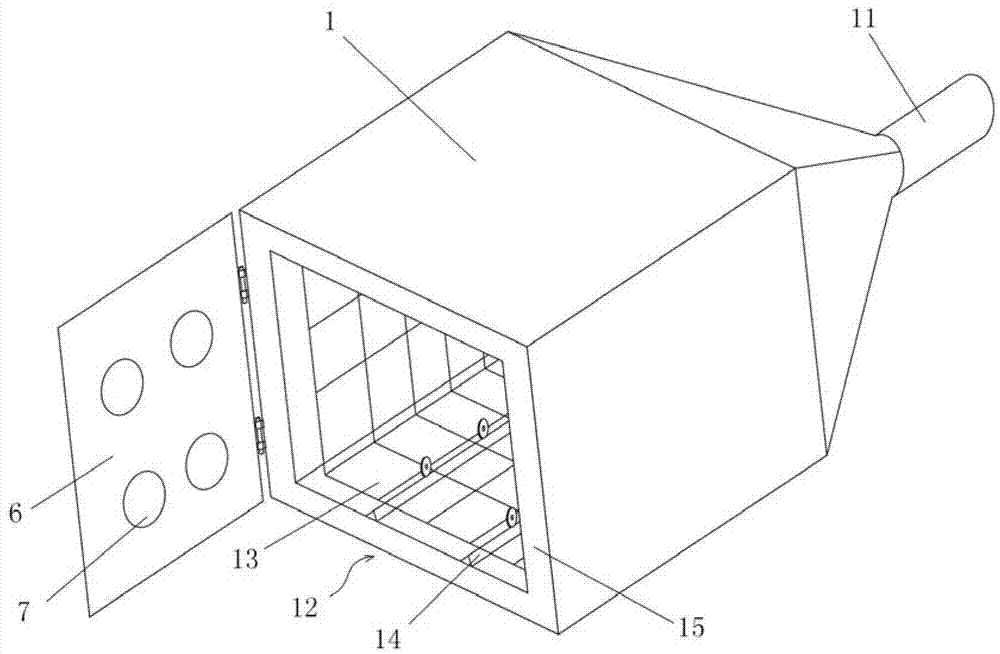

[0032] Such as image 3 , 4 As shown, the stove 1 is composed of a shell 15 to form a stove body, and the shell is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com